14

Troubleshooting Possible Problems in Operation

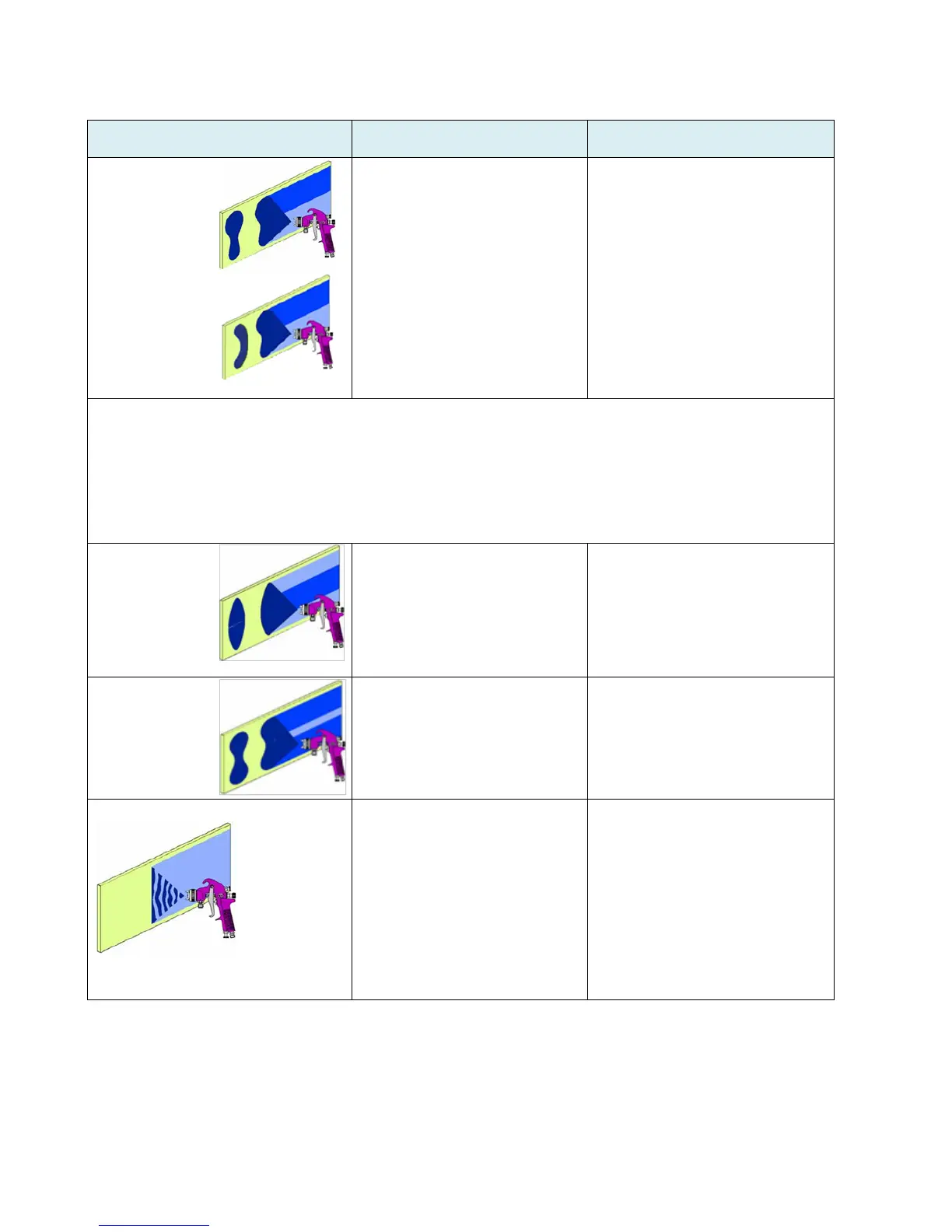

CONDITION CAUSE CORRECTION

Heavy top

or

bottom pattern

Heavy right

or

left side pattern

Horn holes plugged.

Obstruction on top or bottom of

fluid nozzle.

Cap and/or nozzle seat dirty.

Left or right side horn holes

plugged.

Dirt on left or right side of fluid

nozzle.

Clean. Ream with non-metallic

point.

Clean.

Clean.

Clean. Ream with non-

metallicpoint.

Clean.

Remedies for the top-heavy, bottom-heavy, right-heavy, and left-heavy patterns:

1. Determine if the obstruction is on the air cap or the fluid nozzle. Do this by making a test spray pattern. Then,

rotate the cap one-half turn and spray another pattern. If the defect is inverted, obstruction is on the air cap.

Clean the air cap as previously instructed. Also check for dried paint just inside the cap centre hole opening;

remove by washing with solvent.

