Section II —

Description

and Operating Characteristics

DESCRIPTION

The Model 505 Transmitter is used with one constant

voltage catalytic gas sensor to provide a linear 4 to 20

ma output signal corresponding to a 0 to 100% LFL gas

concentration (see Figure 4). Intrusive calibration and

sensor sensitivity check are performed using a standard

digital voltmeter (not provided). An explosion-proof

junction box with removable cover is included with all

Model 505 Transmitters. Options include junction box

material (aluminum or stainless steel), number of

conduit entry ports (up to five), conduit entry threads

(NPT or Metric), orientation of entries (180 degree

straight-through or 90 degree “L”), and signal output

load impedance (125 or 500 ohms). The Model 505

with signal loop impedance option “A” directly replaces

the Det-Tronics K-Series Transmitter (125 ohms) and the

Model 505 with signal loop impedance option “B”

replaces the Det-Tronics Model 500 Transmitter (500

ohms).

SENSOR

Det-Tronics constant voltage catalytic bead type

combustible gas sensors are used with the Model 505

transmitter family.

GENERAL APPLICATION

INFORMATION

A combustible vapor or gas is one that will burn when

mixed with air (or oxygen) and ignited. Every vapor has a

minimum and maximum concentration in air, which

together form the “flammable” or “explosive” range. The

lower explosive limit (LEL) or lower flammable limit (LFL)

is defined as the smallest amount of the gas that will

support a self-propagating flame when mixed with air (or

oxygen) and ignited. The range of gas concentration

measurement for most catalytic sensor-based gas

detection systems, including the Model 505 transmitter, is

0 to 100% LFL, with 0% LFL being a gas-free atmosphere

and 100% LFL equaling the gas concentration at its lower

flammable limit. The relationship between % LFL and %

by volume differs from gas to gas. ASTM E681 is the

existing standard method for determining flammable

limits. Examples include:

Hydrogen (H

2

), 100% LFL = 4.0% by volume in air

Methane (CH

4

), 100% LFL = 5.0% by volume in air

Ethane (C

2

H

6

), 100% LFL = 3.0% by volume in air

Ethylene (C

2

H

4

), 100% LFL = 2.7% by volume in air

Pentane (C

5

H

12

), 100% LFL = 1.5% by volume in air

Propane (C

3

H

8

), 100% LFL = 2.2% by volume in air

For data on other gases, refer to NFPA Handbook

325M.

Typical alarm setpoints for combustible gas detection

systems are 20% LFL for the low alarm and 40% LFL for

the high alarm.

The LFL of a gas is affected by temperature and

pressure. As the temperature increases, the LFL

concentration decreases, and the explosion hazard

increases. The relationship between LFL and pressure

is fairly complex, however, a pressure increase usually

lowers the LFL. The LFL of a gas is not significantly

affected by the humidity fluctuations normally

encountered in typical industrial applications.

