66

NOTE: When using blades with a 5/8" (15.88 mm) diameter blade hole,

the blade adapter will not be used and should be stored in a safe place for

future use. The separate blade adapter is not available on all models.

5. Return the guard bracket to its original position and firmly tighten the

guard bracket screw to hold bracket in place.

WARNING:

• The guard bracket must be returned to its

original position and the guard bracket

screw tightened before activating the

saw.

• Failure to do so may allow the guard to

contact the spinning saw blade resulting

in damage to the saw and severe per-

sonal injury.

Transporting the Saw (fig. 1)

WARNING: To reduce the risk of serious personal injury, ALWAYS

lock the rail lock knob, mitre lock handle, bevel lock handle, lock down pin

and fence adjustment knobs before transporting saw.

In order to conveniently carry the mitre saw, a carrying handle (D) has

been included on the top of the saw arm.

• To transport the saw, lower the head and depress the lock down

pin (L).

• Lock the rail lock knob with the saw head in the front position,

lock the mitre arm in the full left mitre angle, slide the fence (N)

completely inward and lock the bevel lock knob (EE) with the saw

head in the vertical position to make the tool as compact as possible.

• Always use the carrying handle (D) or the hand indentations (P).

Features and Controls

WARNING: To reduce the risk of serious personal injury, turn off

the tool and disconnect it from the power source before attempting to

move it, change accessories or make any adjustments.

