ENGLISH

10

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn unit off and remove the battery pack

before making any adjustments or removing/

installing attachments or accessories. An

accidental start-up can causeinjury.

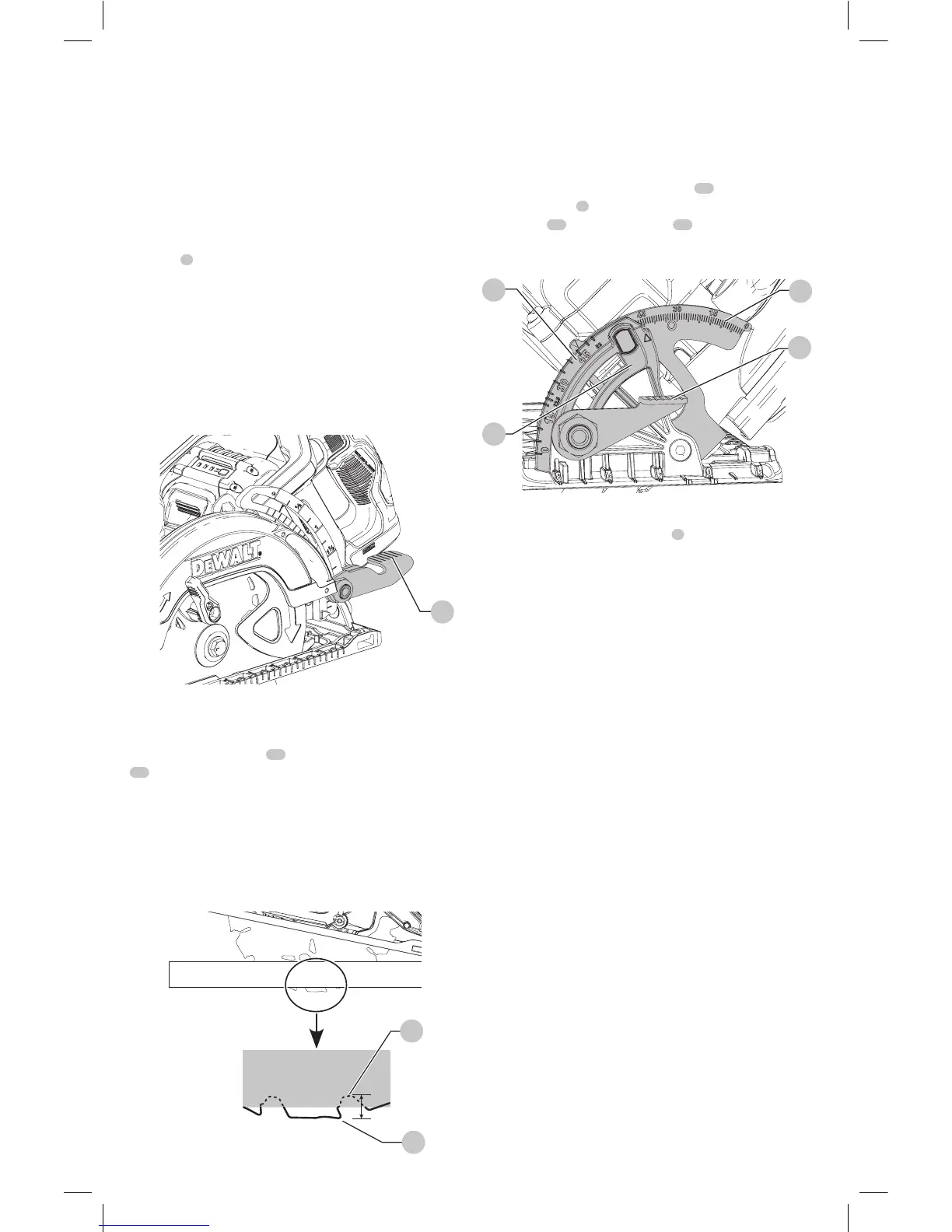

Cutting Depth Adjustment (Fig. A, E, F)

1. Hold the saw firmly. Lift the depth adjustment locking

lever

3

to move foot plate to obtain the desired depth

ofcut.

2. Lower the depth adjustment locking lever and tighten

securely to lock the depth of cut before operatingsaw.

The length of cut markings on the side of the foot plate are

accurate at full depth of cut only. Setting the saw at the

proper cutting depth keeps blade friction to a minimum,

removes sawdust from between the blade teeth, results in

cooler, faster sawing and reduces the chance ofkickback.

