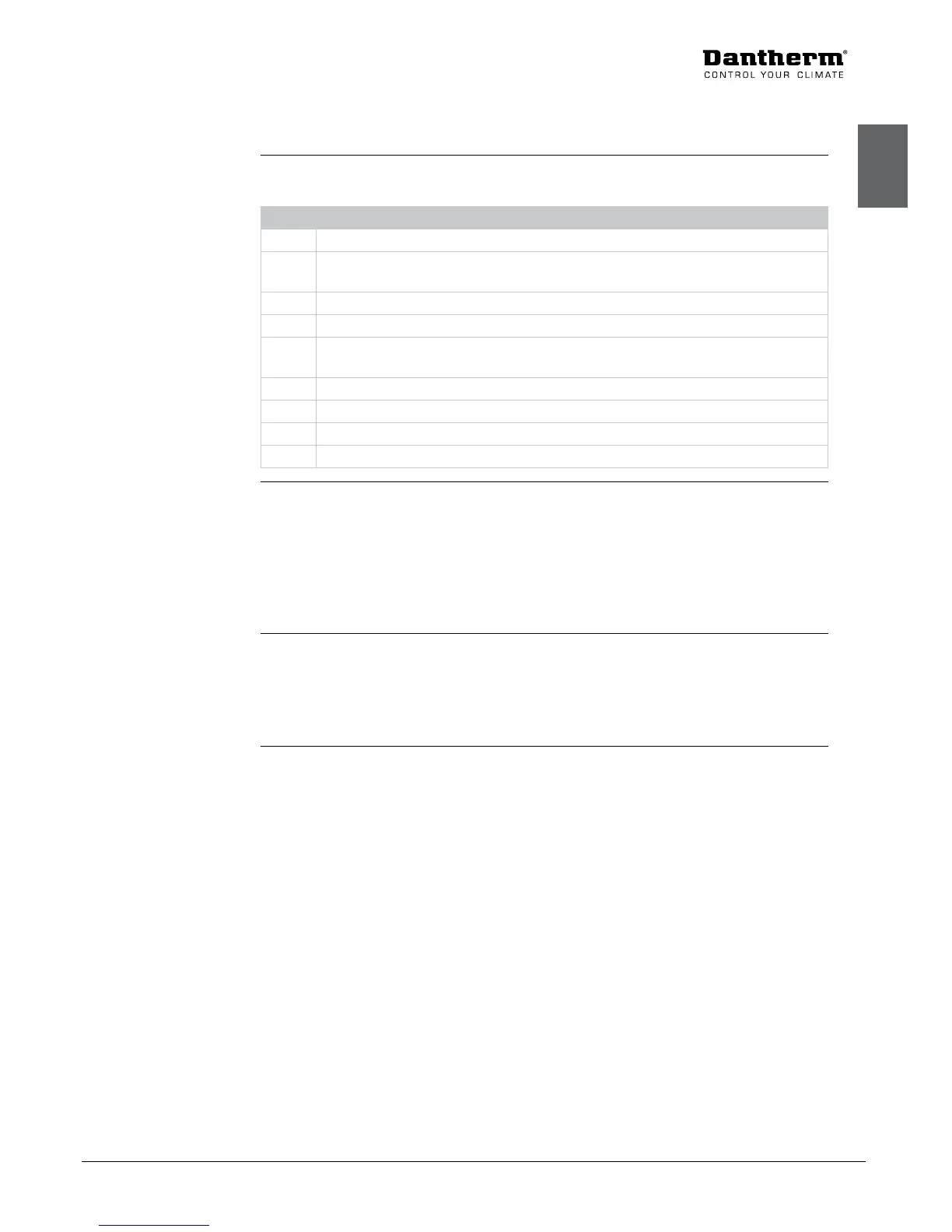

Preventative maintenance, continued

The unit must be inspected prior to any re-assembly and put back into service. Please follow

below steps:

Phase Description

1 Are the fans clean and free of any corrosion?

2 Are the coolant pipes free of obstructions, damage, corrosion and show no

obvious signs of leakage?

3 Are the coil lamellars clean and undamaged?

4 Are all fan blades free of any obstructions, cracks or missing blades?

5 When rotating the fans with the ngers, do the fans rotate freely without

vibrations and noise?

6 Is all wiring and insulation undamaged?

7 Are all connectors secured properly and in good condition?

8 Inspect the drain hose (if any) for damages.

9 Are any alarms visible on the controller? See page 9

The cooling circuit is designed for long durability, and is comprised of a few components.

Any test of the circuit should be conducted only if a relevant problem has arisen.

Open the unit outside cover by removing the two screws in the lower part.

Locate the service valve and connect a pressure gauge. Conrm that the pressure is aligned

with the present temperature according the read pressure.

Please be aware that with very low amount of refrigerant, its critical to use short hoses to the

pressure gauge meter.

The compressor’s safety switch (Klixon) can be tested manually. Make sure that the unit’s

cooling circuit is working before initiating this test.

Cover the condenser air inlet in the bottom of the outer cabinet with a piece of plastic

or something similar. Bring the unit into continuous operation (lower setpoint inside the

shelter), and expect shut down within a maximum one hour. If not, the switch is not working.

Inspection

Test cooling circuit

Test safety shut

down

Loading...

Loading...