3. Maintenance and Troubleshooting

C-250E R14 Page 12

3. Maintenance and troubleshooting

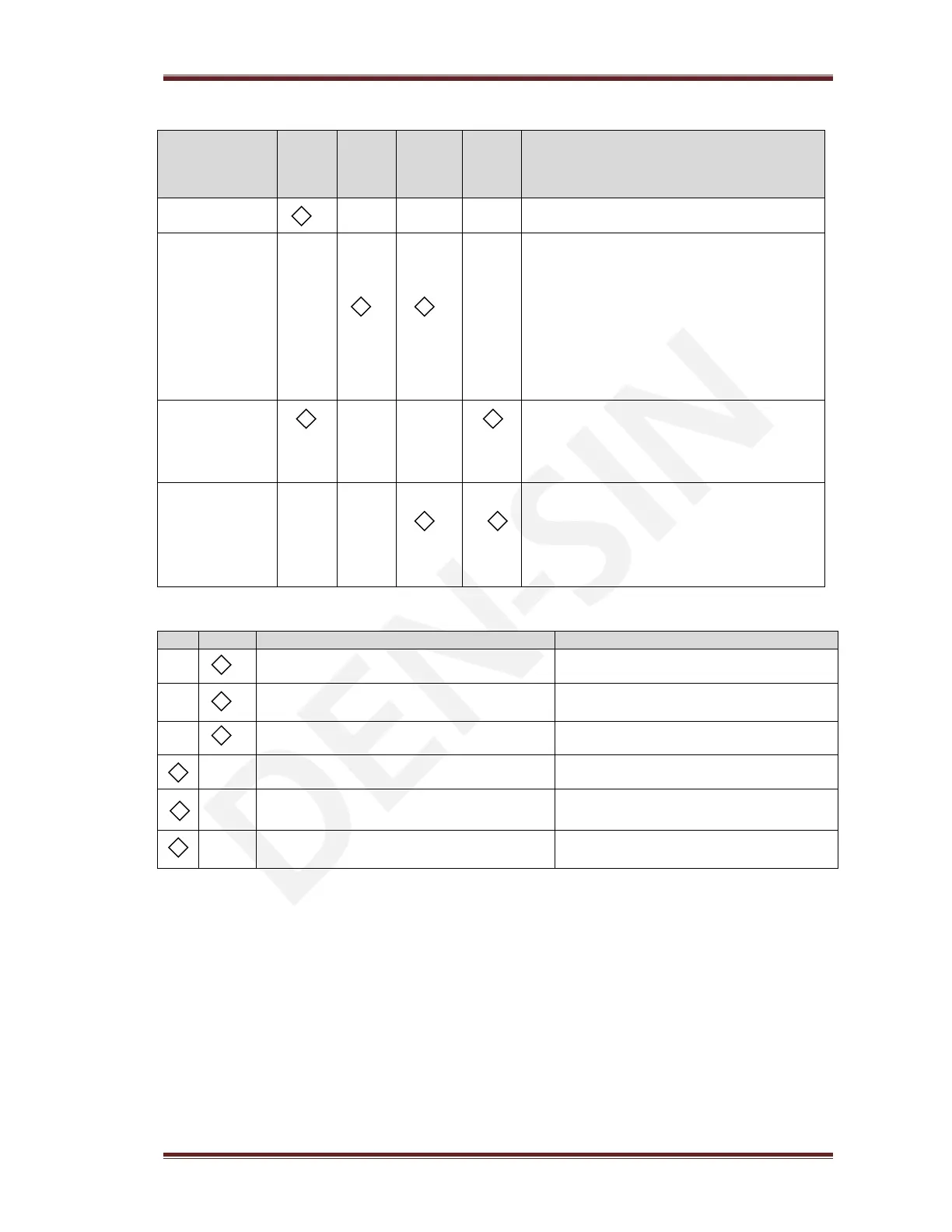

Maintenance Schedule

Regular Service

Period as

indicated

Each

use

1

st

50hrs

Every

month /

Every

When

needed

Procedure / Remarks

Check pump oil

• Top up if necessary.

Change pump oil

Recommended Oil :

SAE 15W40

Usage :

Approx. 0.4kg of

oil

Renewal of oil:

• Turn off High Pressure Cleaner.

• Loosen bolt(Hex) at bottom of pump housing.

• Drain oil into a waste oil-tray.

• Tighten bolt(Hex)

• Add oil through pump inlet on top of the pump

until the red point of the oil control glass has

been reached.

Notice:

Do not dispose of used oil in drain.

Cleaning of

machine

• Use damp cloth to wipe the cabinet and handle

bar.

