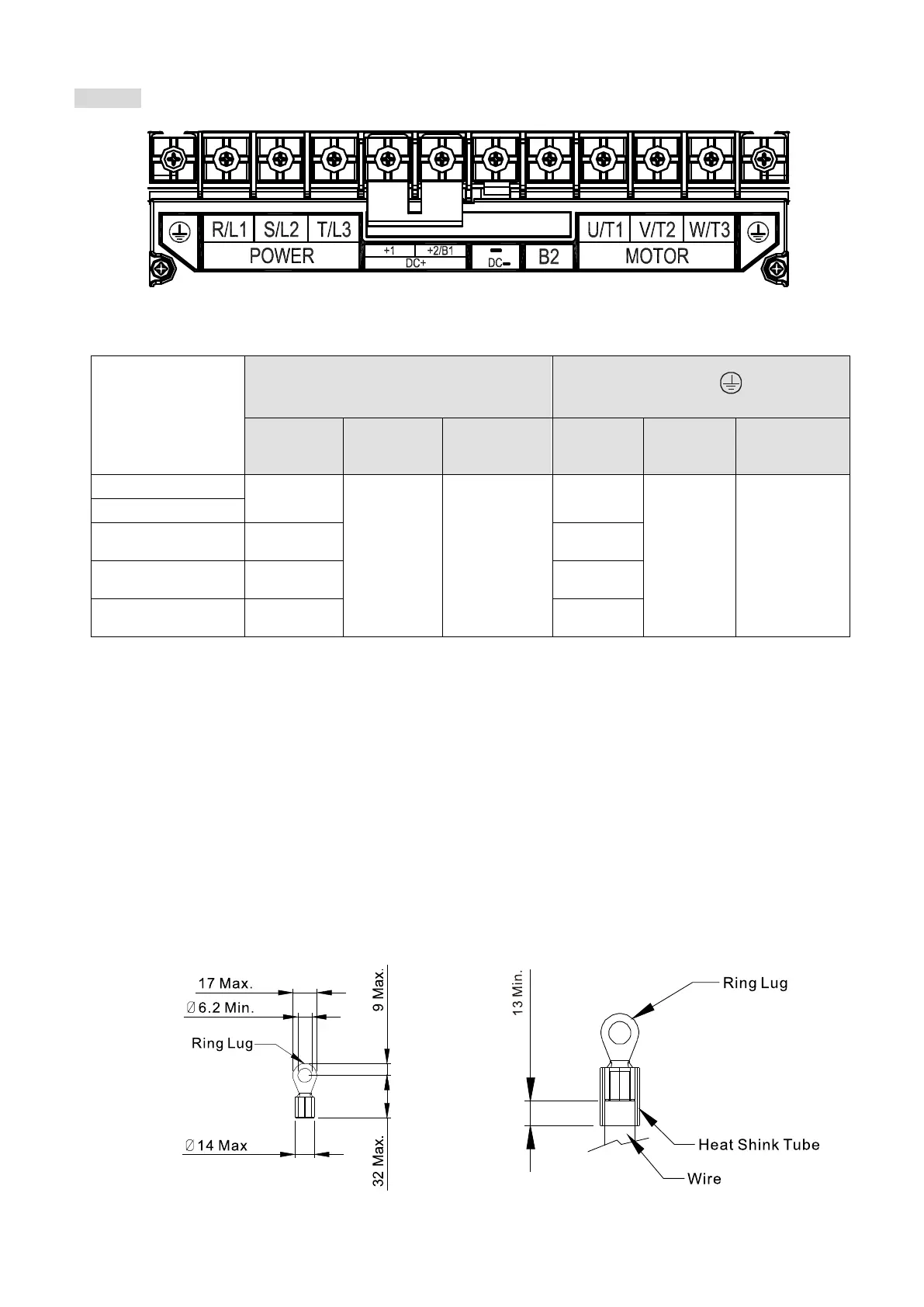

Chapter 4 Main Circuit Terminals | VFD-ED

Frame D

Figure 4-11

Model

Main Circuit Terminals

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

+1, +2/B1, -, B2

Terminal

Min. Wire

Gauge

Max. Wire

Gauge

Tightening

Min. Wire

Gauge

Max. Wire

Gauge

Tightening

21.1 mm²

(4 AWG)

33.6 mm²

(2 AWG)

M6

50 kg-cm

(43.4 lb-in.)

(4.9 N-m)

16 mm²

(6 AWG)

33.6 mm²

(2 AWG)

M6

50 kg-cm

(43.4 lb-in.)

(4.9 N-m)

VFD300ED43S

VFD185ED23S

VFD220ED43S

VFD220ED23S

Table 4-4

For UL installation compliance, select copper wires with voltage rating of 600V and temperature

resistance of 75°C.

