700 RAM I.M.

700 RAM I.M. Rev. 1.1 Page 5 of 12

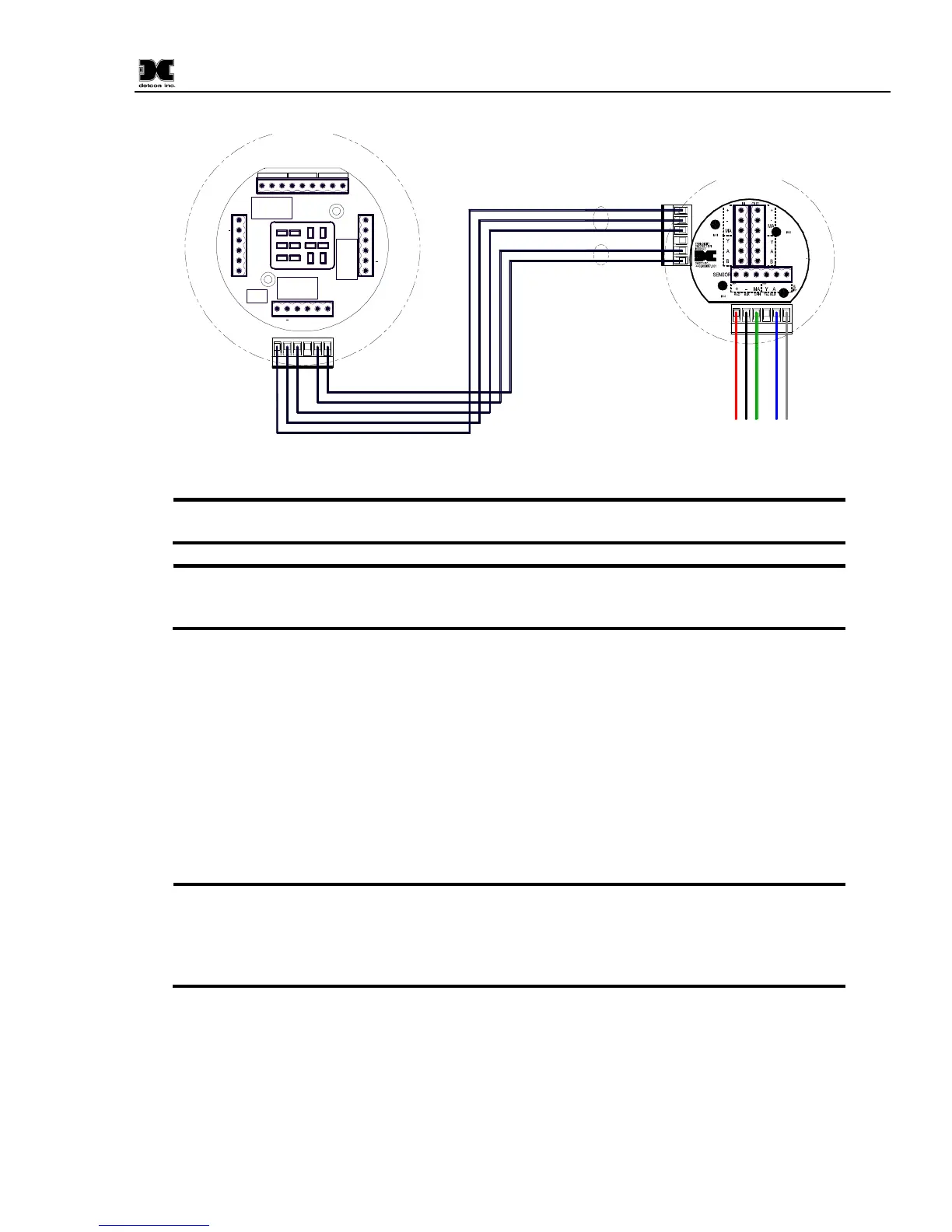

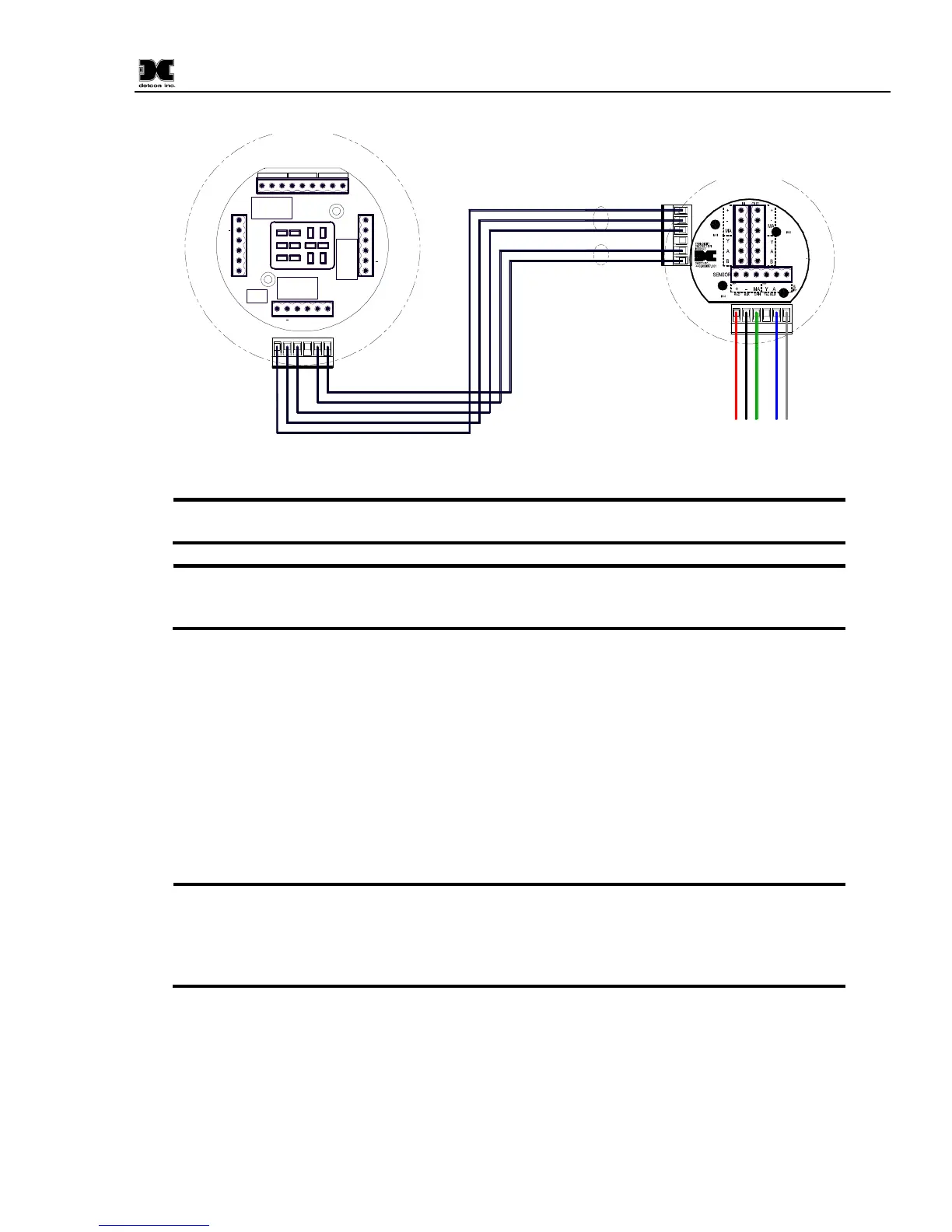

(+)

mA

(-)

A(+)

B(-)

Wiring to

Sensor Assembly

Wht

Blu

Red

Grn

Blk

Remote

Explosion Proof

Junction Box

with Sensor

(+)

mA

(-)

A(+)

B(-)

Customer

Supplied Wiring

Transient Protection Module

(TPM) P/N 500-003087-100

Modbus RS-485 to

Host Control Device

Power from and 4-20mA

out to Control Device

ALM1ALM2 FLT

NO NC COM NO NC COM NO NC COM

J7

J2

J1

J4

IN

SENSOR

OUT

+

+

mA

A B

mA

A

B +

A

B

K1

K3

K2

Explosion Proof

Junction Box

with RAM Module

(+)

mA

(-)

A(+)

B(-)

Figure 8 Remote Sensor Wiring

Both the 3-wire power/mA cable and the 2-wire Modbus™ serial communications

cable are required when remote wiring between the RAM and the 700 Gas Sensor.

The same recommended cables should be used for the connection between a

Modbus™ master control device and the RAM. However, if only the 4-20mA signal is being

used by the master/host controller, then only the 3-wire cable is required.

2. Operator Interface

The operator interface of the RAM is very similar to the Model 700 Gas Sensor. It uses the identical LED

display, same programming magnet, and has the same magnetic programming switches (PGM1/ZERO and

PGM2/SPAN). The main difference is that the 700 RAM has LED indicators for the 3 relays (ALM1,

ALM2 and FAULT) and a CAL LED to indicate when the 700 sensor is in calibration or being polled

serially by a master control device.

The gas reading, gas units, and fault status reported by the RAM will mimic that of the 700 Gas Sensor. The

Modbus™ output from the RAM repeats the Modbus™ output from the 700 Gas Sensor.

If the Model 700 Gas Sensor is directly connected to the RAM and junction box, then

the gas sensor operation should be exercised through the 700 Gas Sensor (and not the RAM).

This is the recommended practice since the RAM contains a limited number of sensor

operational control functions. If the RAM and 700 Gas Sensor are separated, then normal

remote gas sensor operation should be exercised through the RAM.

The operating interface is menu-driven via the two magnetic program switches located under the target

marks on the RAM faceplate. The two switches are referred to as “PGM1” and “PGM2”. The menu list

consists of three major items that include sub-menus as indicated below. (Refer to the complete Software

Flow Chart Figure 9)

Normal Operation

Current Reading and Fault Status

Loading...

Loading...