16

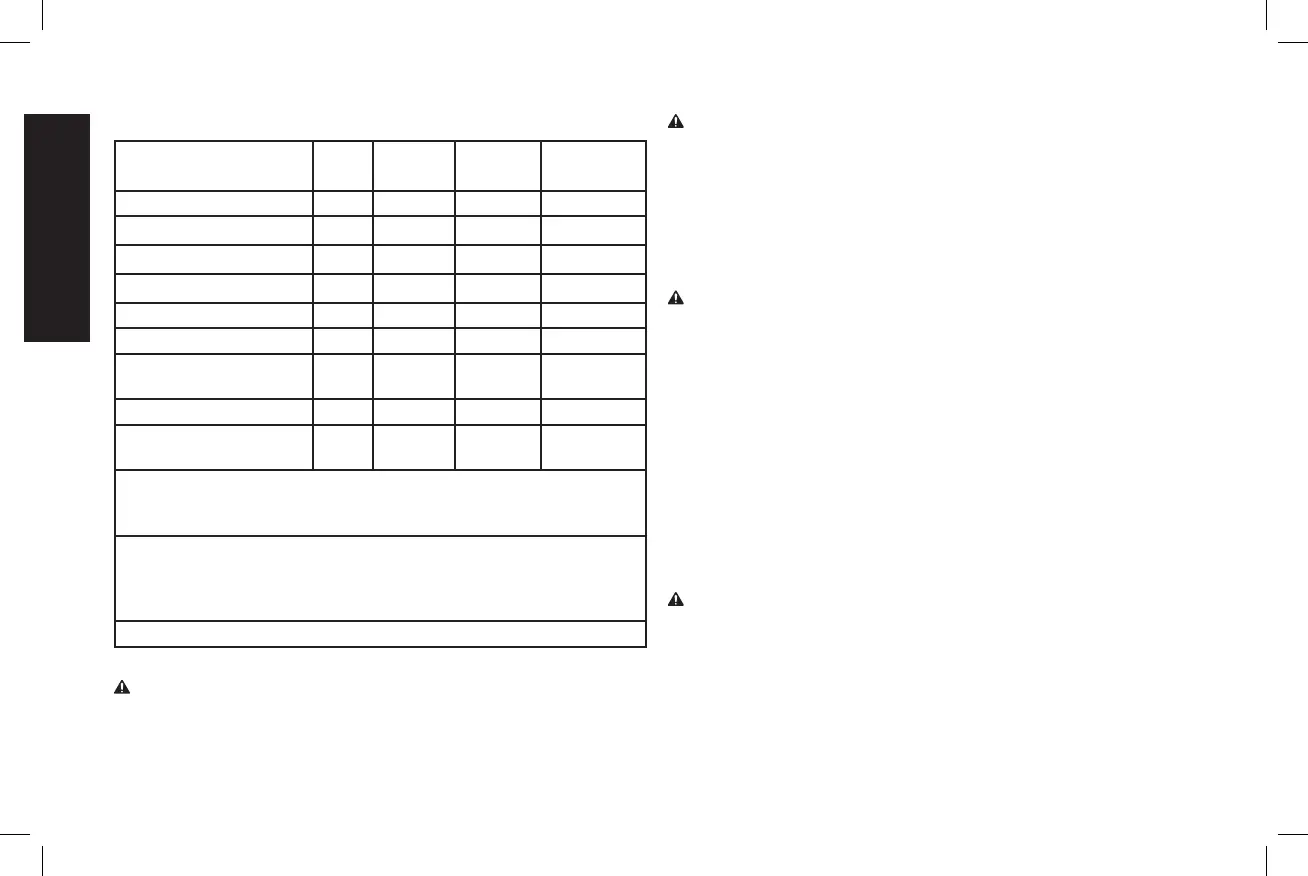

Maintenance Chart

Procedure

Daily Weekly Monthly 1 year or

200 Hours

Check safety valve

X

Inspect air filter +

X

Drain air tank

X

Check pump oil level

X

Change pump oil**+

X

Oil leak inspection

X

Check for unusual noise/

vibration

X

Check for air leaks*

X

Clean compressor

exterior

X

* To check for air leaks apply a solution of soapy water around

joints. While compressor is pumping to pressure and after pressure

cuts out, look for air bubbles to form.

** The pump oil must be changed after the first 20 hours of

operation. Thereafter, when using

SAe 5W-40 full synthetic

oil,

change oil every 200 hours of operation or once a year, whichever

comes first.

+ Perform more frequent in dusty or humid conditions

Checking Safety Valve (Fig. 1)

WARNING: Hot surfaces. Risk of burn. Aftercooler, pump head, and

surrounding parts are very hot, do not touch (see the Hot Surfaces

identied in Fig. 2). Allow compressor to cool prior to servicing.

WARNING: Risk of bursting. If the safety valve does not work

properly, over-pressurization may occur, causing air tank rupture or

anexplosion.

Before starting compressor, pull the ring on the safety valve to

make sure that the safety valve operates freely. If the valve is stuck

or does not operate smoothly, it must be replaced with the same

type of valve.

Checking Air Filter Element (Fig. 1)

WARNING: Hot surfaces. Risk of burn. Aftercooler, pump head, and

surrounding parts are very hot, do not touch (see the Hot Surfaces

identied in Fig. 2). Allow compressor to cool prior to servicing.

1. Ensure the On/Off switch (A) is in the OFFposition.

2. Allow unit tocool.

3. Remove air lter (N) fromunit.

4. Carefully pry lter top frombase.

5. Remove element from lterbase.

6. If element needs cleaning, blow out with air. Replace if needed.

Purchase replacement parts from your local dealer or authorized

service center. Always use identical replacementparts.

7. Place element back in lter base.

8. Snap lter top to lter base.

9. Reassemble air lter to unit. Ensure exhaust outlet pointsdown.

CAUTION: Risk of unsafe operation. Do not operate without air

inlet lter

Loading...

Loading...