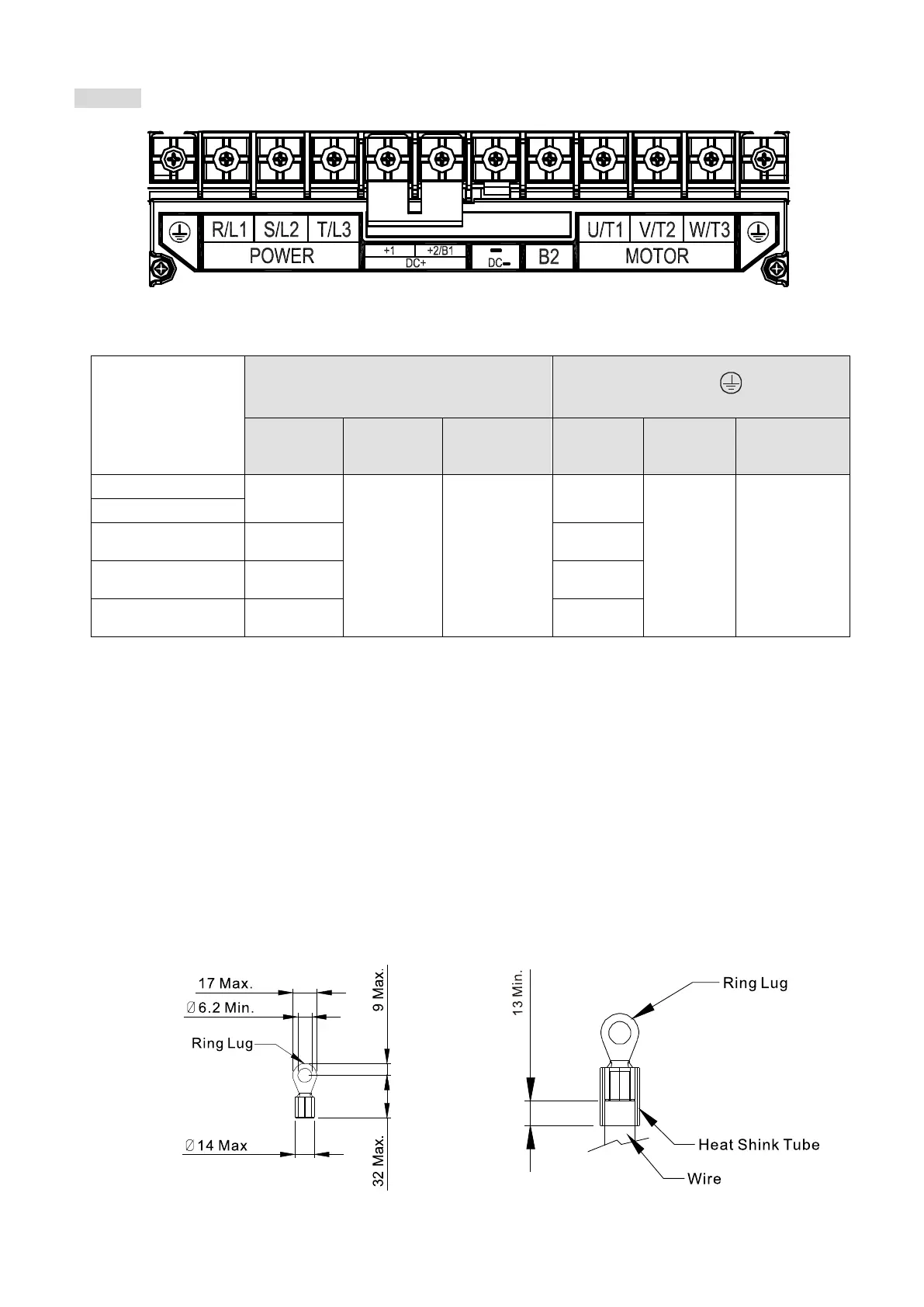

Choose terminal wire size as Figure 4-12 shows.

Use insulated heat shrink tubing that is resistant to at least 600V to comply with UL and CSA

regulations (600 V, YDPU2), as Figure 4-13 shows.

If you install at Ta 50°C environment, use copper wires with voltage rating of 600V and

temperature resistance of 75°C or 90°C.

If you install at Ta 50°C above environment, use copper wires with voltage rating of 600V and

temperature resistance of 90°C or above.

To be UL installation compliant, you must use copper wires when installing. The wire gauge is

based on temperature resistance of 75°C, in accordance with UL requirements and

recommendations. Do not reduce the wire gauge when using high-temperature resistant wire.

Figure 4-12 Figure 4-13

Loading...

Loading...