4

Pipe Connection

A set of applicable (European or Australian) barrel unions are provided for connecting to the

piping from the pool. The pumps are designed to accept the following PVC pipes by tting the

pipe to either the inside or the outside of the union tail.

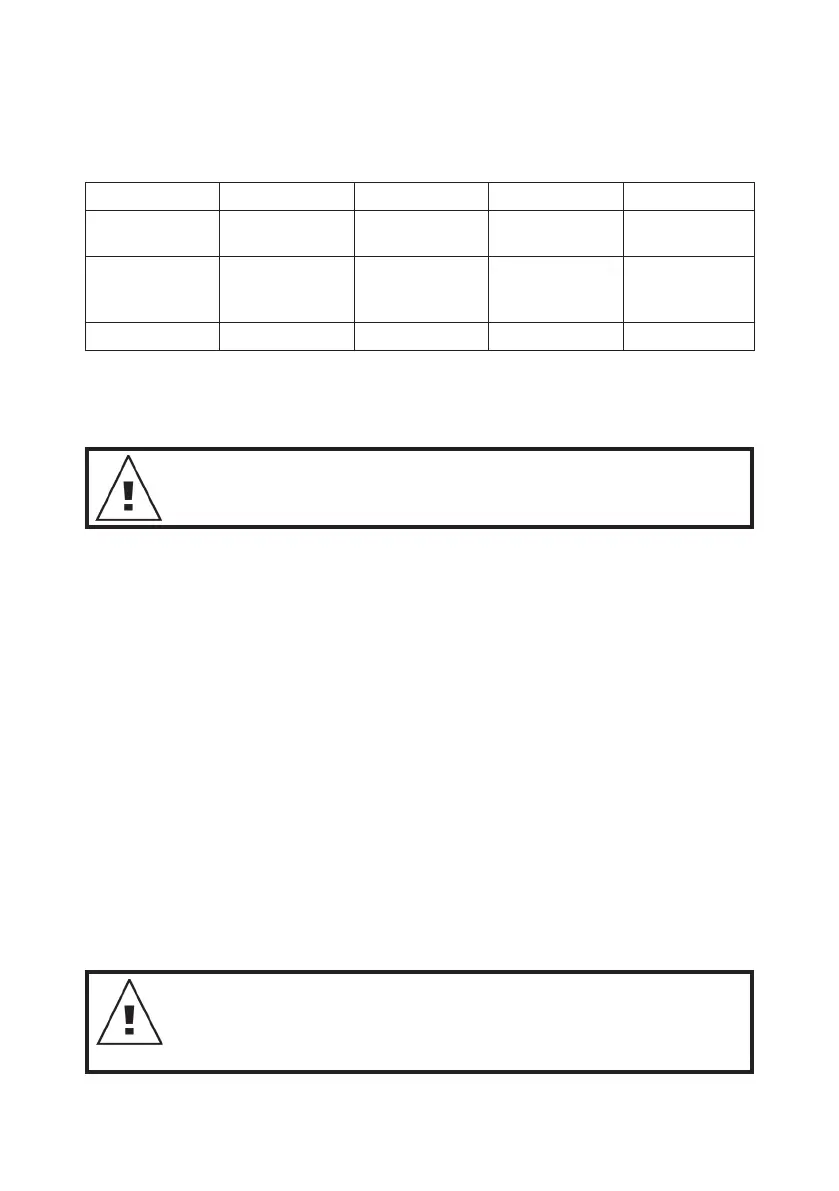

Model Inlet PVC Position Outlet PVC Position

SLS100-300

1.5” pipe

or 2” tting

ID

OD

1.5” pipe

2” tting

ID

OD

SLL200

1.5” pipe

or 2” tting

or 2” pipe

ID

OD

ID

1.5” pipe

2” tting

2” pipe

ID

OD

ID

SLL300/400 1.5” pipe ID 2” pipe ID

The use of any pipe smaller than those specied above is not recommended. Suction piping

should be free from all air leaks and any humps and hollows which cause suction difculties.

The discharge piping from the pump outlet should be connected to the inlet connection on the

swimming pool lter (usually at the lter control valve).

Barrel unions need to be hand tightened. No sealant, glues or silicones

are required.

Starting the Pump

To operate efciently and prevent pump damage there must be a free ow of water to and

from the pump. Before starting ensure that:

- all pipework is correctly sealed.

- the pool/spa water level is at the correct height.

- that all appropriate valves are open and there is nothing preventing the ow of water

through the system.

1. First prime the pump by removing the strainer basket lid and lling the strainer basket

area with water. Replace the lid, ensuring that it seals on the large oring.

2. Connect to the power supply and switch on.

3. Allow the pump to run, so that any air trapped may be expelled.

4. If prime is not established within approximately two minutes, as evidenced by a strong ow

of water, switch off the pump and repeat the procedure. Continued evidence of air under

the strainer basket lid indicates an air leak in the suction piping which should be rectied

to avoid pump damage.

Pump Operation

For optimum pump performance, the strainer basket housing should always be full of water

and free from air bubbles. The water level of the pool should always be maintained to at least

halfway up the skimmer box ensuring water is in the pump at all times. From time to time it

may be necessary to re-prime the pump. This should be carried out as described above.

Never run pump dry. Running the pump with no water may damage the

mechanical seals, causing leakage and ooding. Dry running damage and

associated damage is not covered under warranty. Silensor incorporates

dry run protection which will need to be re-set by turning off the power

supply, reducing potential damage.

Loading...

Loading...