Function:

Initial voltage is active for the time set in parameter 120

Start delay , after a start command. This parameter can

be used for example for lifting/dropping applications

(conical anchor motors).

Description of choice:

Set the required voltage necessary to cut out the me-

chanical brake. It is assumed that parameter 121 Start

function, is set to Start frequency/voltage clockwise [3]

or Start frequency/voltage in reference direction [4] and

that in parameter 120 Start delay a time is set, and that

a reference signal is present.

132 DC brake voltage

(DC BRAKE VOLTAGE)

Value:

0 - 100% of max. DC brake voltage

0%

Function:

In this parameter, the DC brake voltage is set which is

to be activated at stop when the DC brake frequency

set in parameter 127 DC brake cut-in frequency is

reached, or if DC braking inverse is active via a digital

input or via serial communication. Subsequently, the

DC brake voltage will be active for the time set in pa-

rameter 126 DC brake time.

Description of choice:

To be set as a percentage value of the max. DC brake

voltage, which depends on the motor.

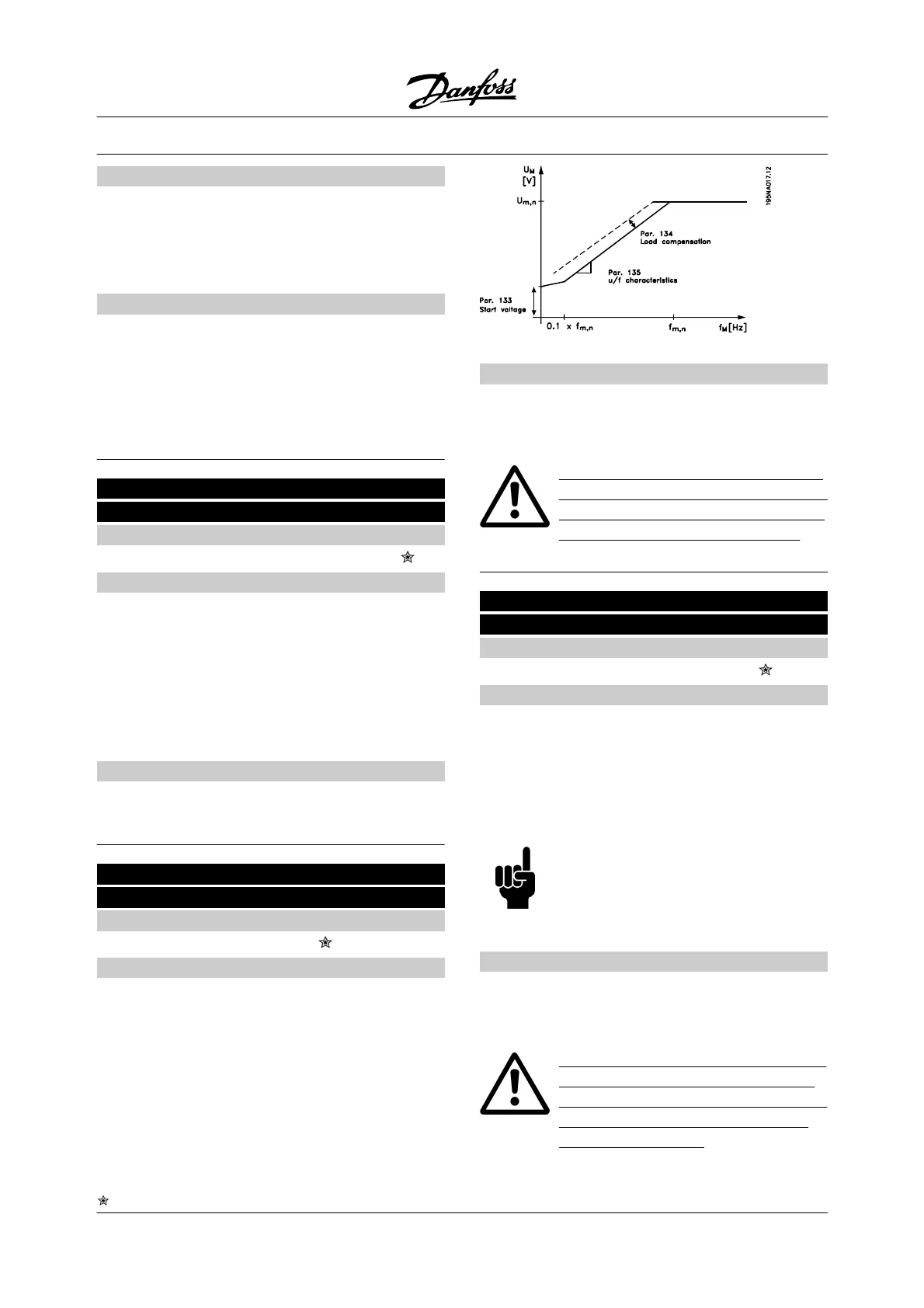

133 Start voltage

(START VOLTAGE)

Value:

0.00 - 100.00 V

Depends on unit

Function:

A higher start torque can be obtained by increasing the

start voltage. Small motors (< 1.0 HP) normally require

a high start voltage.

Description of choice:

The factory setting will be suitable for must applica-

tions, the value may need to be increase gradually for

high torque application.

Warning: If the use of start voltage is ex-

aggerated, this may lead to over-energiz-

ing and overheating of the motor and the

variable frequency drive may cut out.

134 Load compensation

(LOAD COMPENSATIO)

Value:

0.0 - 300.0%

100.0%

Function:

In this parameter, the load characteristic is set. By in-

creasing the load compensation, the motor is given an

extra voltage and frequency supplement at increasing

loads. This is used e.g. in motors/applications in which

there is a big difference between the full-load current

and idle-load current of the motor.

NOTE

If this value is set too high, the variable

frequency drive may cut out because of

overcurrent.

Description of choice:

If the factory setting is not adequate, load compensa-

tion must be set to enable the motor to start at the given

load.

Warning: Should be set to 0% in connec-

tion with synchronous and parallel-cou-

pled motors and in the case of quick load

changes. Too high load compensation

may lead to instability.

VLT

®

2800 Series

= factory setting, () = display text, [] = value for use in communication via serial communication port

48 MG.27.A2.22 - VLT

®

is a registered Danfoss trademark

Loading...

Loading...