26

Dixie Chopper • 6302 E. County Road 100 N. • Coatesville, IN • 46121 • www.dixiechopper.com

Routine Maintenance (Continued)

Verify Safety Interlock System

With parking brake on, steering levers in the neutral lock position, and deck blades disengaged,

start mower while sitting in the seat. When engine starts, lift up off the seat. The engine should shut

down. If engine continues to run, see an authorized Dixie Chopper dealer to service the safety inter-

lock system.

Visually Inspect Unit for Loose Hardware and/or Damaged Parts

Walk around mower to visually inspect and tighten, if necessary, all hardware. Refer to Parts Manual

for proper torque specications. Pay particular attention to wheel axle nuts, lug nuts, and blade bolts.

Visually inspect tires

Front tire pressure is 12-18 psi. Rear tire pressure is 5-7psi.

Check Fuel Lines and Fittings

All fuel lines and ttings should be checked for compromised integrity with the use of a soapy water

solution in a spray bottle. Simply spray all fuel lines and ttings with the solution and look for bubbles,

which indicate CNG escaping to atmosphere, caused by a compromise in the line, tting, or seal

integrity. If bubbles are seen, see an authorized Dixie Chopper Dealer for service, before starting

mower.

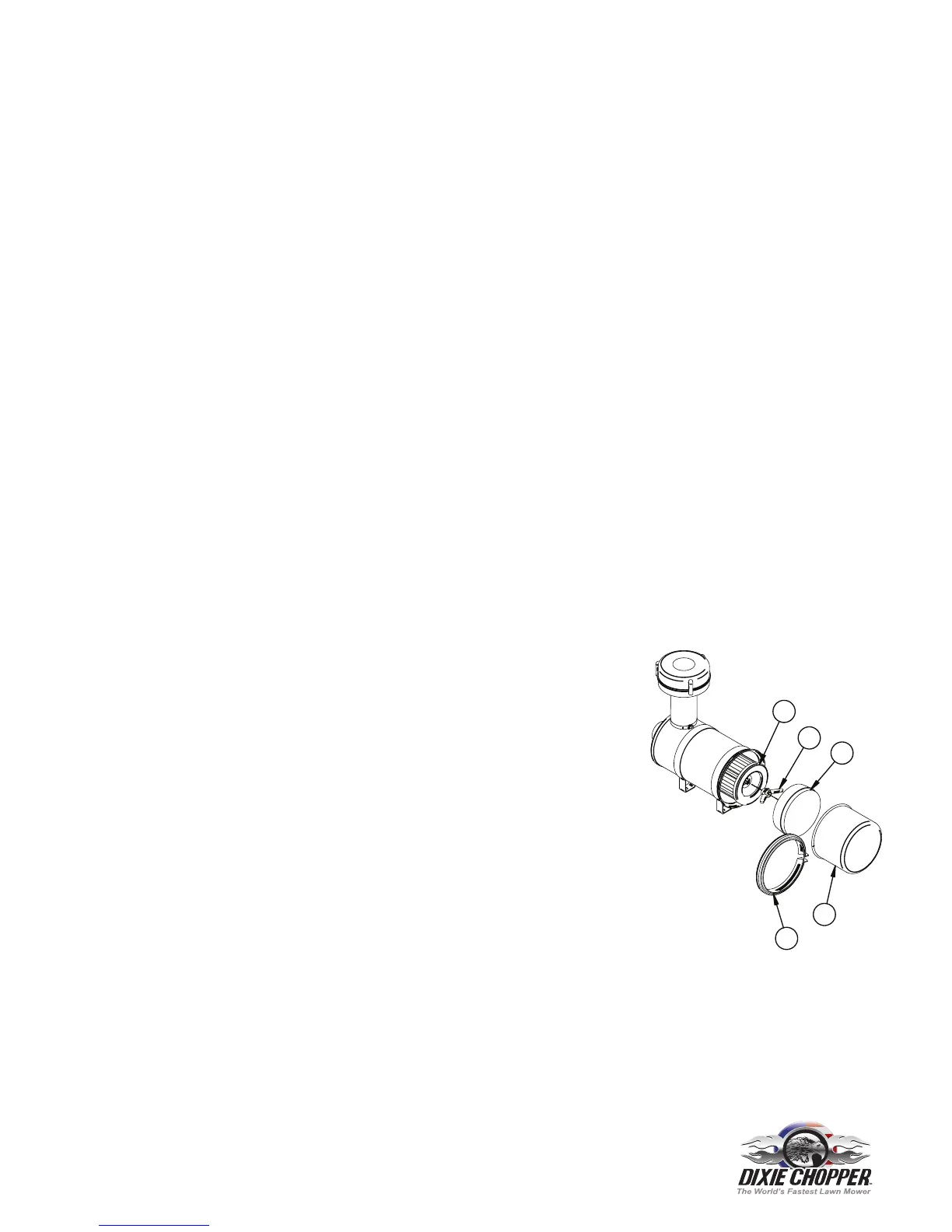

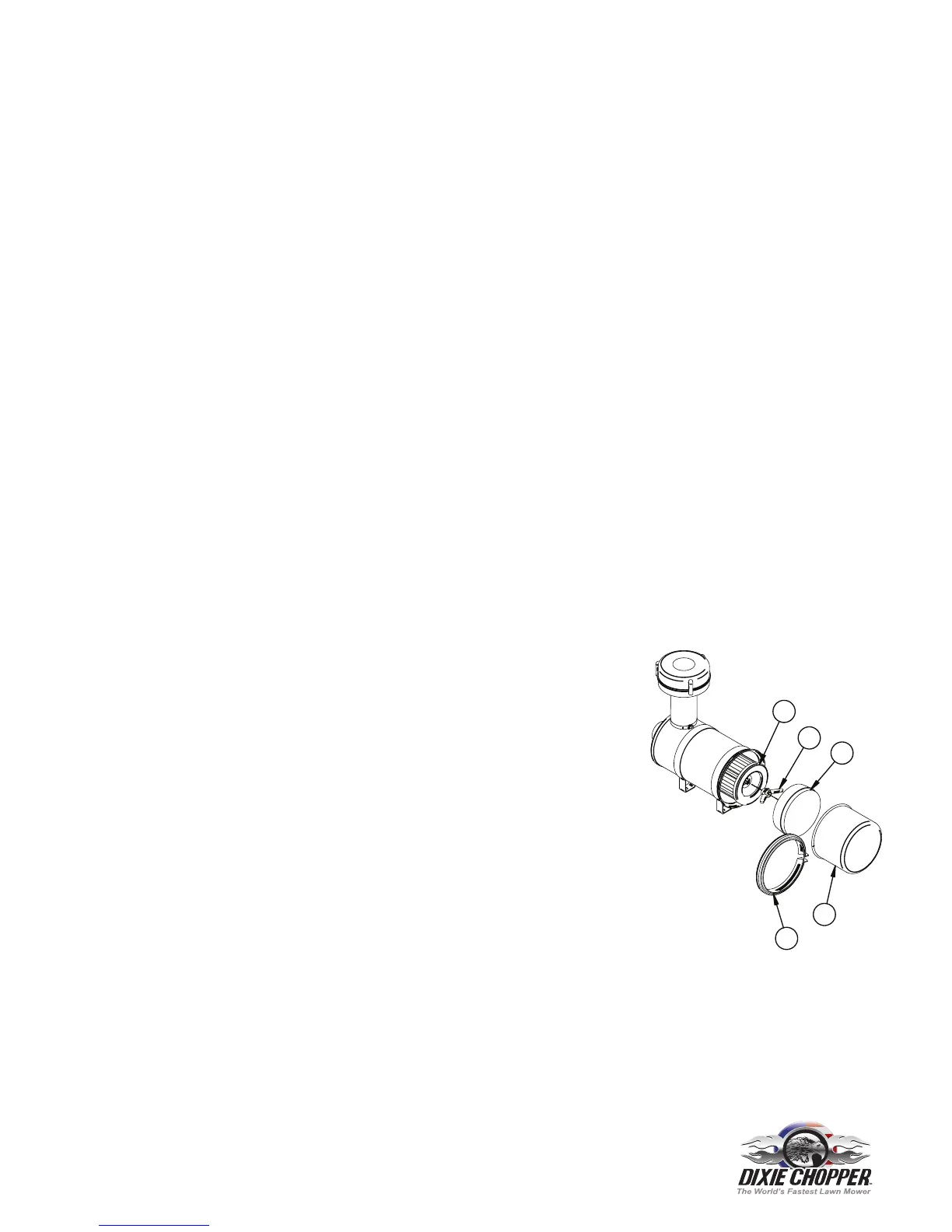

Clean Donaldson Air Filter End Cap & Engine Air Filter

In order to clean the Donaldson air lter end cap and engine

air lter you must rst Remove the (2) air cleaner cannister clamp.

Next, remove the (1) air lter cup housing. The next step is to

remove the (3) Donaldson air lter end cap, and using a shop vac

or a household vaccuum, vaccuum clean the end cap. Lastly,

remove the (4) air lter wing nut and take the (5) air lter out and

clean it, also using a shop vac or household vaccuum. All that’s

left is reassembly. See image at the right for reference.

Loading...

Loading...