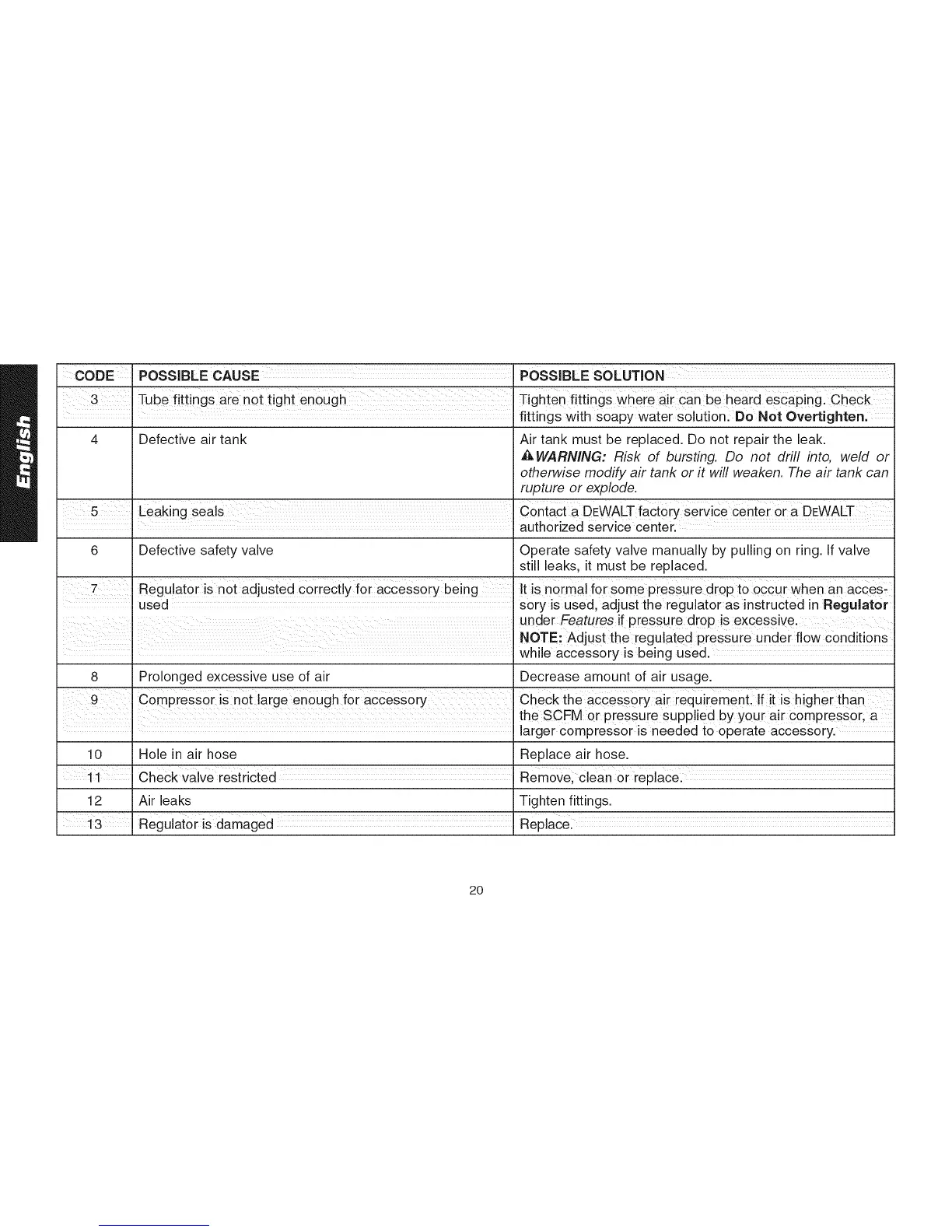

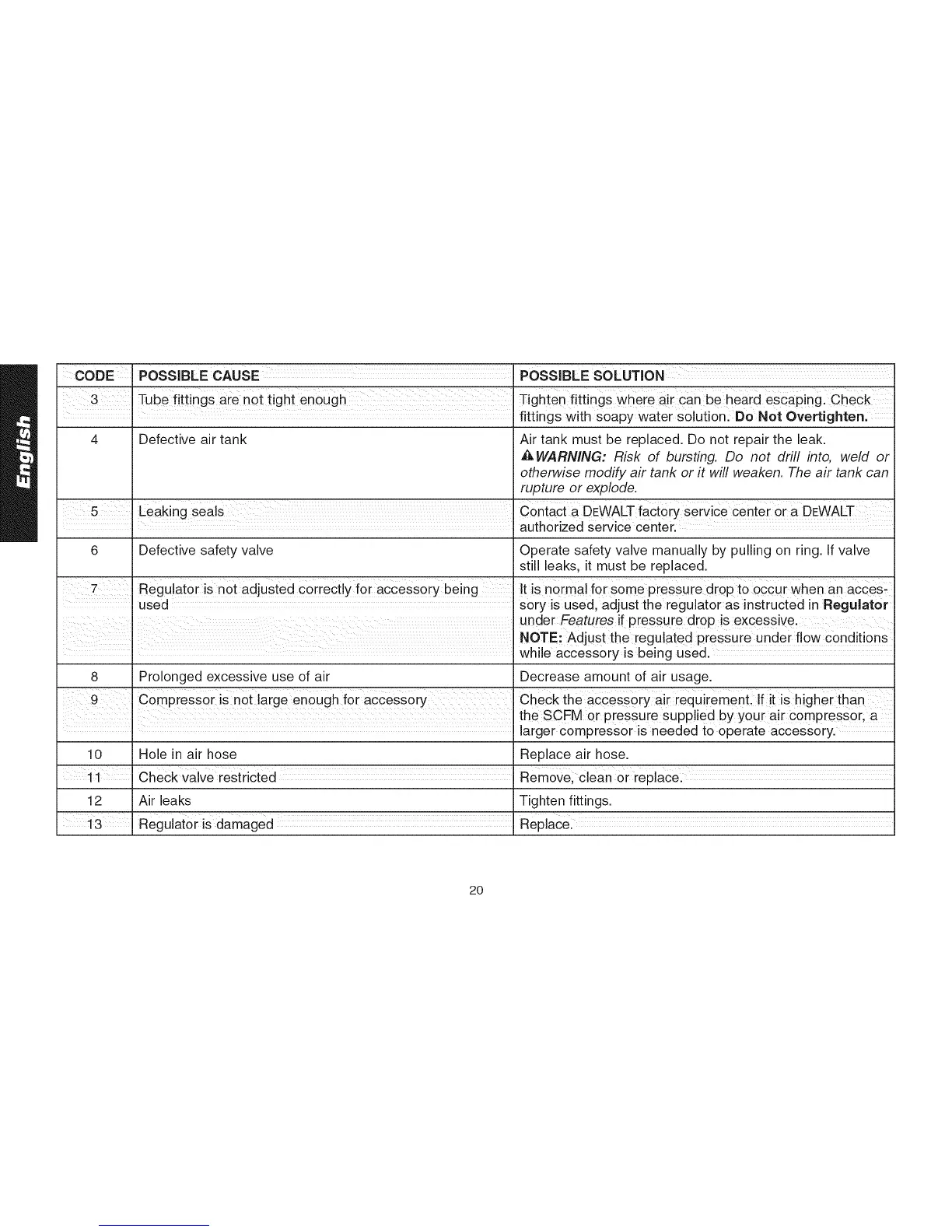

CODE POSSIBLE CAUSE POSSIBLE SOLUTION

3 Tube fittings are not tight enough Tighten fittings Where air Can be heard eScaPingl cheCk

• fittings with soapy water solution. Do Not Overtighten.

4 Defective air tank Air tank must be replaced. Do not repair the leak.

&WARNING: Risk of bursting. Do not drill into, weld or

otherwise modify air tank or it will weaken. The air tank can

rupture or explode.

contact a DEWALT factory service cente[ 0r a DEWALT

• authorized Service center.

6 Defective safety valve Operate safety valve manually by pulling on ring. If valve

still leaks, it must be replaced.

Regulator is not adjusted coirect!y foi access0iY being, !t is norma! for some pressure drop to occur when an acceS'

used .............................. sory is used, adjust the regulator as instructed in Regulator

under Features if pressure drop s excessive.

, NOTE: Adjust the iegulated pressure undei fl0w cond!tionS

wh e accessory s be ng used.

8 Prolonged excessive use of air Decrease amount of air usage.

compressoi is n0t laige en0ugh f0i acceSSorY Check the accessory air reqUiremenL If it is higher than

the SCFM or pressure Supp!ied by your air Compress0r, a

larger compressor is needed to operate accessory.

10 Hole in air hose Replace air hose.

11 ' Check valve restricted Remove; Clean or replace.

12 Air leaks Tighten fittings.

13 Regulator is damaged Replace:

2O

Loading...

Loading...