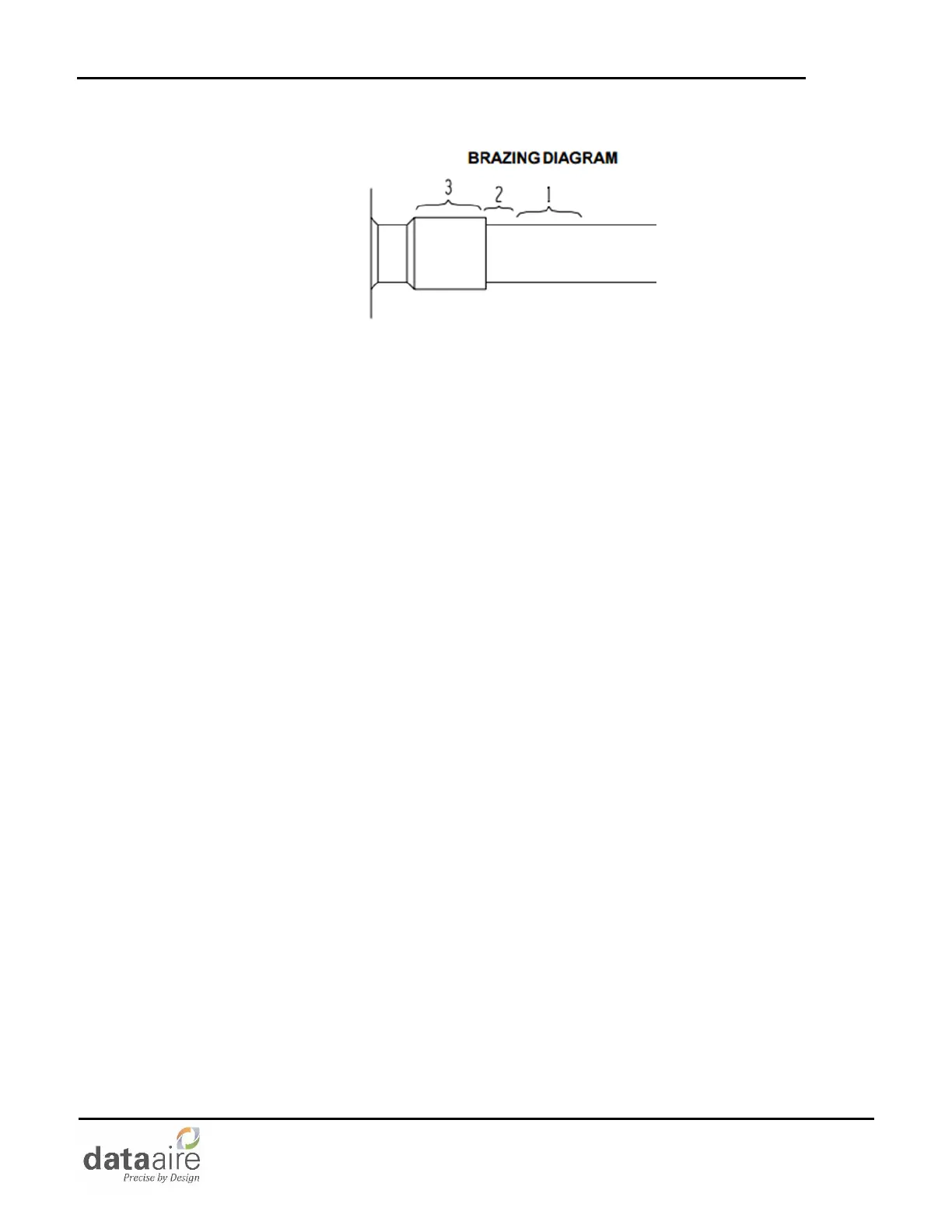

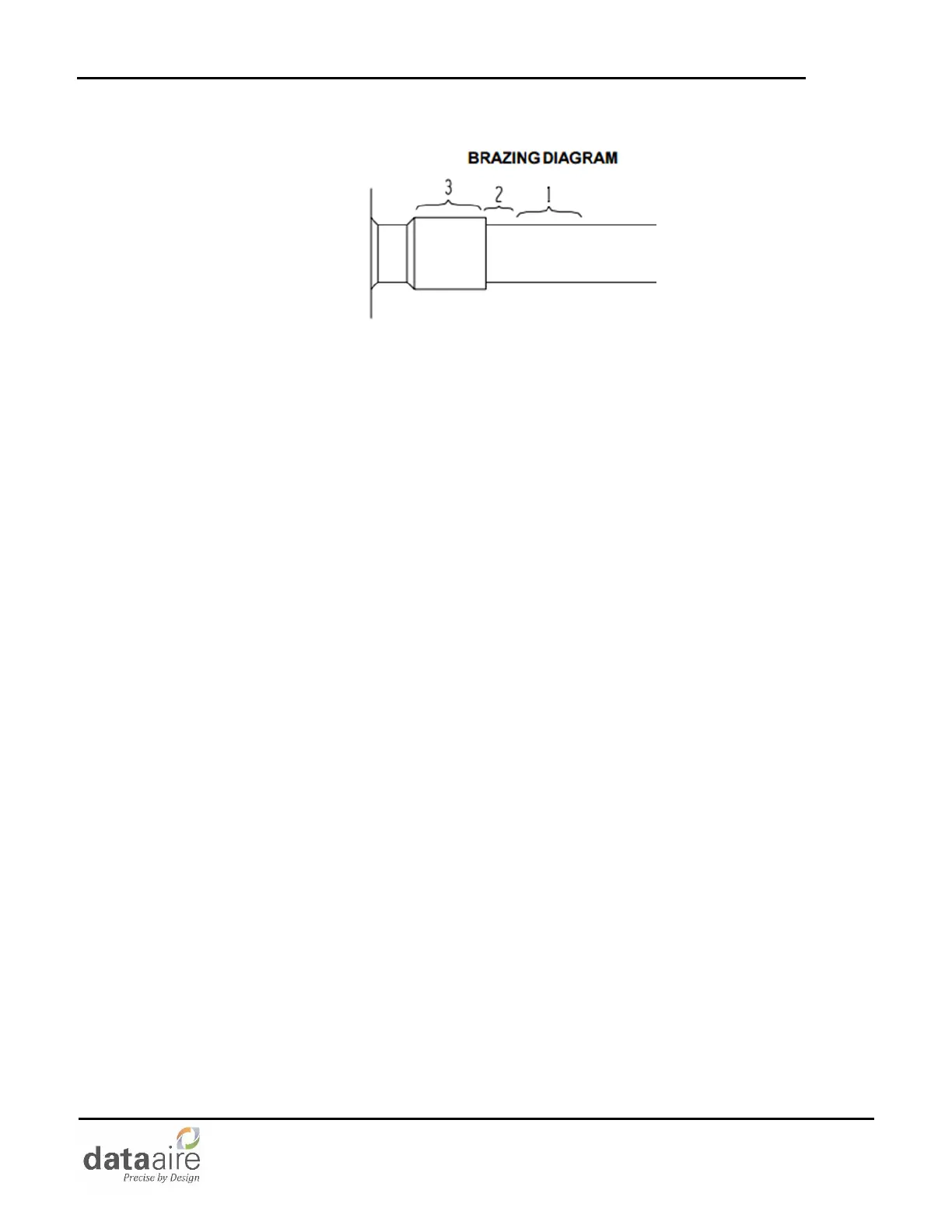

b. Using a torch, apply heat in area 1. As tube approaches brazing temperature, move the torch flame

to area 2.

c. Heat area 2 until braze temperature is attained, moving torch up and down and rotating around

tube as necessary to heat tube evenly. Add braze material to the joint while moving torch around

joint to flow braze material around circumference.

d. After braze material flows around joint, move torch to heat area 3. This will draw the braze material

down into the joint. The time spent heating area 3 should be minimal.

5. Reconnect all electrical wiring to original condition. Compressor must be grounded to true earth ground

after replacing original compressor.

6. Check the rotation direction of three phase scroll compressors:

a. Scroll compressors will compress in one rotational direction only. Direction of rotation is not an

issue with single phase compressors, because they will always start and run in the proper direction.

Three phase compressors will run in either direction depending upon the phasing of the input

power.

b. Verification of proper rotational direction must be made by observing that the suction pressure

drops, and the discharge pressure rises when the compressor is energized. Reverse rotation also

results in an elevated sound level as well as substantially reduced current draw compared to

forward rotation. Operating a scroll compressor in reverse rotation for an extended period will

result in compressor failure.

c. If the compressor is rotating backwards, reverse any 2 of the 3 input wires will cause the compressor

to rotate in the correct direction.

7. Evacuate and charge the system with the specified quantity of refrigerant.

8. Adjust refrigerant level as needed.

9. Check compressor suction and discharge pressure.

10. Check sub cooling and super heat values.

11. Check compressor amps.

12. Check high- and low-pressure switches.

13. Check crankcase heater.

14. Check compressor for vibration, noise or other issues after startup.

7.18.3 Refrigerant Filter Drier

Factory installed refrigerant filter driers do not normally require maintenance. When replacing compressors or

other repairs that open the refrigeration system to atmosphere, it is advisable to replace the filter drier. The

equivalent type and size should be used.

Loading...

Loading...