ENGLISH

6

Carrying the Chop Saw (Fig. A)

Fold down unit to position where you can carry the saw.

Push in lock pin

1

to lock armdown. Always carry the saw

using the carrying handle

18

.

Unlocking (Fig. A)

To unlock tool and raise head, depress motor arm slightly

and pull lock pin

1

out. Motor arm will then pivotupward.

Mounting (Fig. A)

CAUTION: Tool must be supported on stable, level,

non-skid surface to prevent unexpected movement

whenoperating.

1. Drill holes through the work surface that align the base

of the chopsaw.

2. Insert two 5/16" (M10) bolts down through the

mounting holes

16

in the base and through holes

in mounting surface. The approximate length of the

screws should be the thickness of the mounting surface

plus 4" (102mm).

Spark Deflector Adjustment (Fig. A)

WARNING: Do not touch the spark deflector

during or immediately after operation as it

becomes hot and may cause skin burn.

To best deflect sparks away from surrounding persons and

materials, loosen the spark deflector screw

2

, adjust the

spark deflector

3

and then retighten screw. Do not allow

cordset to come into contact with deflector or sparks as

damage to cordset mayoccur.

Lock-Off Trigger Switch (Fig. A)

To turn the saw on, push the lock-off lever

14

to the left,

then depress the lock-off trigger switch

13

. The saw will

run while the switch is depressed. Allow the blade to spin

up to full operating speed before making the cut. To turn

the saw off, release the switch. Keep hands and material

away from the wheel until it has coasted to a stop. Allow

the blade to stop before raising the saw head. There is no

provision for locking the switchon.

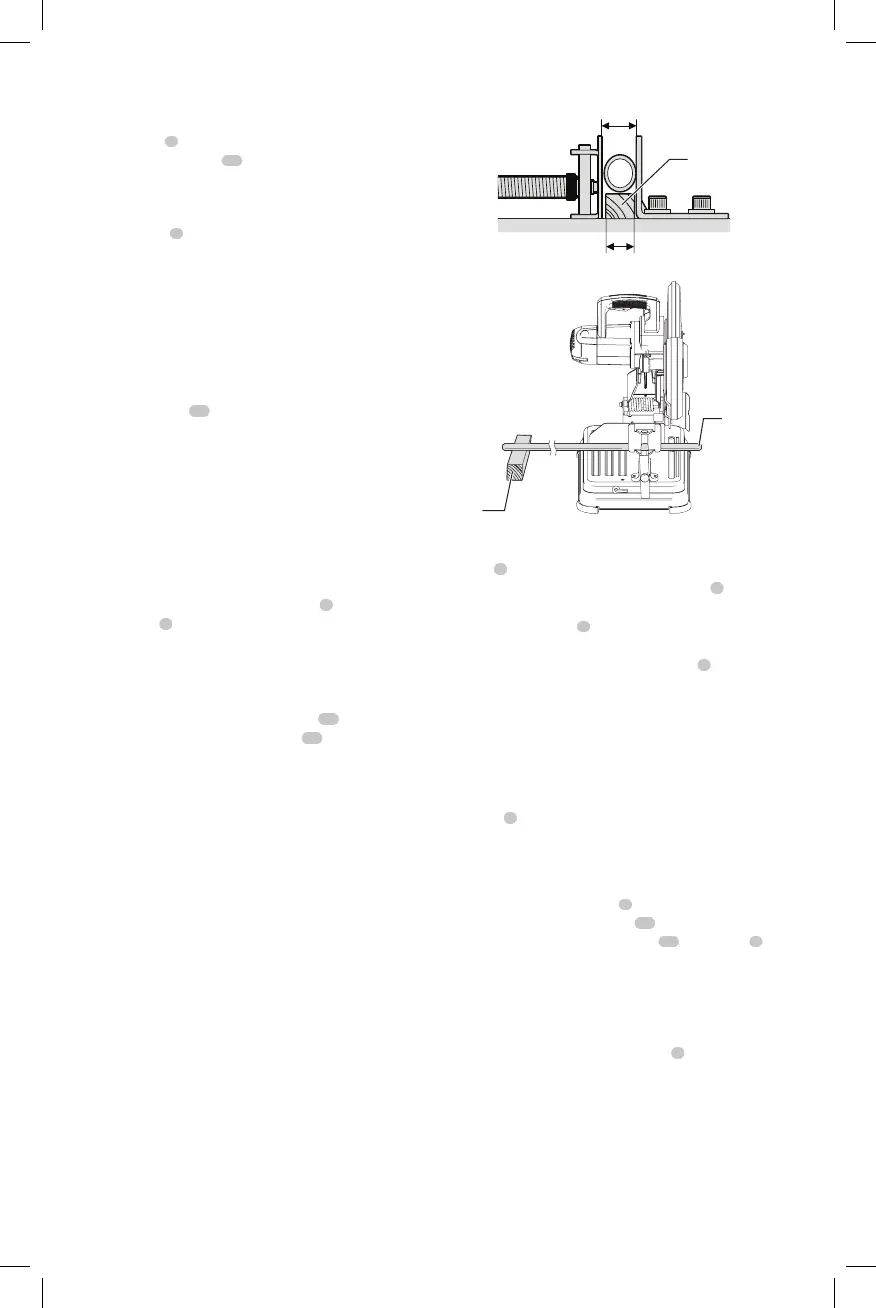

Material Clamping and Supporting

(Fig. C, D)

• Angles are best clamped and cut with both legs resting

againstbase.

