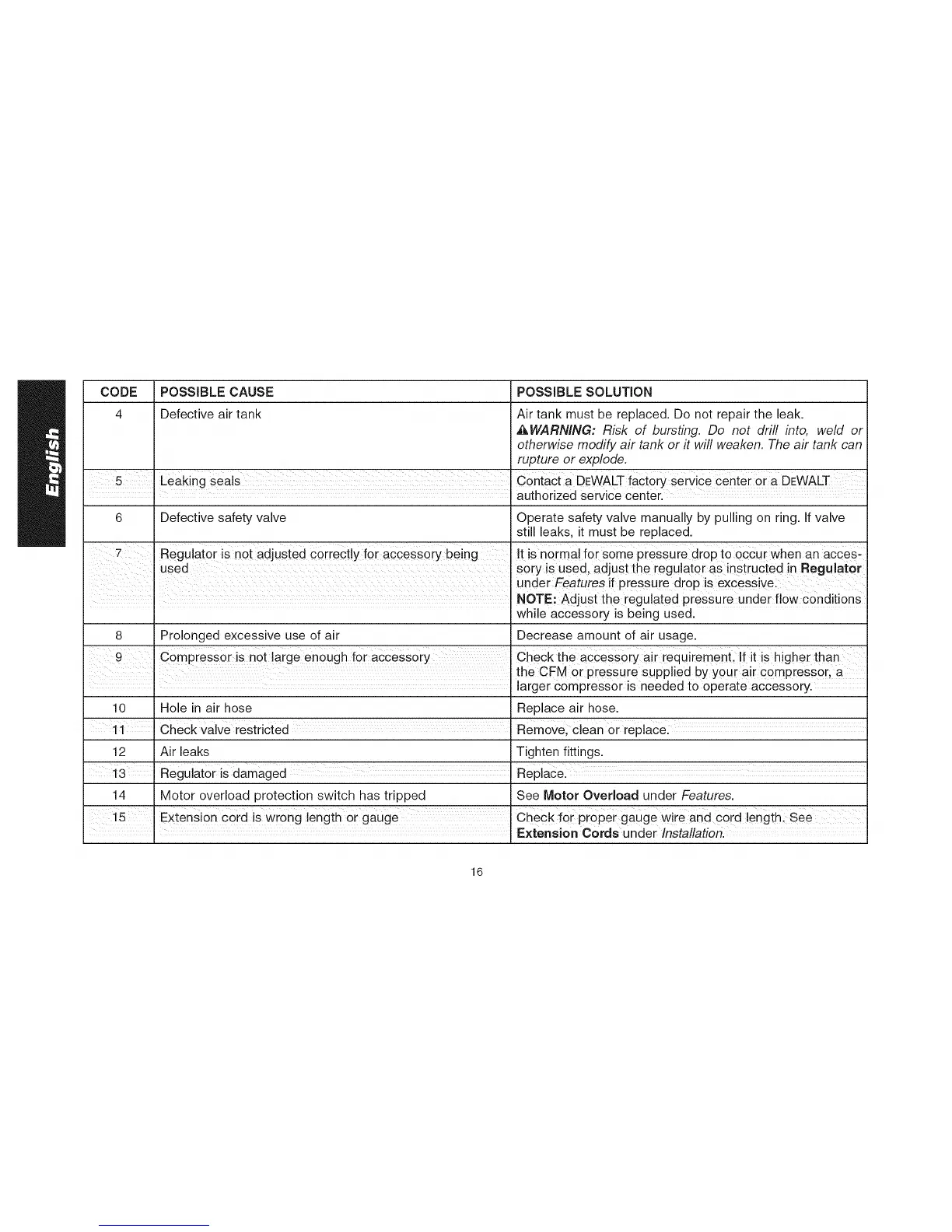

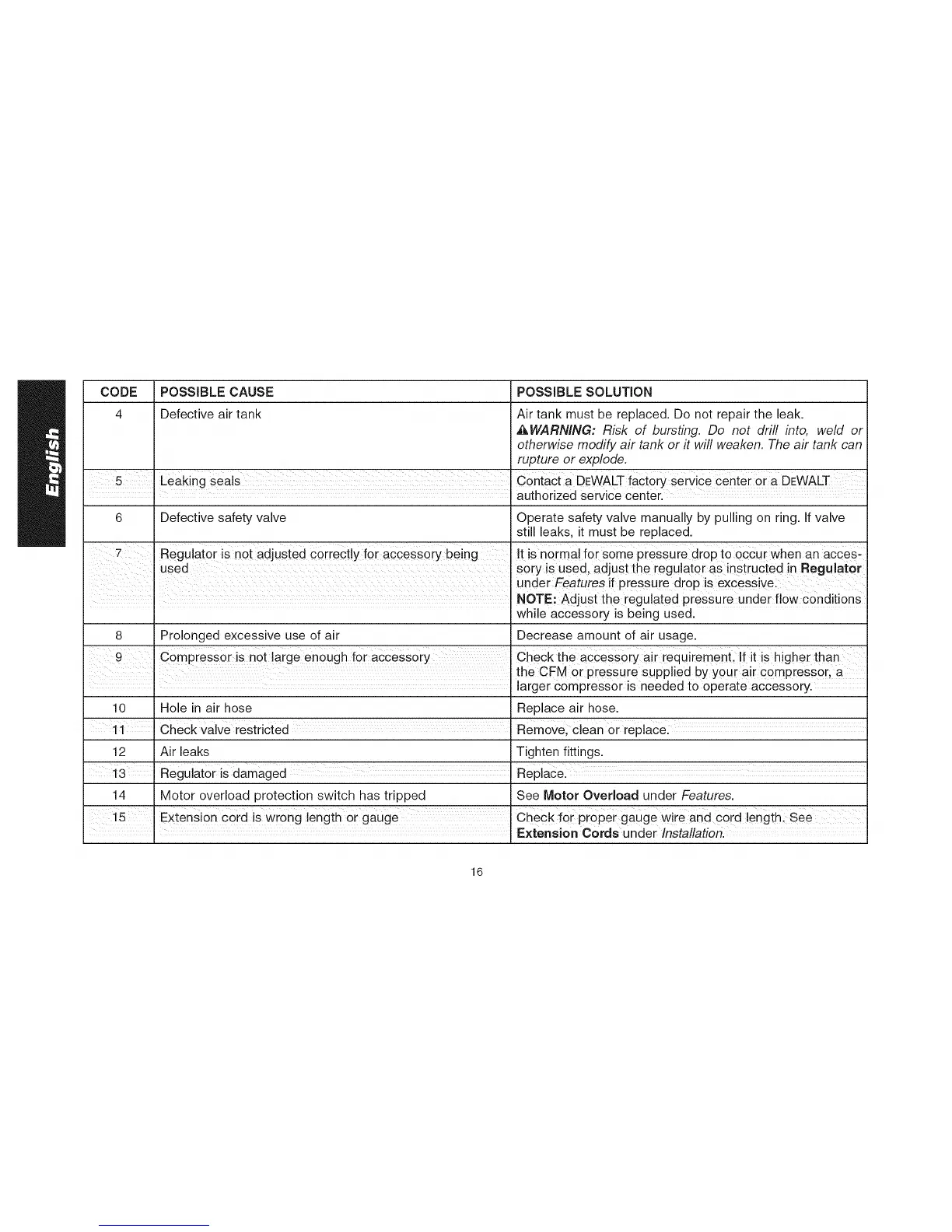

CODE POSSIBLE CAUSE POSSIBLE SOLUTION

4 Defective air tank Air tank must be replaced. Do not repair the leak.

_WARNING: Risk of bursting. Do not drill into, weld or

otherwise modify air tank or it will weaken. The air tank can

rupture or explode.

5 Leaking seals Contact a DEWALT fact0ry Service center or a DEWALT

author zed serv ce center.

6 Defective safety valve Operate safety valve manually by pulling on ring. If valve

still leaks, it must be replaced.

7 Regulator iS not adjusted correctly for accesSory being it is n0rmal for Some pressuie drop to 0CCurWhen an acCes_

use_d sory is used, adjust the iegulat0r as instiucted n RegulatOr

i uncierFeatures f pressure drop s excessve:

! NOTE:AdJust the regulated pressure under flow conditions

while accessory is being used.

8 Prolonged excessive use of air Decrease amount of air usage.

'Compressor isnot !arge enough for accessory Check the aCceSS0iY air requiremenL if it is higher than

I the CFM or pressure supplied by your air €0mpressor, a

. larger compressor is needed to operate accessory.

10 Hole in air hose Replace air hose.

11 Check valve restricted Remove; clean or replacel

12 Air leaks Tighten fittings.

13

14 Motor overload protection switch has tripped See Motor Overload under Features.

I

15 , Extension cord is wrong length or gauge Check for proper gauge wire and cord length. See

Extension Oords under lnstallationl

16

Loading...

Loading...