Preliminary

941322_VMS Instruction Book 2006.pdf2009-09-07

No. Name Range Default Description/optionsNo. Name Range Default Description/options

0 = no acidic cleaning0 = no acidic cleaning

1 = one alkaline, one acidic cleaning1 = one alkaline, one acidic cleaning

2 = two alkaline, one acidic cleaning2 = two alkaline, one acidic cleaning

3 = etc.3 = etc.

Maintenance an calibration

The following points are important to sustain

correct dosing of etergents. Note that

these two tasks should be performed by an

authorised DeLaval service engineer.

• The tubes in the peristaltic pumps should

be replaced at least two times a year.

• The dosing volume (P6-P8) of the

detergent pumps should be checked

every third month. The dosing capacity

(P32-P34) may need to be adjusted.

Starting cleaning or rinsing

from the touch screen

Note: Any ongoing backflush process must

first be finished before cleaning or rinsing

can be started.

1. Ensure that the milking station is in

manual mode.

2. Remove any cow that might be in the

milking station.

After treatment window

Note: Both gates should be closed to

prevent a cow from entering before the

system cleaning has been started. Closing

and opening gates is done in the Stall

control window.

3. Press the tab After Treatment on the

touch screen to display the After treatment

window.

4. In the After treatment window, press the

Cleaning and Rinsing button. This will open

the Cleaning and rinsing window.

4. Open the side of the new diluent box to

retrieve the diluent connector (D).

5. Break the diluent sealing by bending the

tube more than 90° until liquid floats around

the connector.

6. Slide the diluent box (C) into the slot.

7. Connect the diluent connector (D) to the

flow module diluent connector by twisting

the two parts together in a clockwise

motion, see (B) in Fig. 20. This automati-

cally opens the valve in the diluent connec-

tor.

Note! To prevent that milk sucks into the

diluent and contaminate the diluent, it is

important to disconnect the diluent connec-

tor in case the flow module is removed.

Contaminated diluent will destroy the func-

tion of the diluent and the sampling results

will be inaccurate.

