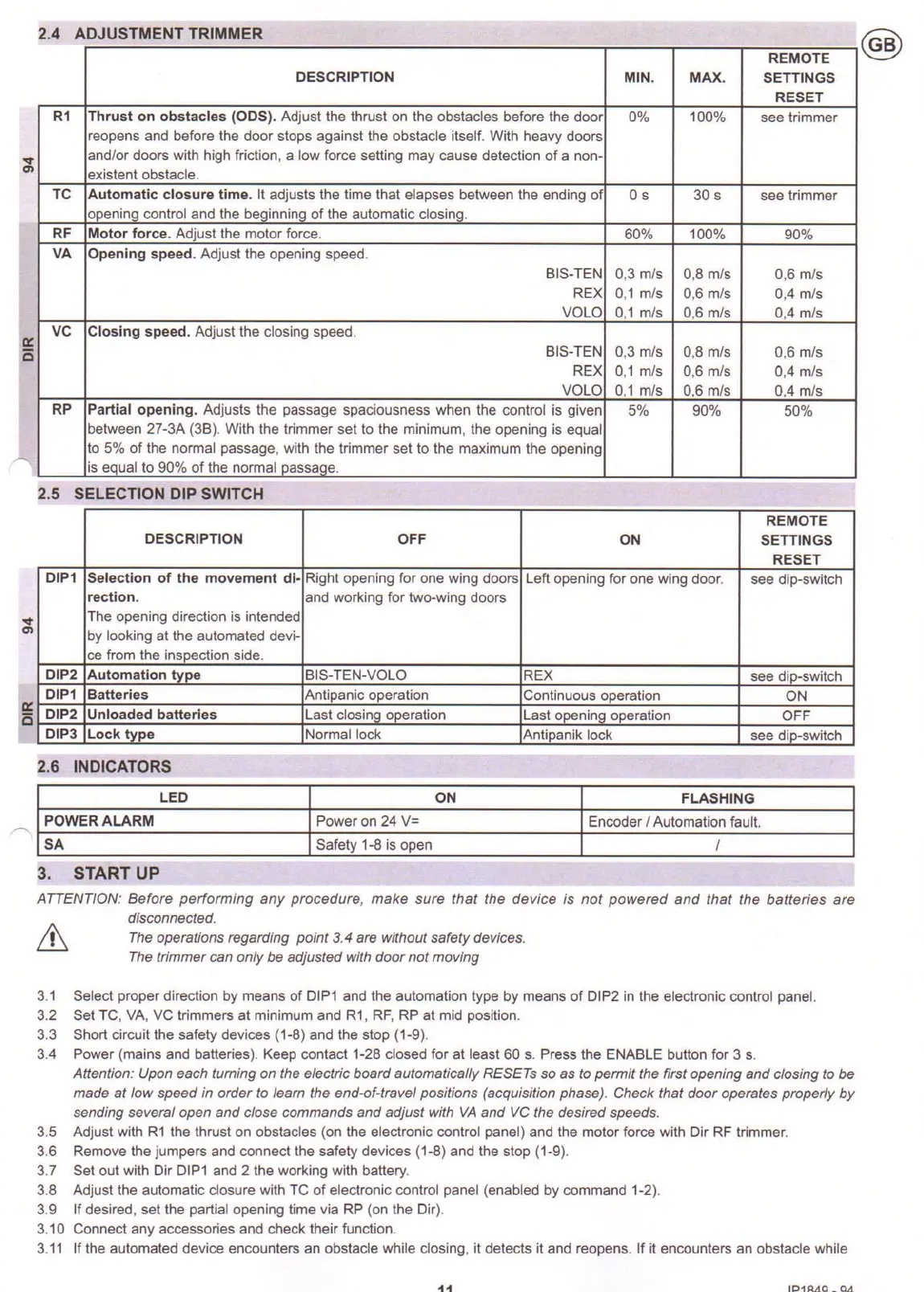

2.4 ADJUSTMENT TRIMMER

REMOTE

DESCRIPTION

MIN. MAX. SETTINGS

RESET

Rl Thrust on obstacles (ODS). Adjust the thrust on the obstacles before the door

0%

100%

see trimmer

reopens and before the door stops against the obstacle itself. With heavy doors

••

and lor doors with high friction. a low force setting may cause detection of a non-

en

existent obstacle.