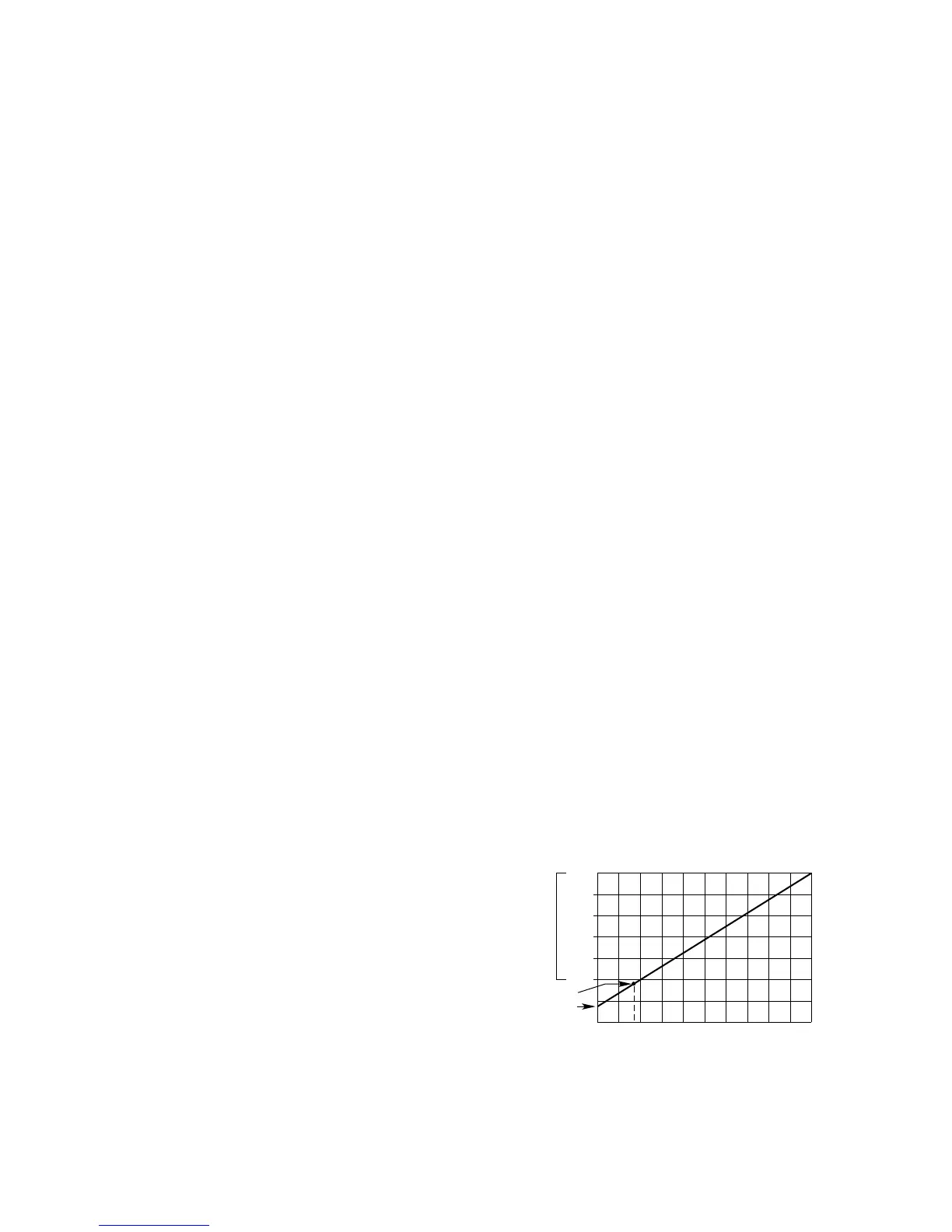

SENSOR RESPONSE

Figure 5 shows the typical response of a catalytic gas

sensor to various levels of methane. Note that a reading

of 40% LFL will be given at 2.0% by volume methane

and also at 80.0% by volume methane, which is well

above the upper flammable limit. Although gas

concentrations above the upper flammable limit will not

propagate a flame, it is likely that somewhere in the

protected area there may be a flammable

concentration.

All catalytic sensors require oxygen to accurately

measure combustible gas concentrations. Sensor

response and accuracy will decrease when the oxygen

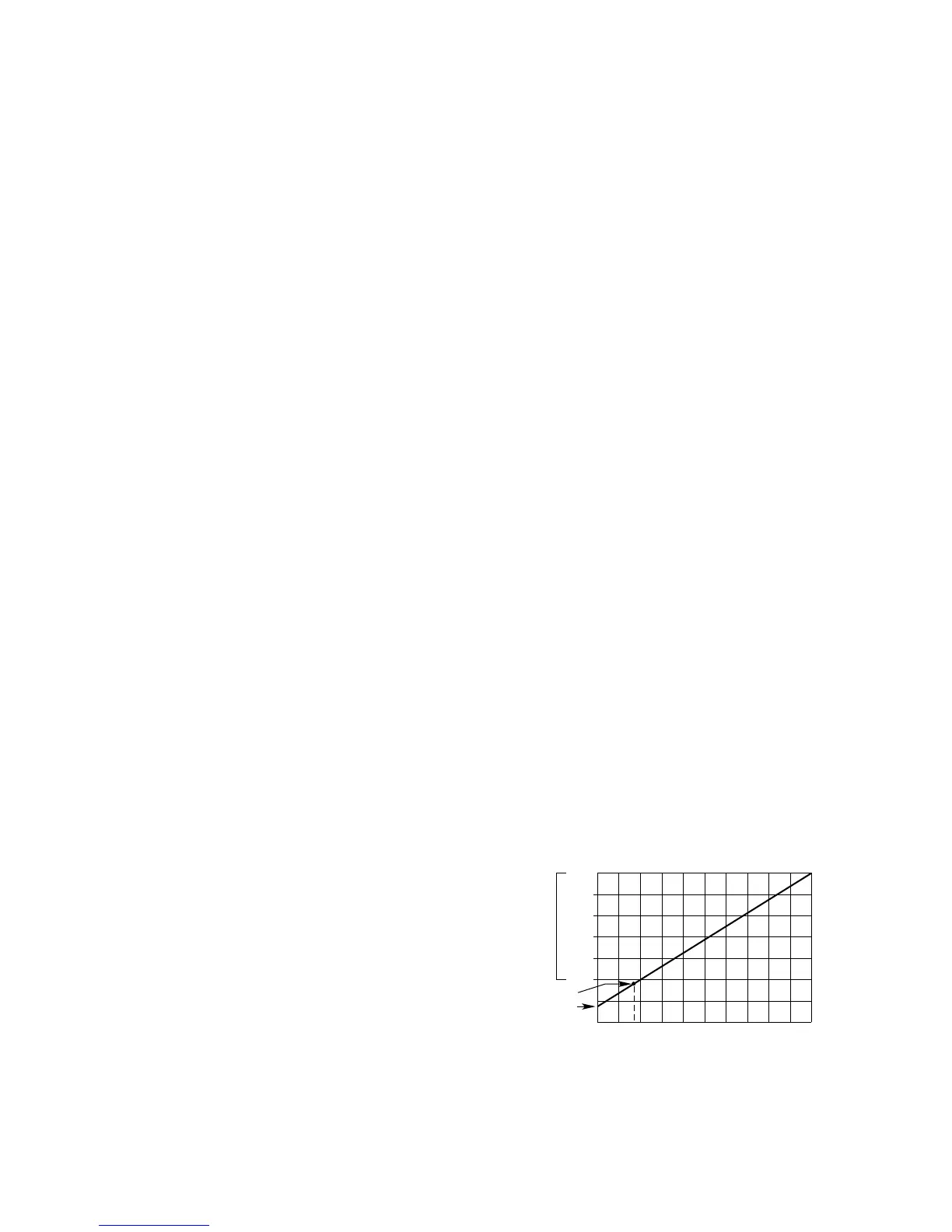

level is less than 10%. Figure 6 shows the effect of

oxygen enriched and oxygen deficient atmospheres on

the response of a typical catalytic gas sensor. Do not

use catalytic gas sensors in areas where the oxygen

level is less than 10% by volume.

Loading...

Loading...