NOTE

Record all faults on the Fault Record Sheet

supplied at the back of this manual.

ROUTINE MAINTENANCE

The Model 505 Transmitter requires no routine

maintenance, except for periodic checks to ensure

proper calibration. The frequency of these checks is

determined by the requirements of the particular

installation. Calibration gas kits are required for these

checks.

CHECKOUT IN NORMAL MODE

The entire gas detection system should be checked

periodically to ensure that the presence of gas at the

sensor will result in the proper system response.

SENSOR INSPECTION

Since a dirty or plugged sensor filter can adversely

affect the response time of the sensor by restricting the

flow of gas to the sensing element, it should be

inspected on a regular basis. If a dust cover or splash

shield is used, it should also be checked.

SENSOR SENSITIVITY

If sensor response to 50% LFL methane is less than 15

millivolts, the sensor should be replaced. Refer to Table

2, “Calibration Procedure” for information regarding

calibration and sensor sensitivity.

SENSOR REPLACEMENT

De-classify the area prior to replacing the sensor and

secure any output devices connected to the system to

prevent unwanted actuation of this equipment. To

replace the sensor:

1. Verify that no hazardous levels of combustible gas

are present at the sensor, then remove the cover

from the junction box.

2. Unplug the sensor from the circuit board and

unscrew it from the junction box.

3. Coat the threads of the new sensor with silicone

free grease, then screw the sensor into the junction

box and plug it into the circuit board.

