Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

• The tubes in the peristaltic pumps should

be replaced at least two times a year.

• The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

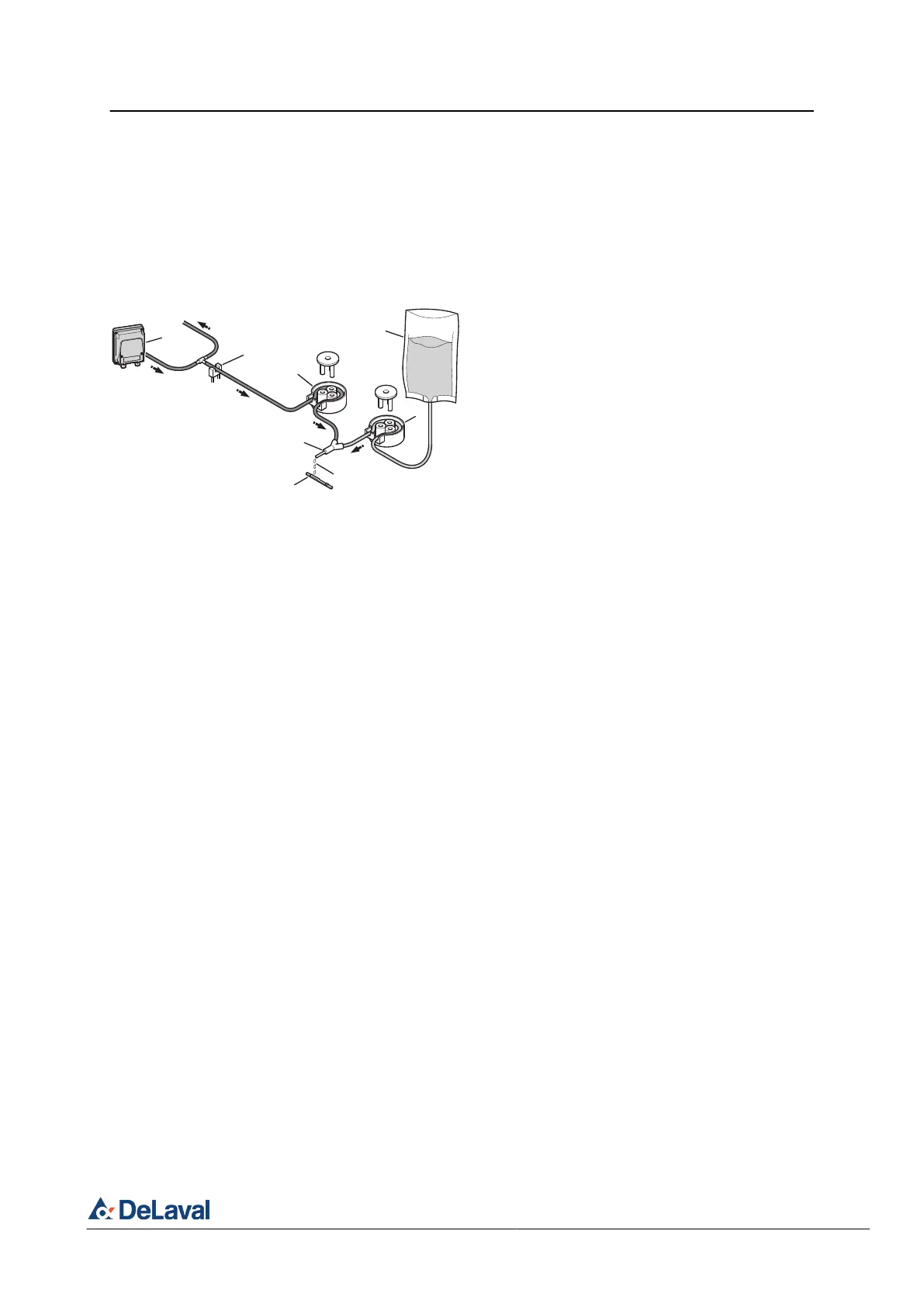

3 Herd Navigator 100 sampling

workflow

The Herd Navigator 100 sampling routine is per-

formed in the VMS when the cows are milked.

1. Herd Navigator 100 receives milk from the

VMS controller via the single sample out-

take pump (SSO) (A).

2. The peristaltic milk pump (C) uses the new

milk to clean the tube from milk residues

from the previous sample and saves milk

for the new analysis. The needle (G) is in

the drain position and the first milk goes to

the drain.

3. The peristaltic diluent pump (E) runs at the

same time as the peristaltic milk pump (C).

The speed of the pumps is set by a mixing

ratio.

4. The mixing chamber (F) mix milk and

diluent (D).

5. The pumps stop, and needle (G) and stick

(H) move to the dose position.

6. The pumps start again and a dosage of 45

microliters of mixed milk and diluent is

applied to the stick (H).

7. A chemical reaction takes place in the stick

(H) and it is coloured.

8. The incubation time (around 5.5 min)

begins.

9. The stick (H) moves to the optical reader

which scans the intensity of the stick colour.

The measurement of the progesterone

concentration is then transferred to the bio-

model software.

10.The peristaltic milk pump (C) runs to empty

the tubes from residues and sends it to the

drain (the needle is in drain position).

11.The biomodel processes the analysis

results and communicates them to the Del-

Pro farm manager.

The Herd Navigator 100 is cleaned in the ordi-

nary VMS cleaning/rinse. During cleaning, the

needle is in the drain position throughout the

whole process.

276559

Fig. 8: The sampling workflow for Herd Navigator

100.

A: SSO pump

B: Optical Fluid sensor

C: Peristaltic Milk Pump

D: Diluent

E: Peristaltic Diluent Pump

F: Mixing Chamber

G: Needle

H: Stick

Cleaning

DeLaval Herd Navigator™ precision analytics 100

General description

© DeLaval 2021.

2021-05-10, Version 3 18 (44) 2800008901

Loading...

Loading...