No 3 Fat sampling procedure with an SSO

pump and Herd Navigator 100

276673

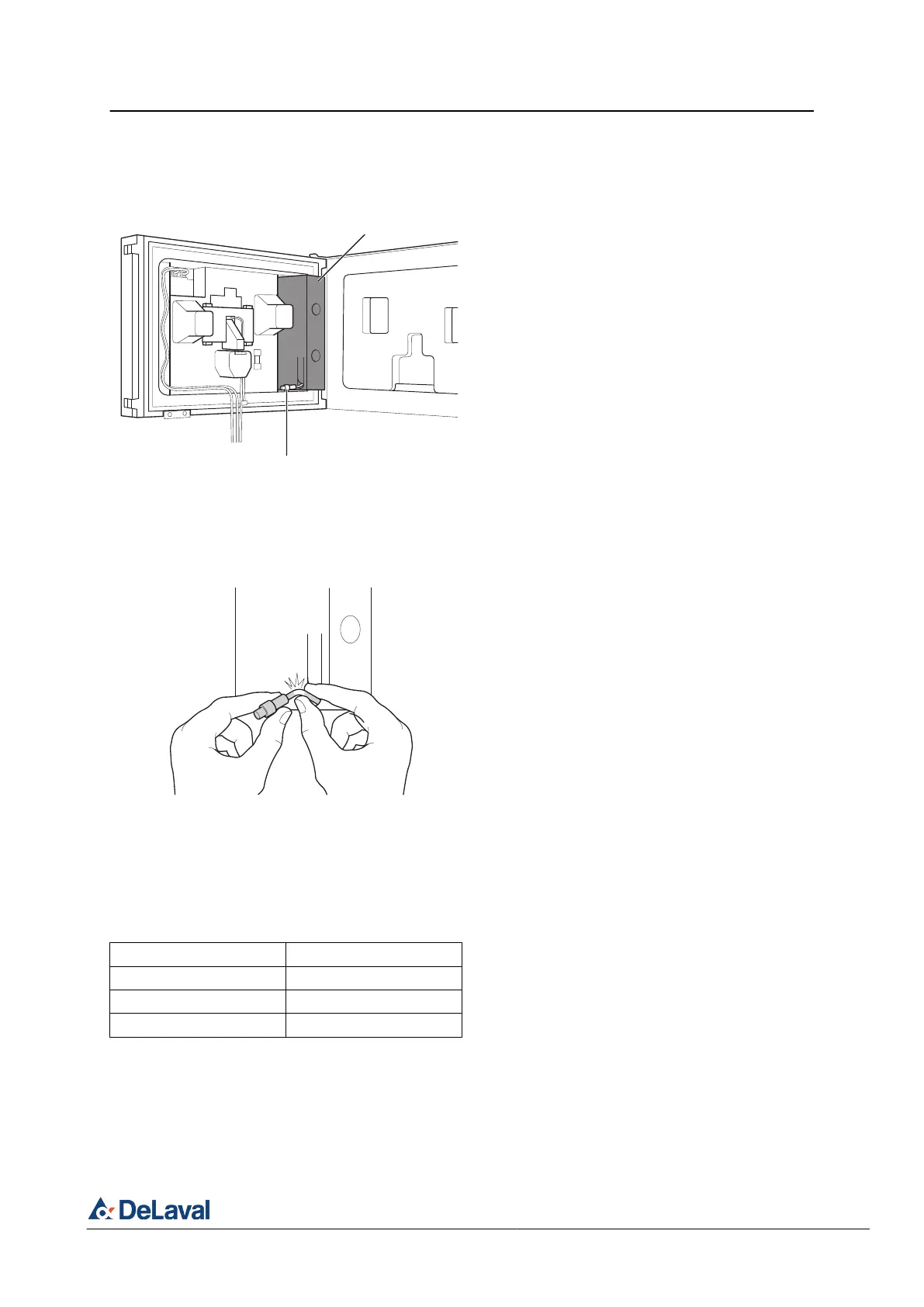

Fig. 21: Placement of the diluent box.

277311

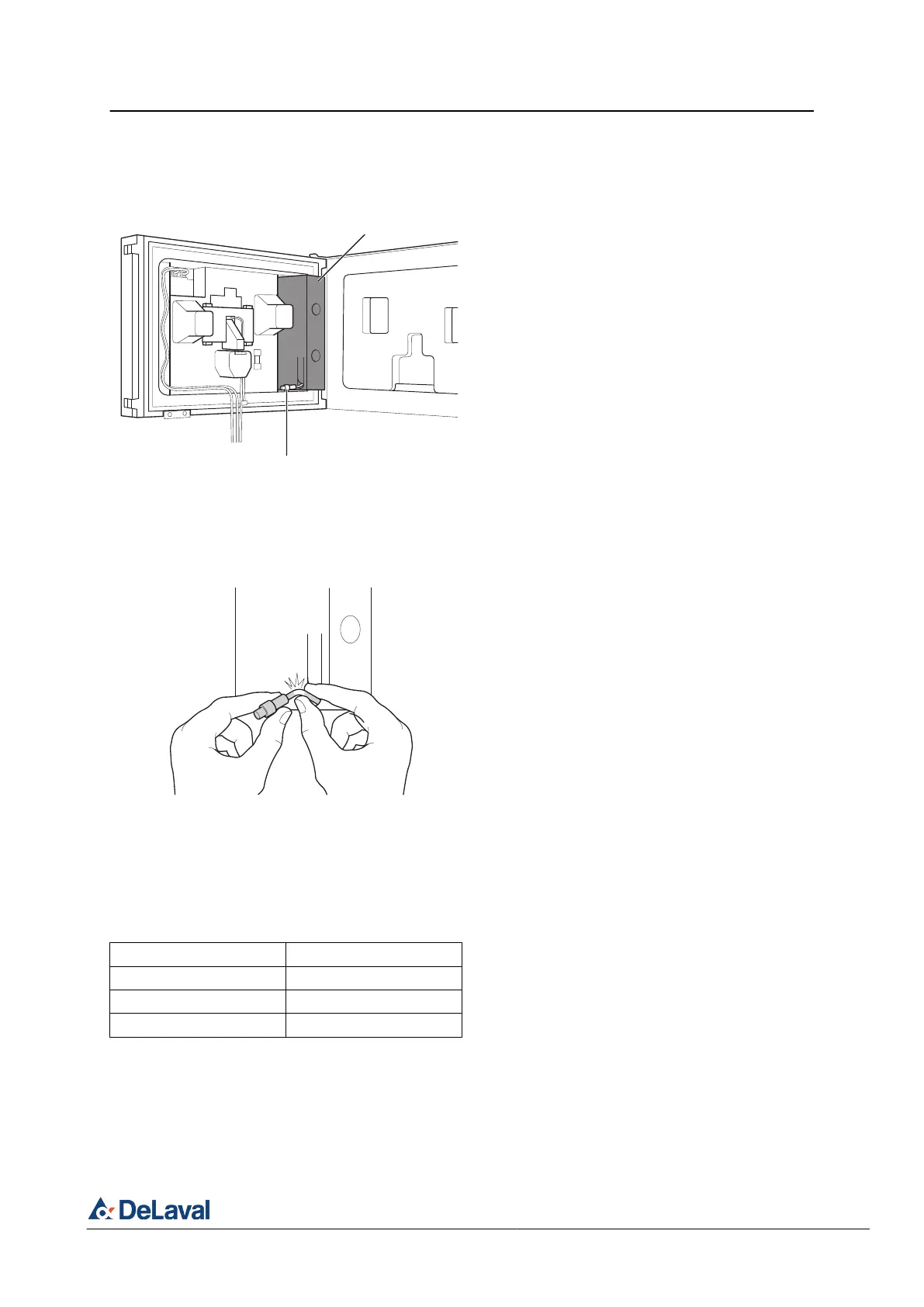

Fig. 22: Breaking the diluent sealing.

Frequency -

Max. interval Monthly

Estimated time: -

Service type: Verify

DeLaval Herd Navigator™ precision analytics 100

Operator's maintenance

© DeLaval 2021.

2021-05-10, Version 3 35 (44) 2800008901

Loading...

Loading...