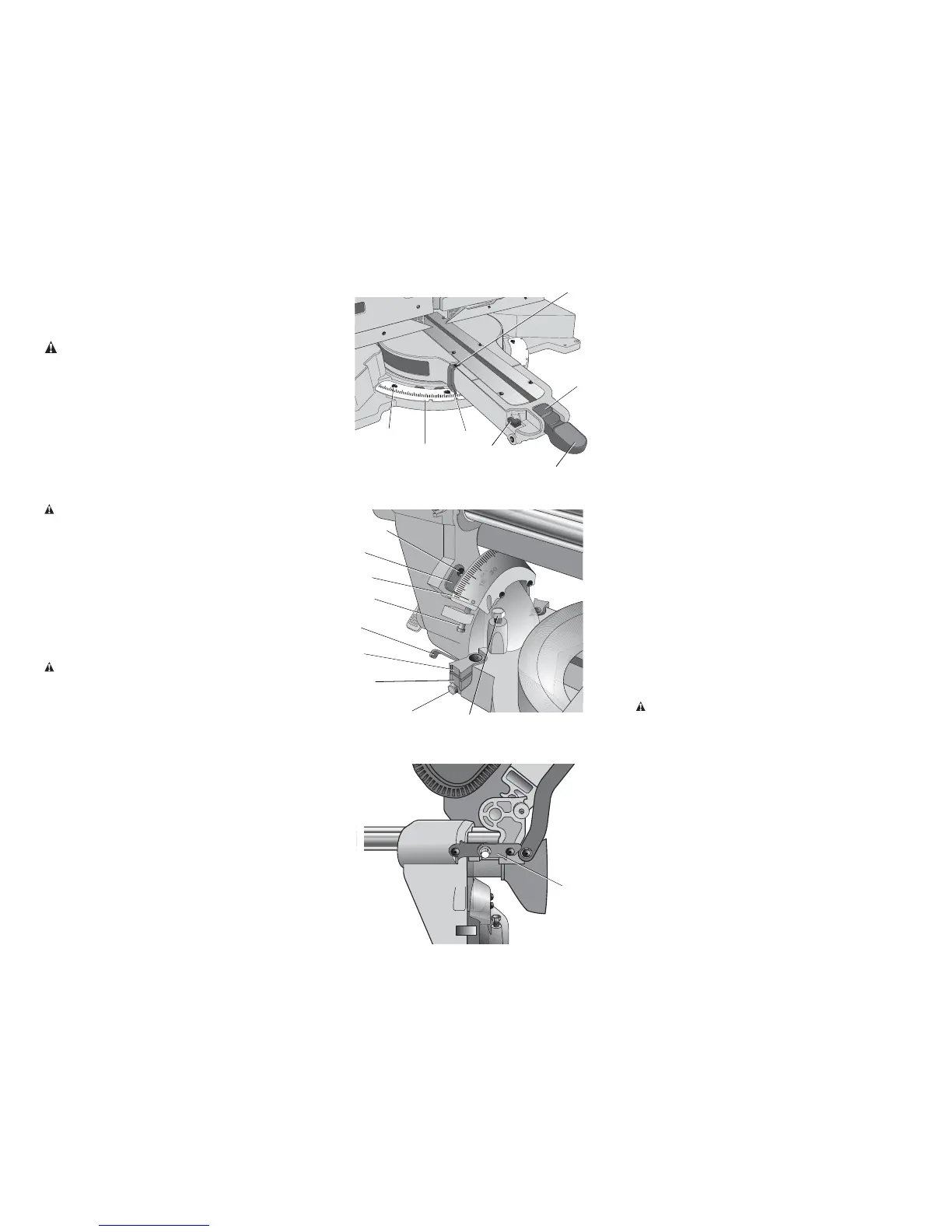

MITRE CONTROL (FIG. 11)

The mitre lock handle (U) and mitre latch button (V) allow you to mitre

your saw to 60° right and 50° left. To mitre the saw, lift the mitre lock

handle, push the mitre latch button and set the mitre angle desired on

the mitre scale (S). Push down on the mitre lock handle to lock the mitre

angle.

MITER LATCH OVERRIDE (FIG. 11)

The miter latch override (HH) allows your saw to override the common

stop angles. To override the common stop angles, push the miter latch

button and flip the miter latch override lever to the vertical position.

BEVEL LOCK KNOB (FIG. 1)

The bevel lock allows you to bevel the saw 49° left or right. To adjust the

bevel setting, turn the knob (EE) counterclockwise. The saw head bevels

easily to the left or to the right once the 0° bevel override knob is pulled.

To tighten, turn the bevel lock knob clockwise.

0° BEVEL OVERRIDE (FIG. 1)

The bevel stop override (FF) allows you to bevel the saw to the right past

the 0° mark.

When engaged, the saw will automatically stop at 0° when brought up

from the left. To temporarily move past 0° to the right, pull the bevel lock

knob (EE). Once the knob is released, the override will be reengaged. The

bevel lock knob can be locked out by twisting the knob 180°.

When at 0°, the override locks in place. To operate the override, bevel the

saw slightly to the left.