2. If the defect is not inverted, it is on the fluid nozzle. Clean nozzle. If problem persists, renew nozzle.

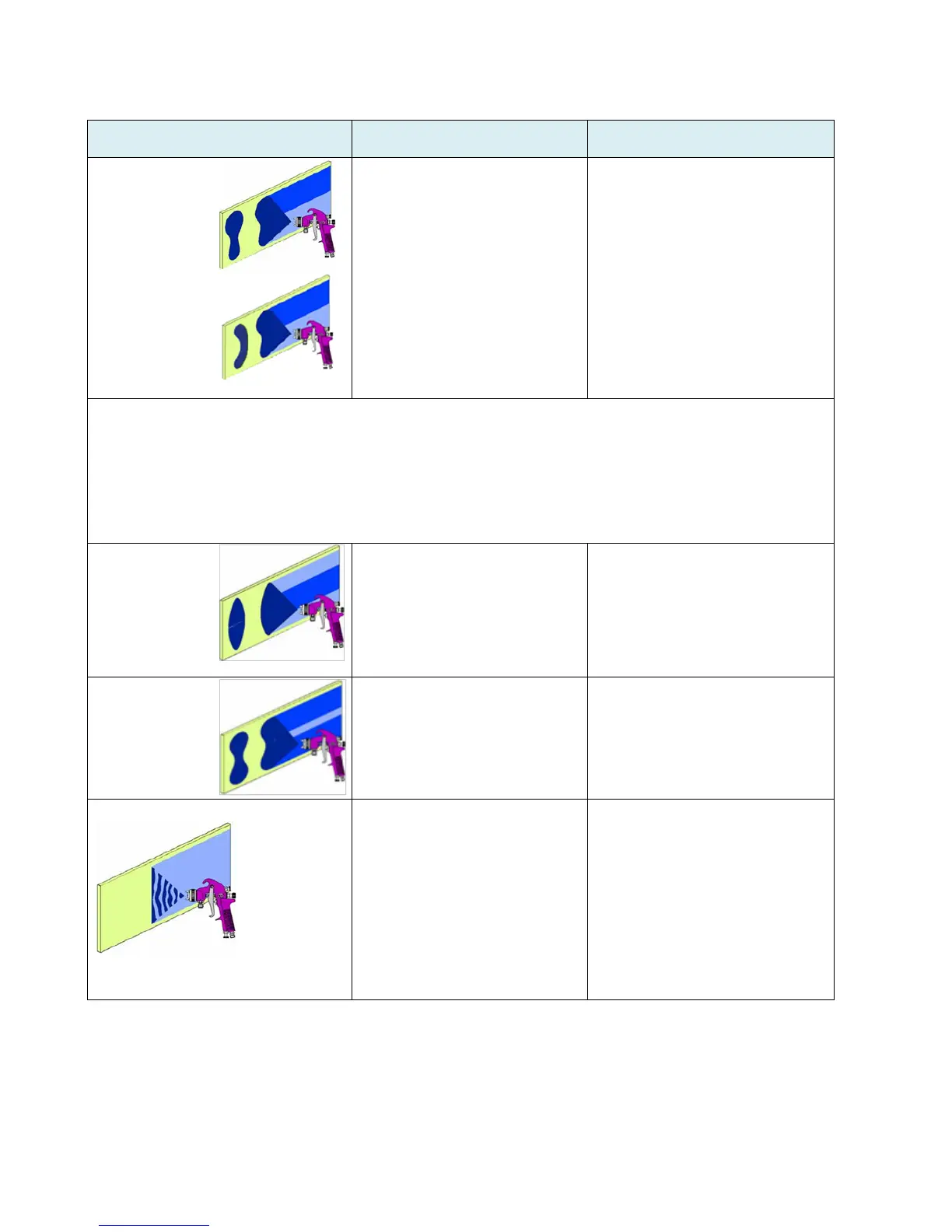

Heavy centre

pattern

Spreader adjustment valve set

too low.

Atomising pressure too low.

Material too thick.

Turn out counter clockwise to

achieve correct pattern.

Increase pressure.

Thin to correct consistency

Air pressure too high.

Fluid adjusting knob turned in too

far.

Spreader adjusting valve set too

Reduce at regulator or gun handle.

Turn out counter clockwise to

achieve correct pattern.

Turn in clockwise to achieve

Jerky or fluttering spray

Loose or damaged fluid

nozzle/seat

Loose or broken cup fluid nipple

Material level too low

Container tipped too far

Obstruction in fluid passage

Loose fluid needle packing nut

Damaged fluid needle packing

Tighten or replace

Tighten or replace cup

Refill

Hold more upright

Back flush with solvent

Tighten

Replace

Loading...

Loading...