TC Automatic ctosure time. It adjusts the time that elapses between the ending of

Os 30 s see trimmer

openinq control and the beqinninq of the automatic closinq.

RF Motor force. Adjust the motor force.

60% 100%

90%

VA Opening speed. Adjust the opening speed.

BIS-TEN

0,3 mls 0,8 mls 0,6 mls

REX 0,1 mls

0,6 mls 0,4 mls

VOLO 0,1 mls

0.6 mls

0,4 mls

VC Closing speed. Adjust the closing speed.

a::

BIS-TEN

0,3 mls 0,8 mls

0,6 mls

C

REX 0,1 mls 0,6 mls 0,4 mls

VOLO

0,1 mls 0,6 mls 0,4 mls

RP Partial opening. Adjusts the passage spaciousness when the control is given

5% 90% 50%

between 27-3A (3B). With the trimmer set to the minimum, the opening is equal

"

to 5% of the normal passage, with the trimmer set to the maximum the opening

is equal to 90% of the normal passage.

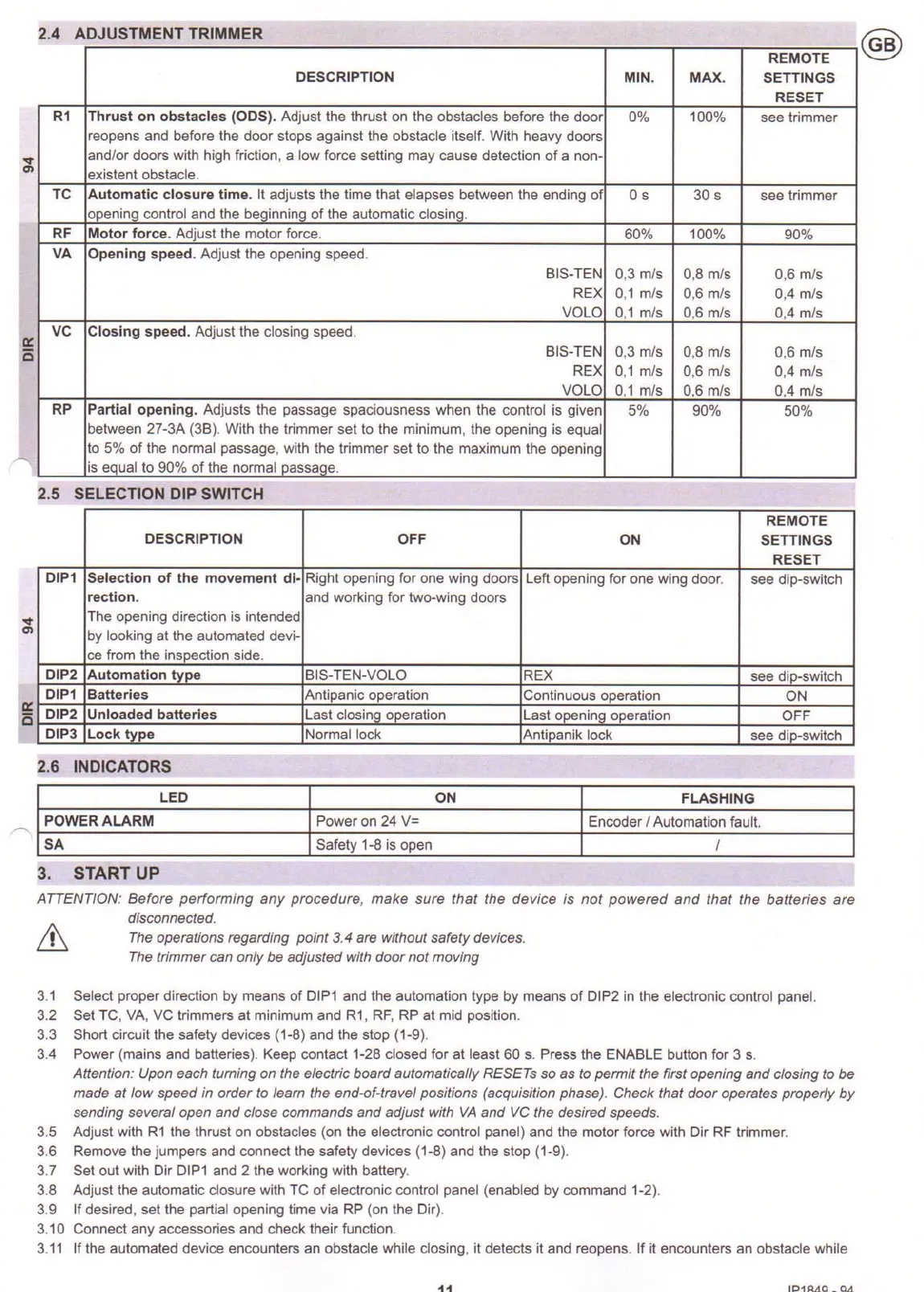

2.5 SELECTION DIP SWITCH

REMOTE

DESCRIPTION

OFF

ON SETTINGS

RESET

DIPl Selection of the movement di-

Right opening for one wing doors Left opening for one wing door.

see dip-switch

rection.

and working for two-wing doors

••

The opening direction is intended

en

by looking at the automated devi.

ce from the inspection side.

DIP2

Automation tvpe

BIS- TEN-VOLO

REX

see dip-switch

DIPl Batteries Antipanic operation

Continuous operation

ON

a::

DIP2 Unloaded batteries Last c10sinq operation

Last opening operation

OFF

0

DIP3 Lock type

Normal lock Antipanik lock

see dip-switch

2.6 INDICATORS

LED

ON

FLASHING

POWER ALARM

Power on 24 V-

Encoder

I

Automation faull.

SA Safety 1-8 is open

I

3. START UP