Fig. E

3

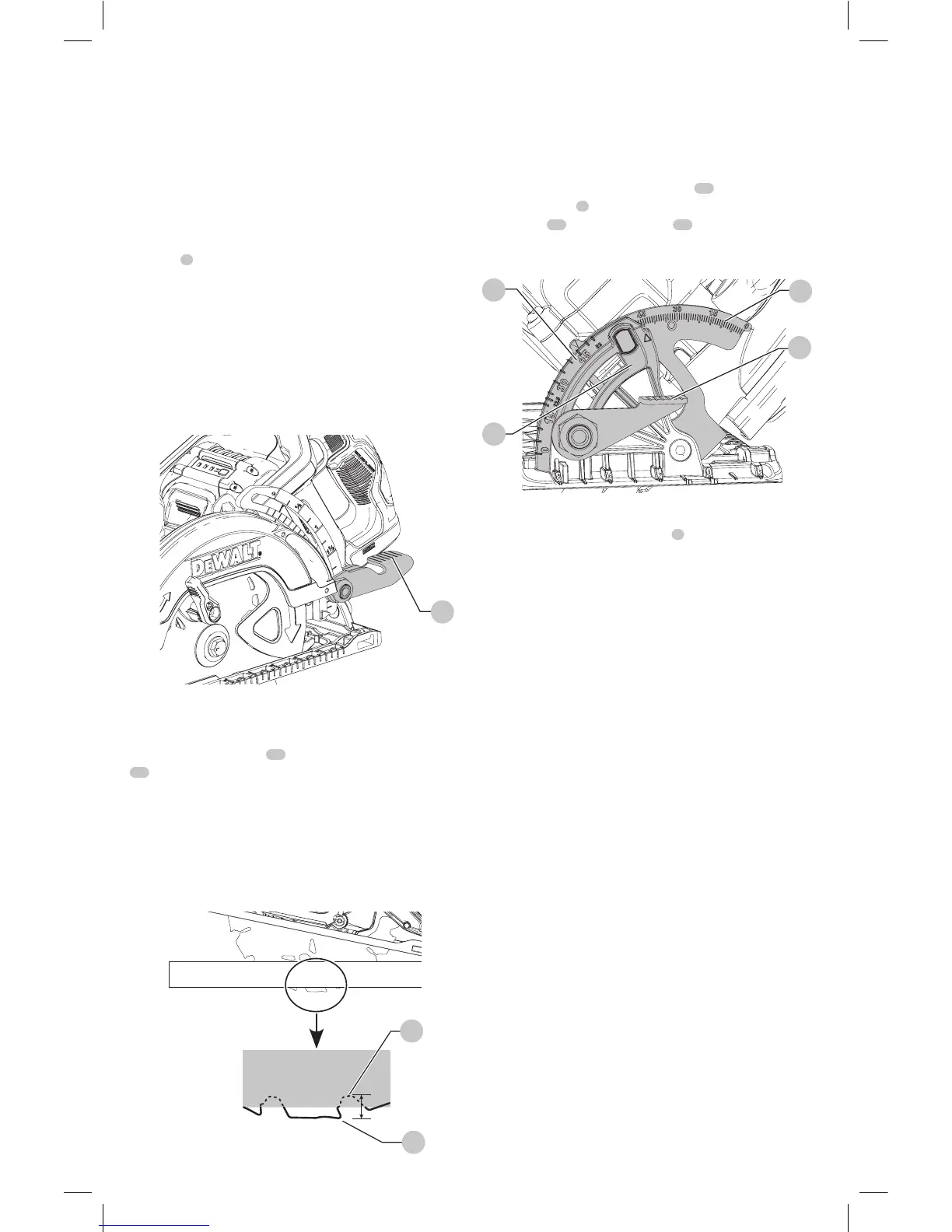

For the most efficient cutting action, set the depth

adjustment so that half of a blade tooth will project below

the material to be cut (refer to Figure F). This distance is

from the tip of the tooth

27

to the bottom of the gullet

28

(refer to inset of FigureF). This keeps blade friction at a

minimum, removes sawdust from the cut, results in cooler,

faster sawing and reduces the chance of kickback. A method

for checking for correct cutting depth is shown in FigureF.

Lay a piece of the material you plan to cut along the side of

the blade, as shown, and observe how much tooth projects

beyond thematerial.

Fig. F

28

27

Bevel Angle Adjustment (Fig. A, G)

The full range of the bevel adjustment is from 0˚ to

53˚. Detents are located at 22.5˚ and 45˚. The angle

quadrant is graduated in increments of 1˚. On the front

of the saw is a bevel angle adjustment mechanism which

consists of a calibrated angle quadrant

10

and a bevel

adjustment lever

9

. The angle quadrant allows for coarse

adjustment

16

or fine adjustment

17

to achieve better

accuracy incutting.

Fig. G

16

17

9

10

To set the saw for a bevel cut

1. Lift the bevel adjustment lever

9

and tilt foot plate

to the desired angle by aligning the pointer with the

desired anglemark.

2. Push the bevel adjustment lever down and tighten

securely to lock theangle.

Foot Plate Adjustment for 90˚ Cuts

(Fig. H)

If additional adjustment is needed

1. Adjust the saw to 0˚bevel.

2. Retract blade guard. Place the saw on bladeside.

3. Lift bevel adjustment lever. Place a square

against the blade and foot plate to adjust the

90˚setting.

4. Move the adjustment screw, located on the bottom of

the foot plate (Fig.H), so that the foot plate will stop at

the properangle.

5. Confirm the accuracy of the setting by checking the

squareness of an actual cut on a scrap piece ofmaterial.

Loading...

Loading...