- 3 -

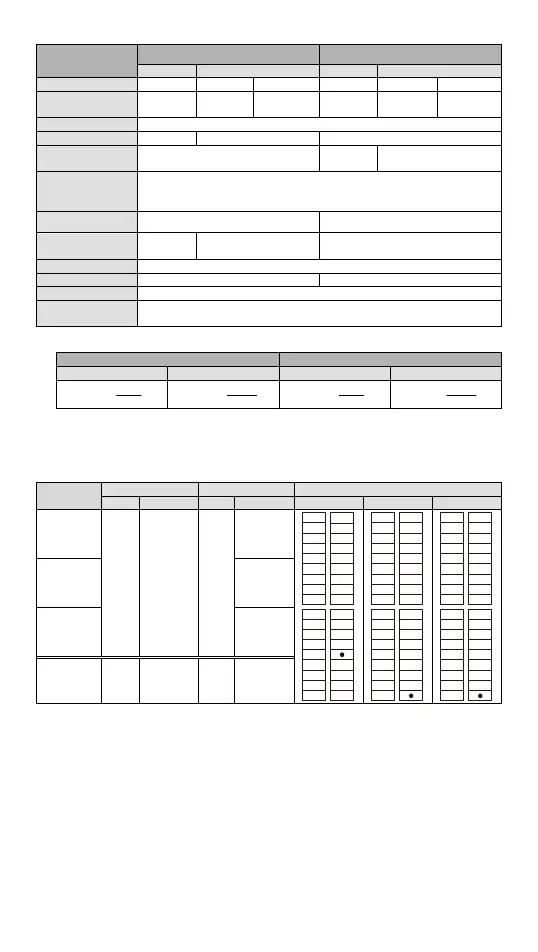

A/D and D/A Specifications

Items

Analog Input (A/D) Analog Output (D/A)

Voltage Current Voltage Current

Analog I/O range ±10V ±20mA 4 ~ 20mA

#1

±10V 0 ~ 20mA 4 ~ 20mA

#1

Digital conversion

range

±2,000 ±2,000 0 ~ +2,000 ±2,000 0 ~ +4,000 0 ~ +4,000

Resolution

#2

12-bit

Input impedance > 1MΩ 250Ω -

Tolerance carried

impedance

- ≥ 5KΩ ≤ 500Ω

Overall accuracy

Non-linear accuracy: ±1% of full scale within the range of PLC operation

temperature

Maximum deviation: 1% of full scale at 20mA and +10V

Response time 2ms (set up in D1118)

#3

2ms

#4

Absolute input

range

±15V ±32mA -

Digital data format

2’s complement of 16-bit, 12 significant bits

Average function Provided (set up in D1062)

#5

-

Isolation method No Isolation between digital circuit and analog circuit

Protection

Voltage output has short circuit protection, but a long period of short

circuit may cause internal wire damage and open circuit of current output.

#1: Please refer to the detailed explanation of D1115.

#2: Resolution formula

Analog Input (A/D) Analog Output (D/A)

Voltage Current Voltage Current

)

4000

20V

5mV(

)

4000

40mA

μΑ(10

)

4000

20V

5mV(

)

4000

20mA

μΑ(5

#3: When the scan period is longer than 2ms or the set value, the setting will follow the scan

period.

#4: When the scan period is longer than 2ms, the setting will follow the scan period.

#5: When the sampling range is “1”, the present value will be read.

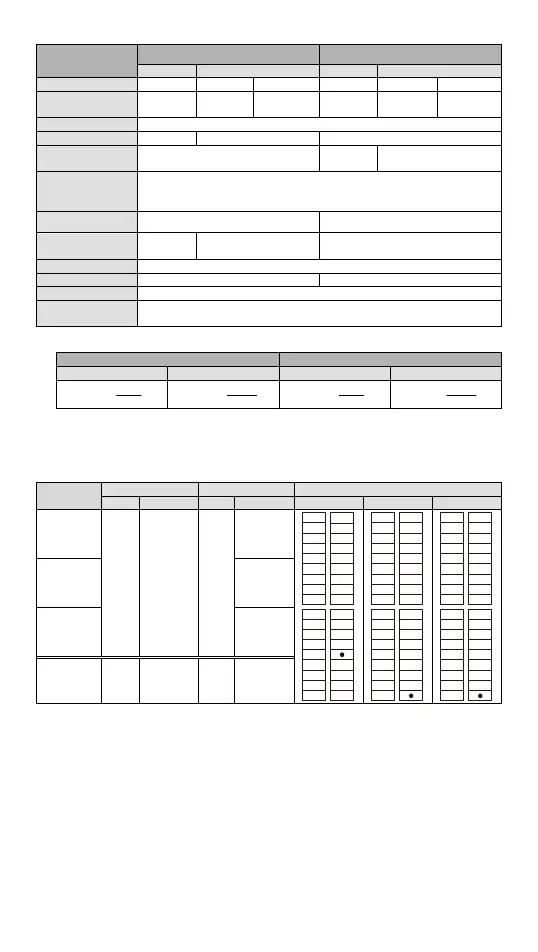

I/O Configuration

Model

Input Output I/O configuration

Point Type Point Type Relay NPN PNP

20SX211R

8

DC

(Sink Or

Source)

6

Relay

V0+

I0+

VI0-

V1+

I1+

VI1-

V2+

I2+

VI2-

V3+

I3+

VI3-

FE

VO0

VO1

IO1

AG

S/S

X0

X1

X2

X5

X6

X7

Y0

Y1

Y2

Y3

Y4

Y5

X4

C0

C1IO0

X3

V0+

I0+

VI0-

V1+

I1+

VI1-

V2+

I2+

VI2-

V3+

I3+

VI3-

FE

VO0

VO1

IO1

AG

S/S

X0

X1

X2

X5

X6

X7

ZP

Y0

Y1

Y4

Y5

X4

UP

Y3IO0

X3

Y2

V0+

I0+

VI0-

V1+

I1+

VI1-

V2+

I2+

VI2-

V3+

I3+

VI3-

FE

VO0

VO1

IO1

AG

S/S

X0

X1

X2

X5

X6

X7

ZP

Y0

Y1

Y4

Y5

X4

UP

Y3IO0

X3

Y2

20SX211T

NPN

Transistor

20SX211S

PNP

Transistor

SX2-R/T/S 4

Analog

Input

2

Analog

output

Dimension & Installation

Please install the PLC in an enclosure with sufficient space around it to allow heat

dissipation, as shown in the [Figure 5].

Direct Mounting: Please use M4 screw according to the dimension of the product.

DIN Rail Mounting: When mounting the PLC to 35mm DIN rail, be sure to use the

retaining clip to stop any side-to-side movement of the PLC and reduce the chance of

wires being loose. The retaining clip is at the bottom of the PLC. To secure the PLC to

DIN rail, pull down the clip, place it onto the rail and gently push it up. To remove the

PLC, pull the retaining clip down with a flat screwdriver and gently remove the PLC from

DIN rail.

Loading...

Loading...