ATTENTION: Before performing any procedure, make sure that the device

is

not powered and that the batteries

are

disconnected.

ill

The operations regarding point 3.4 are without safety devices.

The trimmer can only be adjusted with door not moving

3.1 Select proper direction by means of DIPl and the automation type by means of DIP2 in the electronic control panel.

3.2 Set TC, VA, VC trimmers at minimum and Rl, RF, RP at mid position.

3.3 Short circuit the safety devices (1-8) and the stop (1-9).

3.4 Power (mains and batteries). Keep contact 1-28 closed for at least 60 s. Press the ENABLE button for 3 s.

Attention: Upon each turning on the electric board automatically RESETs so as to permit the first opening and closing to be

made at low speed in order to learn the end-of.travel positions (acquisition phase). Check that door operates properly by

sending several open and close commands and adjust with

VA

and

VC

the desired speeds.

3.5 Adjust with Rl the thrust on obstacles (on the electronic control panel) and the motor force with Dir RF trimmer.

3.6 Remove the jumpers and connect the safety devices (1-8) and the stop (1-9).

3.7 Set out with Dir DIPl and 2 the working with battery.

3.8 Adjust the automatic closure with TC of electronic control panei (enabled by command 1-2).

3.9 If desired, set the partial opening time via RP (on the Dir).

3.10 Connect any accessories and check their function.

3.11 tf the automated device encounters an obstacle while closing, it detects it and reopens. If it encounters an obstacle while

11

IP1A4Q _ CIA.

Loading...

Loading...