3

Electrical Connection

The electric motor has been designed for one voltage only. Always check that the power supply corresponds to the

voltage on the rating plate. 230 V AC means your tool will operate on alternating current. As little as 10% lower voltage

can cause loss of power and can result in overheating. All DEWALT tools are factory tested; if this tool does not

operate, check the power supply. Your DEWALT tool is double insulated, therefore no earth wire is required.

• Young children and the infirm. This appliance is not intended for use by young children or infirm persons without

supervision. Young children should be supervised to ensure that they do not play with this appliance

– This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

– Children should be supervised to ensure that they do not play with the appliance.

• Replacement of the supply cord. If the supply cord is damaged, it must be replaced by the manufacturer or an

authorised D

EWALT Service Centre in order to avoid a hazard.

Accessories

WARNING: Since accessories, other than those offered by DEWALT, have not been tested with this product, use

of such accessories with this tool could be hazardous. To reduce the risk of injury, only DEWALT, recommended

accessories should be used with this product.

If you need any assistance in locating any accessory, please contact: Stanley Black & Decker, 82 Taryn Drive, Epping,

VIC 3076 Australia or call 1800 444 224 or (NZ). 0800 339 258.

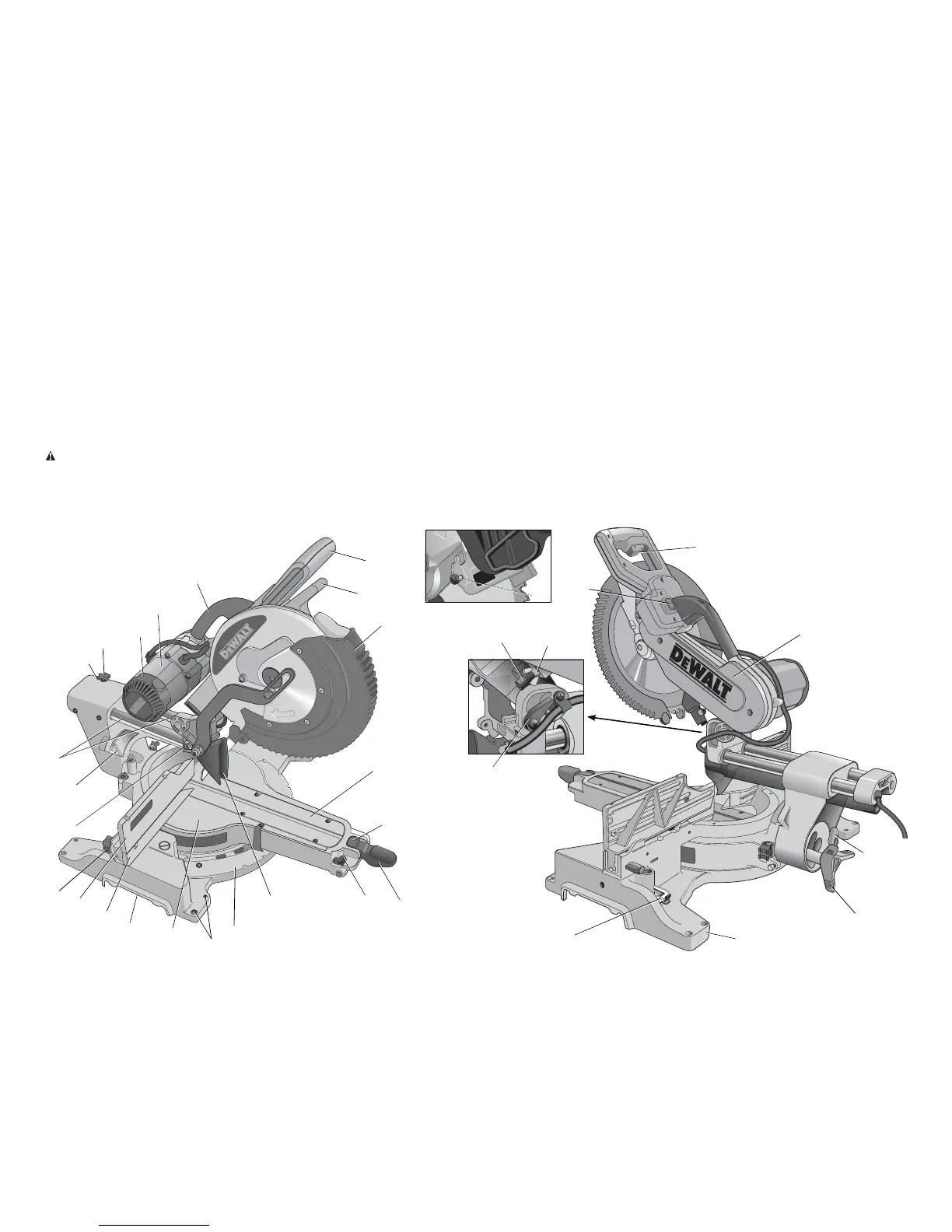

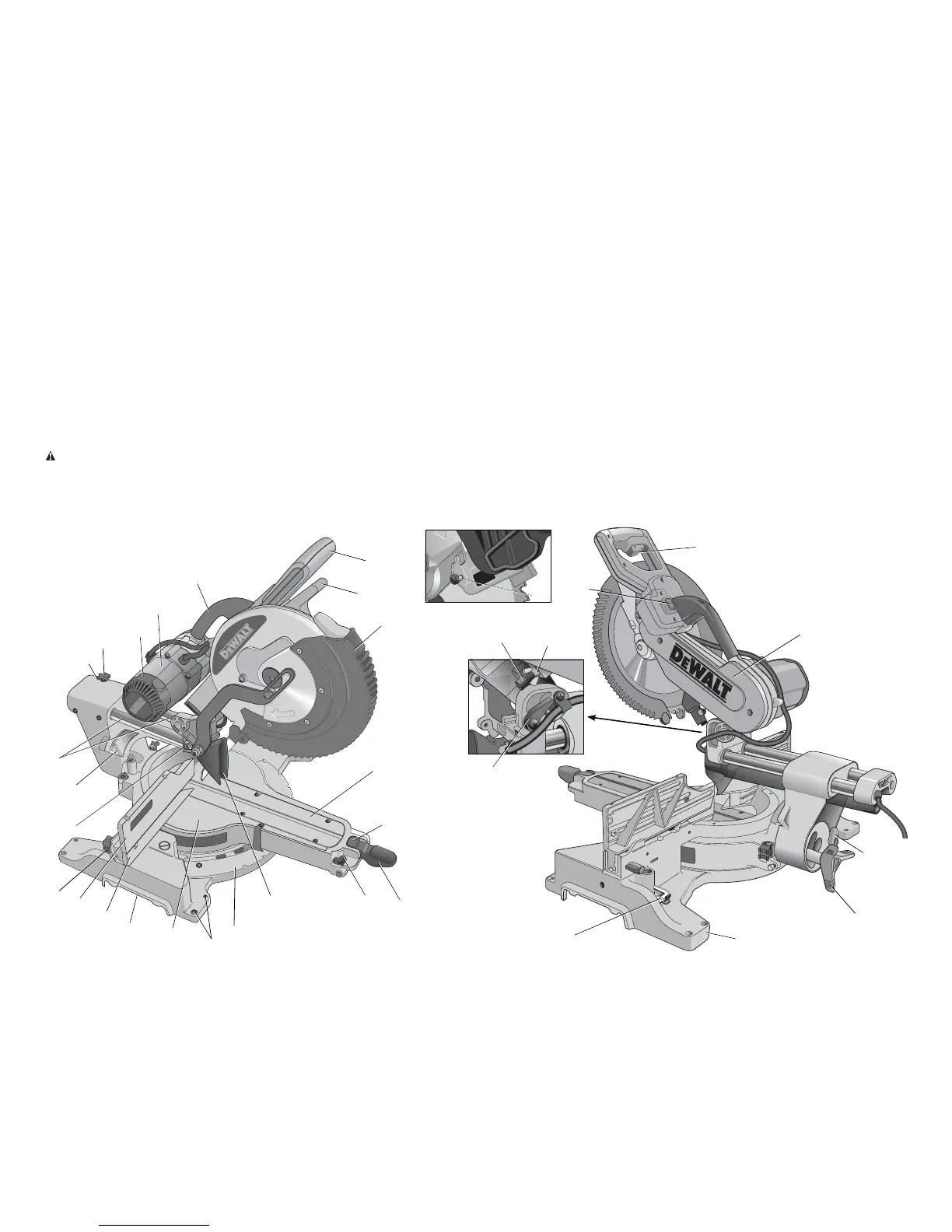

A. Lower guard

B.Guard bracket screw

C. Operating handle

D. Carrying handle

E. Motor housing

F. Motor endcap

G. Rail lock knob

H. Rail set screw adjustment

I. Head up lock lever release

J. Rails

K. Bevel scale

L. Lock down pin

M. Fence adjustment knob

N. Fence

O. Base fence

P. Hand indentation

Q. Table

R. Bench mounting holes

S. Mitre scale

T. Dust duct inlet

U. Mitre lock handle

V. Mitre latch button

W. Kerf plate

X. Trigger switch

Y. XPS

TM

on/off switch

Z. Wing nut

AA. Depth adjustment screw

BB. Depth stop

CC. Blade wrench

DD. Base

EE. Bevel lock knob

FF. 0° bevel stop

GG. Belt cover

HH. Miter latch override

AA

Z

BB

X

Y

CC

DD

EE

FF

GG

B

C

A

D

G

E

F

H

J

K

L

M

O

P

Q

R

S

T

U

V

W

N

FIG. 1

I

HH

Description (fig. 1)

Loading...

Loading...