4. Allow the sensor output to stabilize under power

(about two hours minimum for best results), then

13 95-8472

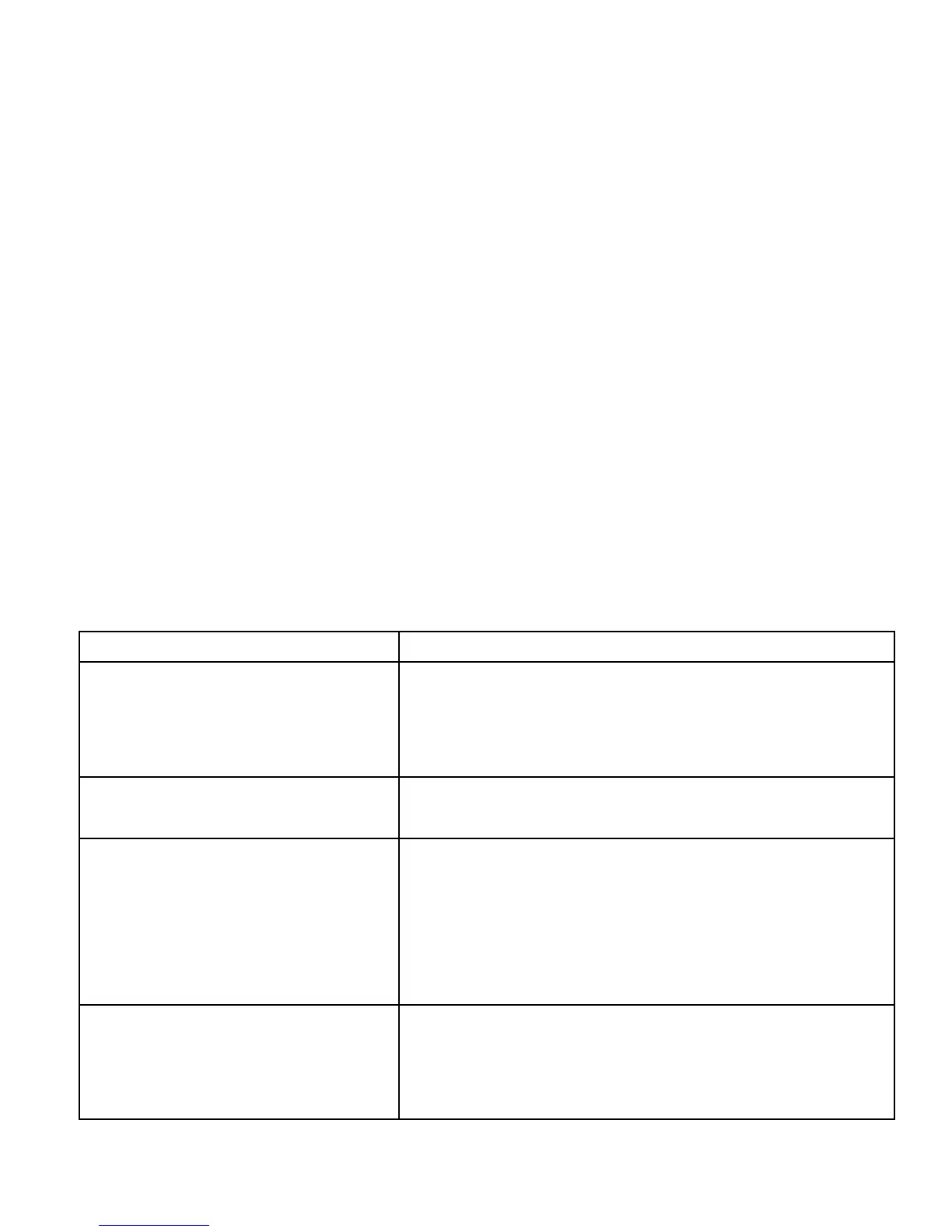

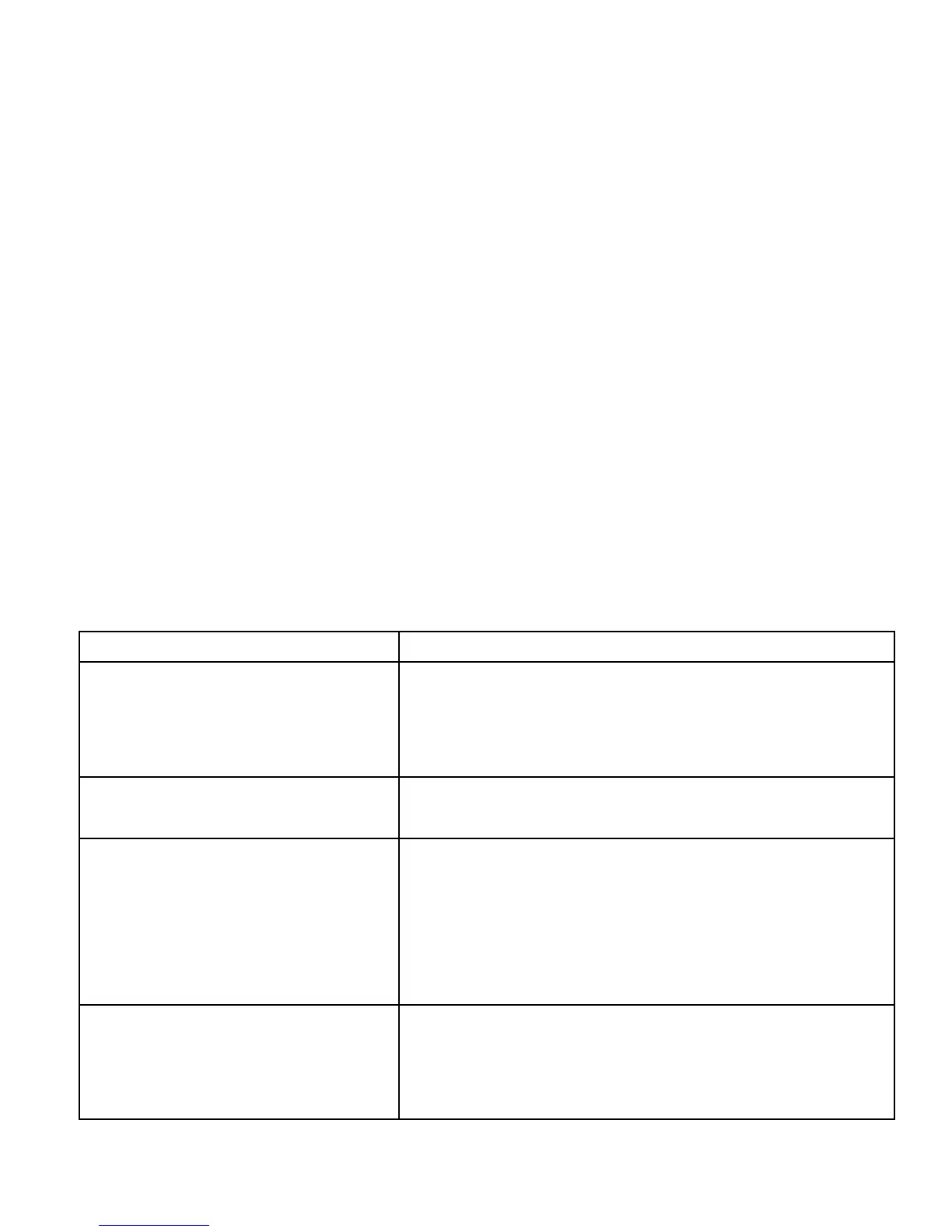

SYMPTOM POSSIBLE CAUSE

Controller display shows full scale reading Over 100% LFL gas at sensor. Take appropriate safety measures.

Transmitter not calibrated.

Defective sensor.

Power (+) shorted to signal.

No output from transmitter. Power supply failure.

Power or signal wiring problem.

Negative % LFL display at controller. No power to transmitter.

Transmitter not calibrated.

Sensor not connected.

Defective sensor.

SIG wire problem.

CAL/NORM switch in CAL position.

Signal level at controller different than at transmitter. Loose wiring connection.

Total signal wiring loop impedence too high.

Induced EMI/RFI interference from nearby EMI fields (motors, switches, etc.).

Improper earth ground connection of signal wire shield.

Table 3—

Troubleshooting Guide

Loading...

Loading...