15

FT Range SP20001_REV_2

General Lubrication

REAR ROLLER

The centre section gear case chamber of the rear roller is an assembly in two halves and contains the epicyclic gear

system, which runs in an oil bath.

The chamber is charged with gear oil EP 90 before the machine leaves the works and should require no further fi lling

during the cutting season. If in every day use then a topping up charge of about one egg cup full every two months may

be appropriate.

DO NOT OVERCHARGE. AT NO TIME SHOULD THERE BE MORE THAN 100CC OF OIL

IN THE CHAMBER.

WARNING

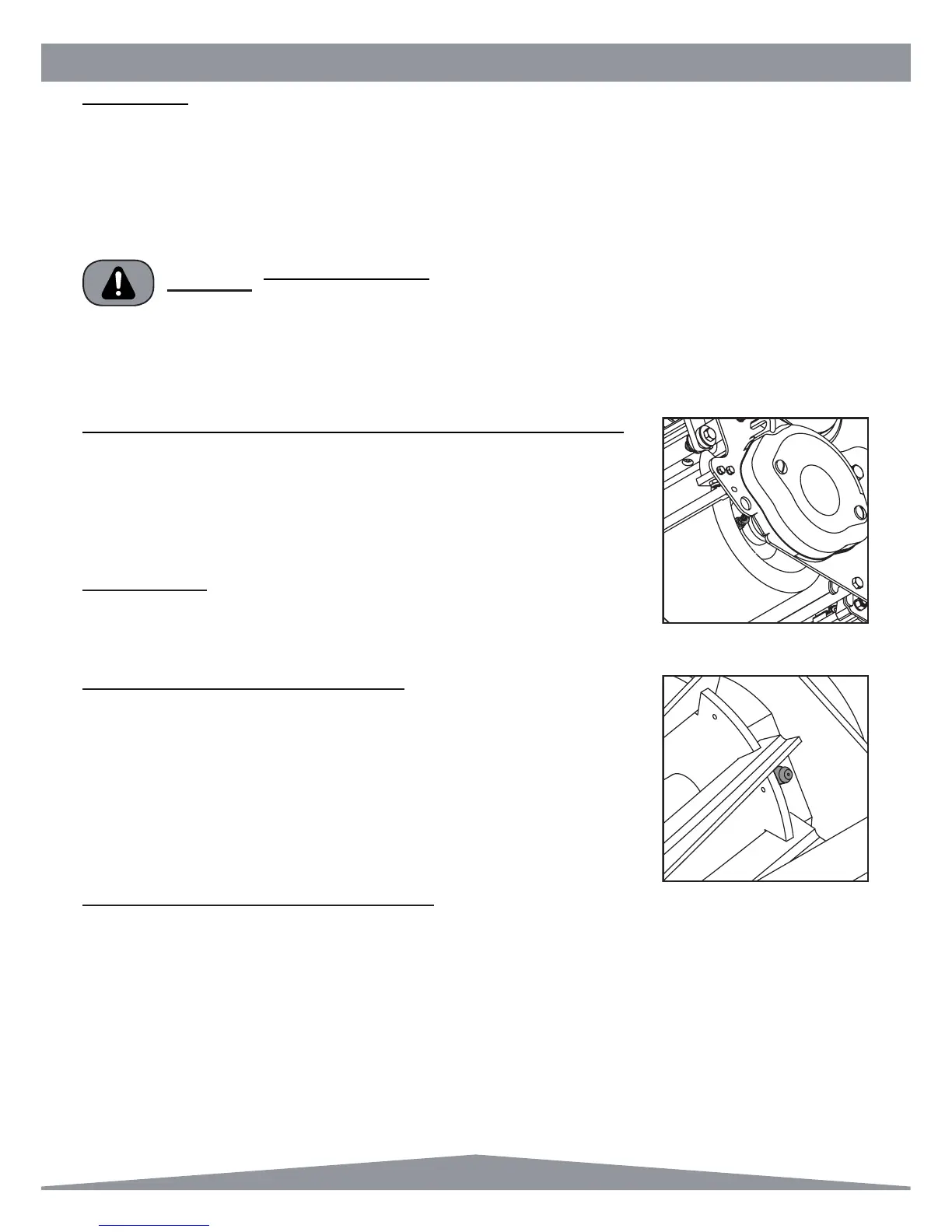

Access to the chamber is gained by unscrewing the hexagon screw found in the recess of the centre section of roller.

Clean away all dirt and grit before removing this screw. On replacing the screw, make sure it is tight and secure.

Recommended grade gearbox oil EP90.