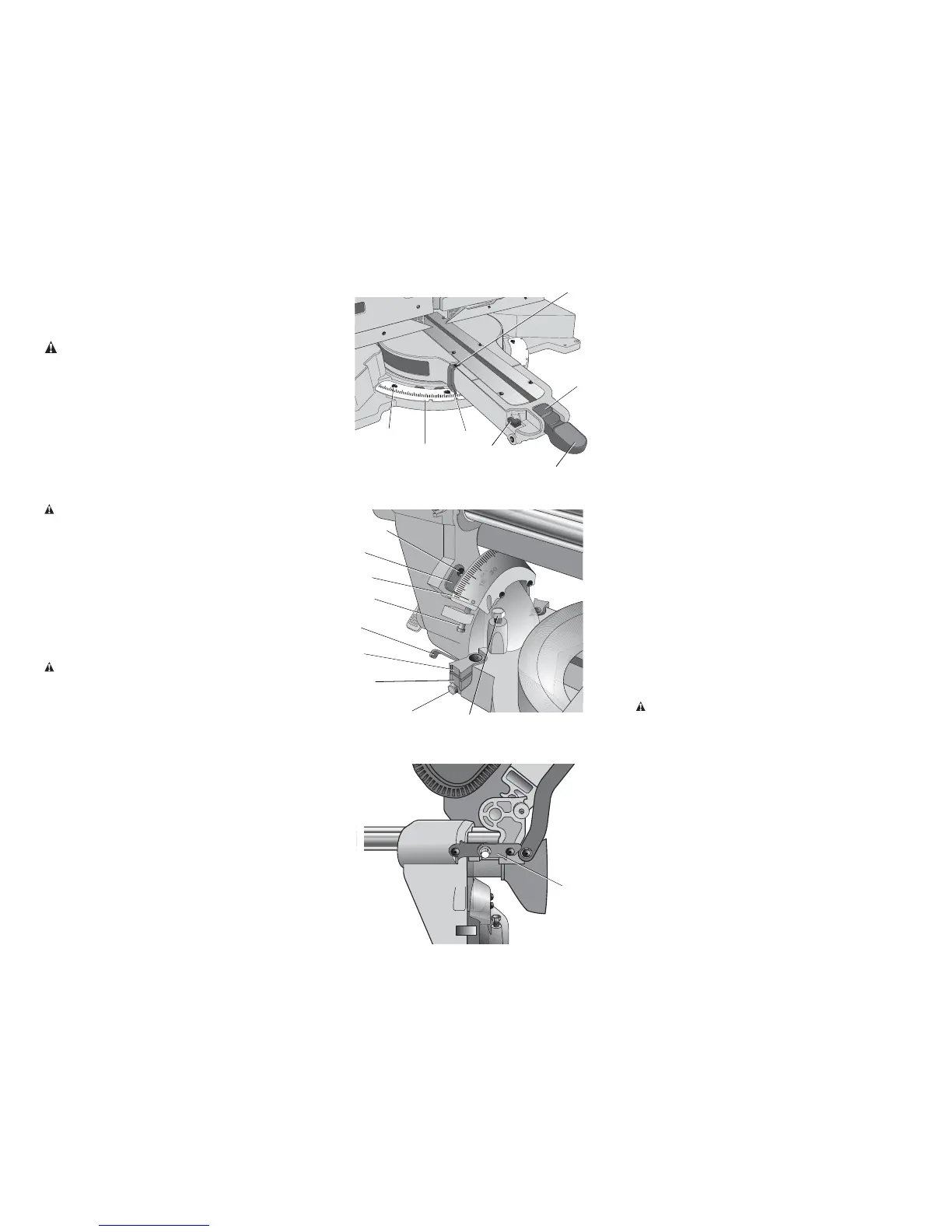

45° BEVEL STOP OVERRIDE (FIG. 12)

There are two bevel stop override levers, one on each side of the saw.

To bevel the saw, left or right, past 45°, push the 45° bevel override lever

(A1) rearward. When in the rearward position, the saw can bevel past

these stops. When the 45° stops are needed, pull the 45° bevel override

lever forward.

CROWN BEVEL PAWLS (FIG. 12)

When cutting crown molding laying flat, your saw is equipped to

accurately and rapidly set a crown stop, left or right (refer to Instructions

for Cutting Crown Molding Laying Flat and Using the Compound

Features). The crown bevel pawl (A3) can be rotated to contact the crown

adjustment screw.

To reverse the crown bevel pawl, remove the retaining screw, the 22.5°

bevel pawl (A2) and the 33.86° crown bevel pawl (A3). Flip the crown

bevel pawl (A3) so the 30° text is facing up. Reattach the screw to secure

the 22.5° bevel pawl and the crown bevel pawl. The accuracy setting will

not be affected.

22.5° BEVEL PAWLS (FIG. 12)

Your saw is equipped to rapidly and accurately set a 22.5° bevel, left

or right. The 22.5° bevel pawl (A2) can be rotated to contact the crown

adjustment screw (ZZ).

RAIL LOCK KNOB (FIG. 1)

The rail lock knob (G) allows you to lock the saw head firmly to keep it

from sliding on the rails (J). This is necessary when making certain cuts

or when transporting the saw.

DEPTH STOP (FIG. 1)

The depth stop (BB) allows the depth of cut of the blade to be limited.

The stop is useful for applications such as grooving and tall vertical cuts.

Rotate the depth stop forward and adjust the depth adjustment screw

(AA) to set the desired depth of cut. To secure the adjustment, tighten the

wing nut (Z). Rotating the depth stop to the rear of the saw will bypass the

depth stop feature. If the depth adjustment screw is too tight to loosen by

hand, the provided blade wrench (CC) can be used to loosen the screw.

LOCK DOWN PIN (FIG. 1)

WARNING: The lock down pin should be used ONLY when carrying or

storing the saw. NEVER use the lock down pin for any cutting operation.

To lock the saw head in the down position, push the saw head down,

push the lock down pin (L) in and release the saw head. This will hold the

saw head safely down for moving the saw from place to place. To release,

press the saw head down and pull the pin out.

SLIDE LOCK LEVER (FIG. 13, 23)

The slide lock lever (A6) places the saw in a position to maximize cutting

of base molding when cut vertically as shown in figure 23.

Adjustment

Your mitre saw is fully and accurately adjusted at the factory at the time

of manufacture. If readjustment due to shipping and handling or any other

reason is required, follow the instructions below to adjust your saw. Once

made, these adjustments should remain accurate.

MITRE SCALE ADJUSTMENT (FIG. 11, 14)

1. Unlock the mitre lock handle (U) and swing the mitre arm until the

mitre latch button (V) locks it at the 0° mitre position. Do not lock

the mitre lock handle.

FIG. 11

U

V

S

V V

WW

UU

FIG. 12

A1

A3

A2

ZZ

K

YY

XX

A4

A5

FIG. 13

A6

HH

Loading...

Loading...