Notice:

Do not use detergent cleaning chemicals

Cleaning of

motor fan

(

to ensure sufficient

airflow )

• Clean the motor fan cover.

• Clean the motor fan blade.

Do NOT operate the machine with damaged or

removed fan cover.

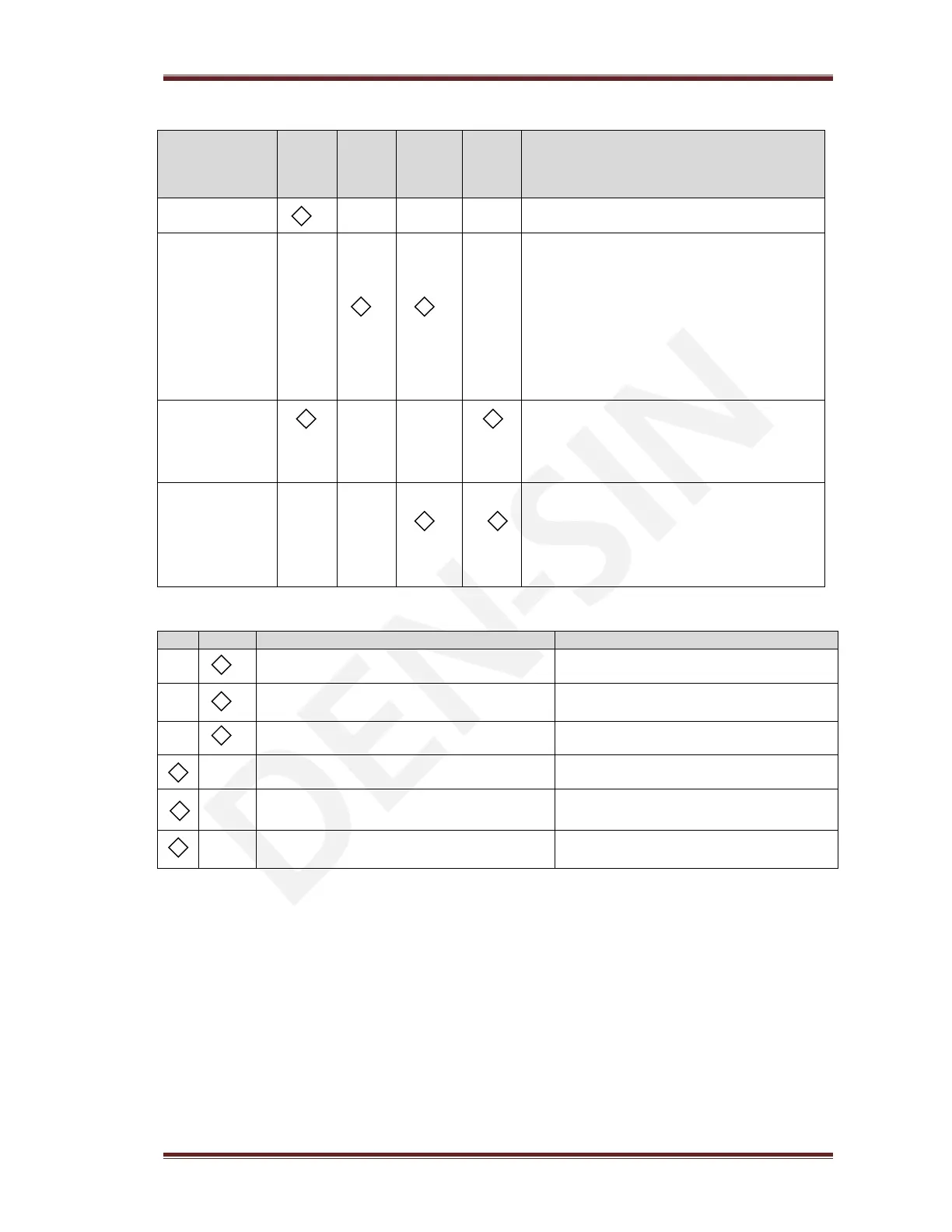

Machine Prevention

Spray directly onto the machine with high

Electrical shock may occurs

Operate the machine with damaged or removed

fan cover

Motor will be overheated and malfunction

Operate/keep machine with frost built up

Flush pump with antifreeze fluids before use.

Check hose and cord are not vehicle run over

May cause machine not function properly.

Check electrical cord and high pressure hose

for wear and cracks

To prevent electrical shock and safety to the user

Ensure coupling parts free of dirt to ensure

long life of O-ring seals preventing water leaks.

Extend life span of the pump seals and

maintaining correct pressure.

Loading...

Loading...