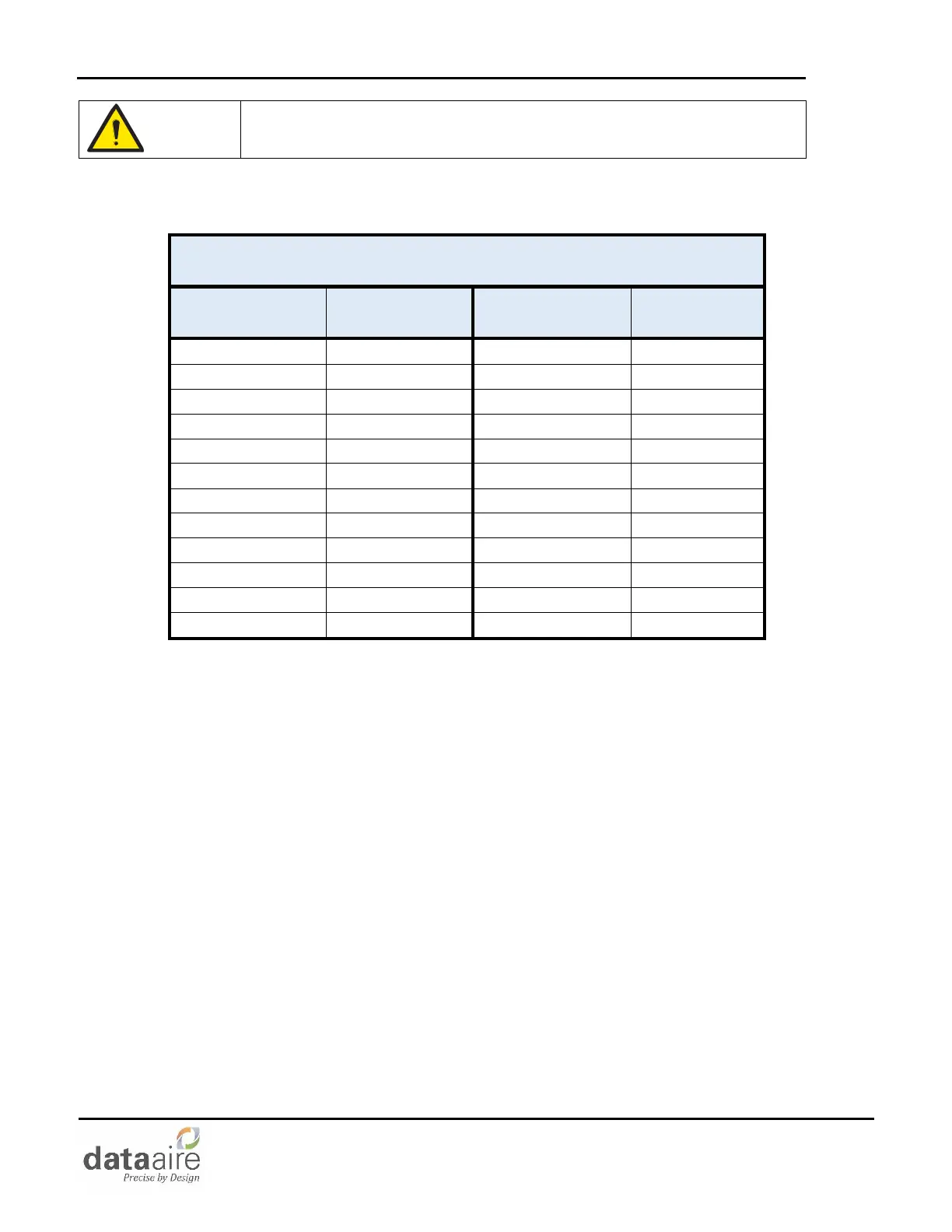

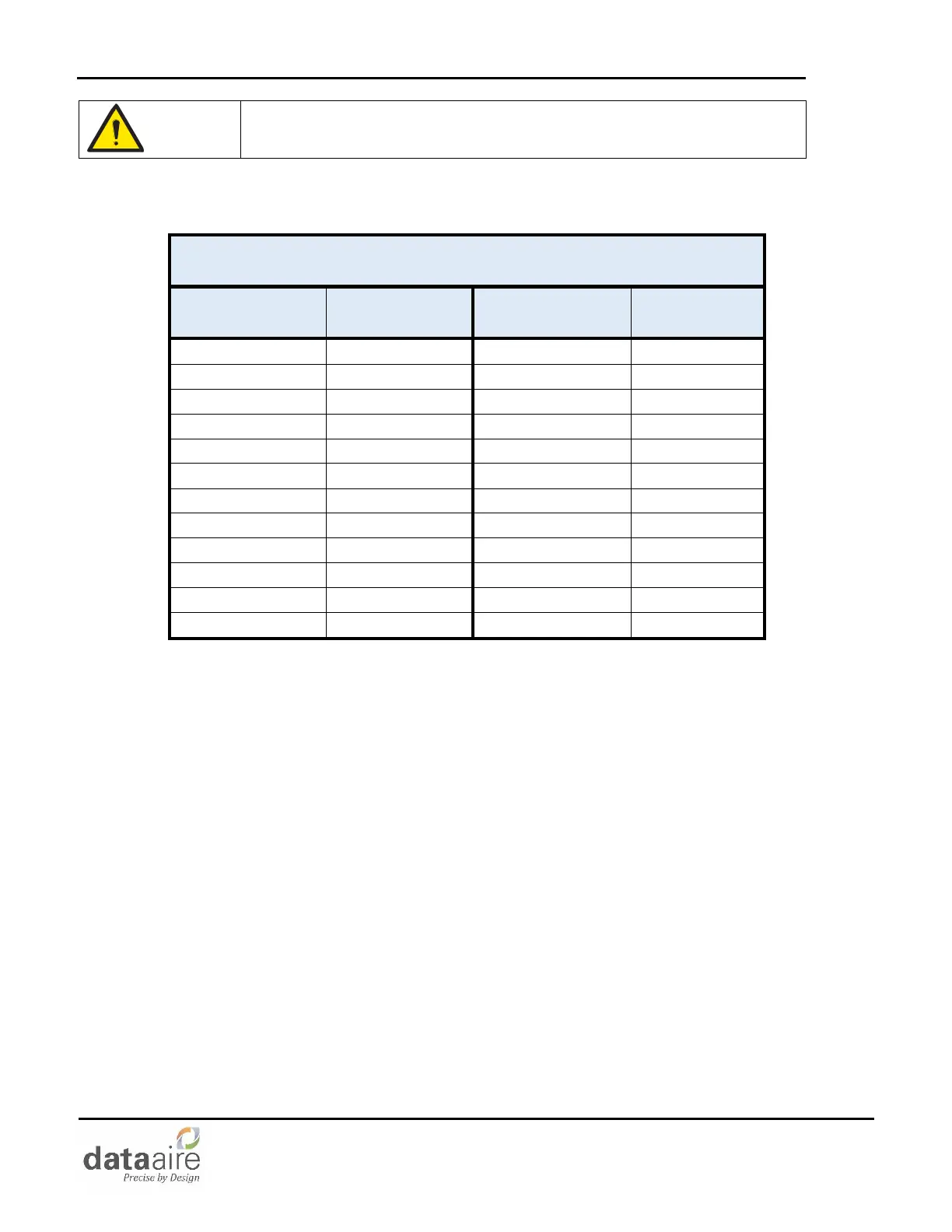

Oil addition is calculated based on refrigerant charge, shown in the table below:

Table 1 - Additional Oil Required When Charging

4.1.3 Flooded System Charging

Flooded type systems are supplied with optional liquid receiver and head pressure control valve. When the ambient

temperature falls during cold weather, the head pressure control valve will regulate the flow of refrigerant to ensure

nearly constant receiver pressure. The condenser is partially flooded with liquid refrigerant in cold weather. In warm

weather the extra refrigerant is stored in the receiver.

Flooded systems require more refrigerant than fan speed control systems. Connect the pressure gauge manifold

set to the high and low ports near the compressor. Connect the charging line to the refrigerant tank and set for

liquid feed. Open the refrigerant tank valve and purge the line. Open the high side valve on the manifold only and

allow the refrigerant to flow until the system pressure equalizes. At this point the system will have 75 to 85% of the

total refrigerant charge. Start the evaporator motor. Start the compressor and check the operating pressures and

temperatures.

A quick and easy way to run the compressor is using the manual switch on the unit’s microprocessor. Switch the

compressor manual switch to the ON position. All automatic control is disabled but safety switches will remain

functional. Manual Control mode in dap4 or Mini-dap4 Menu I can be used to run fan and compressor as well.

For units with blowers, switch the blower manual switch to the “ON” position.

For units with plug fans, using the manual switch operation will not bring the fans to full speed. Enabling the

BLOWER manual mode switch engages the system powering the high voltage to the plug fans but sets the control

Loading...

Loading...