• A spacer block slightly narrower than the workpiece can

be used to increase wheel utilization (Fig.C).

• Long workpieces must be supported by a block so it will

be level with top of base (Fig. D). The cut off end should

be free to fall downward to avoid wheelbinding.

Diameter of workpiece

Fig. C

Width of space block

Space block

Fig. D

Block

Cut-off end

Vise Operation (Fig. A)

The vise

6

has a quick-travel feature. To release the

vise when it is clamped tightly, turn the crank

8

counterclockwise one or two times to remove clamping

pressure. Lift vise lever

9

up. Pull crank assembly out as far

as desired. Vise may be pushed forward into work without

cranking. Lower vise lever then tighten vise

6

on work by

usingcrank.

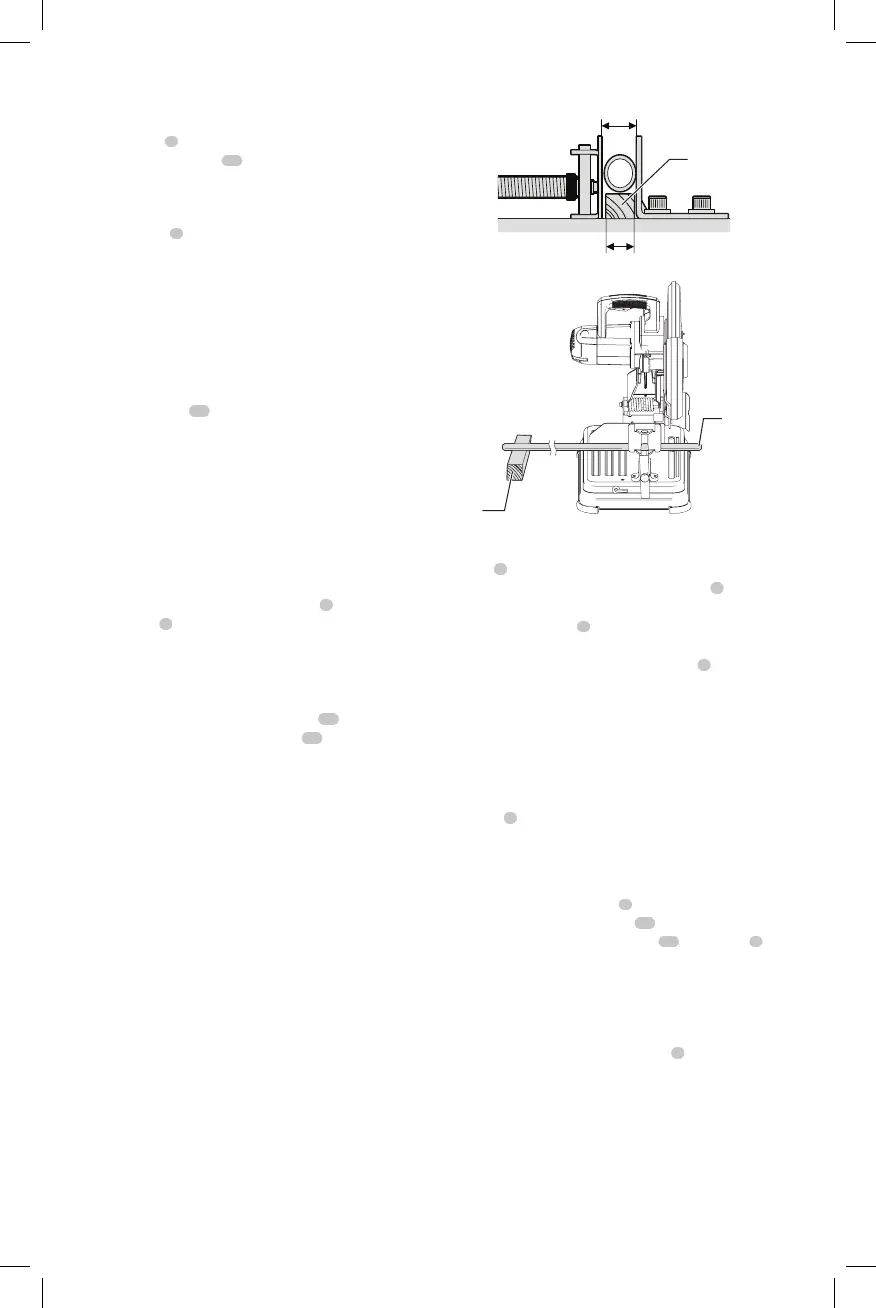

Fence Operation (Fig. A, E, F)

WARNING: Turn off and unplug the tool before

making any adjustments or removing or

installing attachments or accessories. Be sure the

trigger switch is in the OFFposition.

The fence

5

can be adjusted two ways: to change desired

cutting angle and to change spacing between the fence

andvise.

To Change the Desired Cutting Angle

Use the 5/16" (8mm) hex key

7

provided to loosen (do

not remove) the two fence bolts

15

. Align the desired

angle indicator line with the slot line

26

in the base

4

.

Securely tighten both fence bolts before use. For more

accurate square cuts, disconnect the power supply, loosen

the two fence bolts, push arm down until wheel extends

into base. Place a square against the wheel and adjust fence

against the square. Securely tighten both fence bolts before

use. When making a miter cut, the vise

6

may not clamp

securely, depending on the thickness of the workpiece and

the miter angle. Other aids (such as spring, bar or C-clamps)

will be necessary to secure the workpiece to the fence when

making thesecuts.

Loading...

Loading...