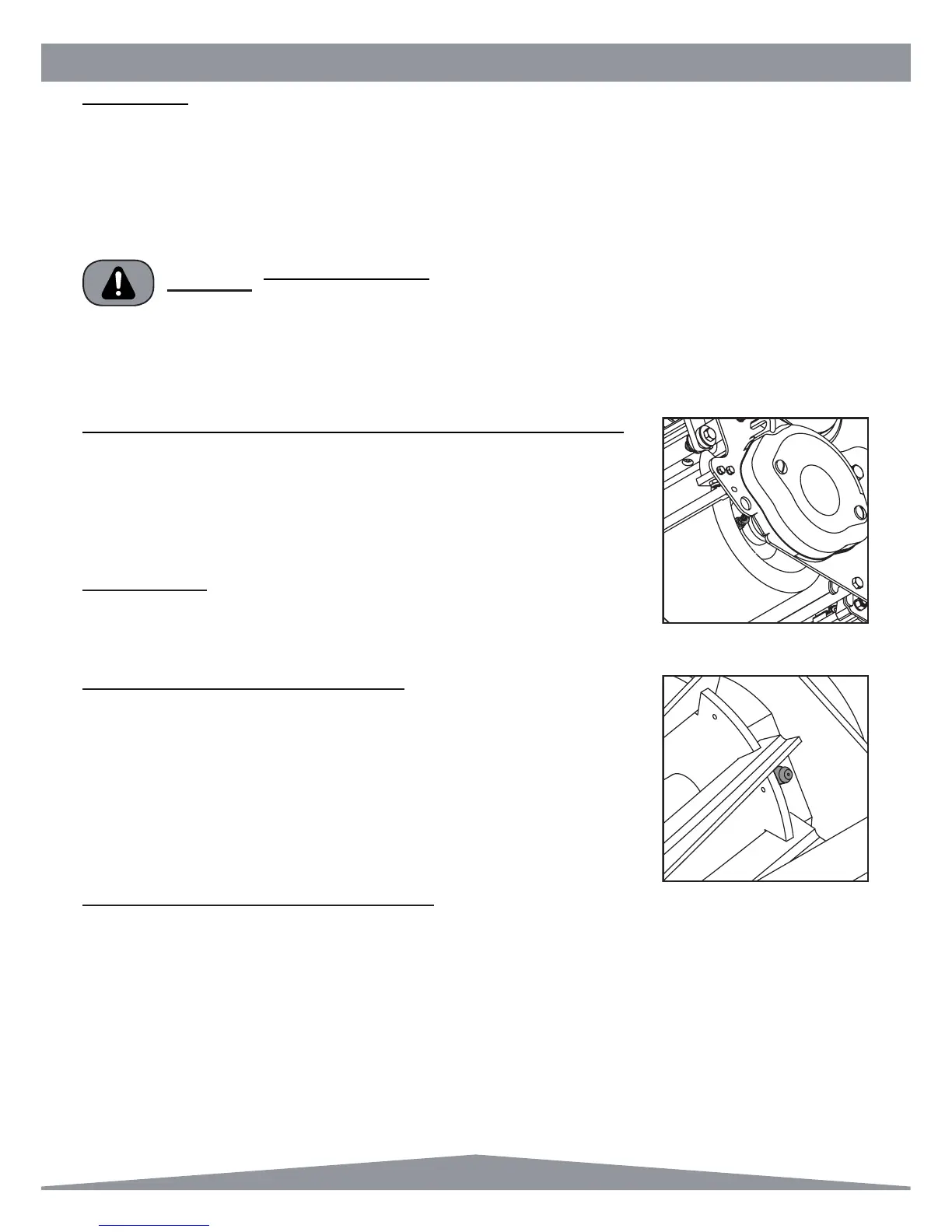

RATCHET PAWLS AND DRUM HUBS OF THE REAR ROLLER (Every 2 Months)

Projecting from the side face towards the centre of each outer drum will be seen two

grease nipples which provide access for lubrication to the rear roller driving pawls and

the drum hub bearing sleeve.

A small charge of light grease should be applied every two months.

FRONT ROLLERS

The bearings used on the front rollers are pre packed with grease and rubber shielded,

therefore requiring no additional greasing.

CYLINDER CASSETTE BEARINGS (Every Day)

To apply lubrication to the cylinder cassette bearings it is fi rst necessary to remove the

cassette unit from the chassis as described on page 9.

Projecting from each bearing cover will be seen a grease nipple through which a small

charge of grease should be applied using the grease gun

MEDIUM GREASE = GOOD QUALITY

SCARIFIER / DE-THATCHER / BRUSH CASSETTES

No grease or oiling is required.

Loading...

Loading...