32

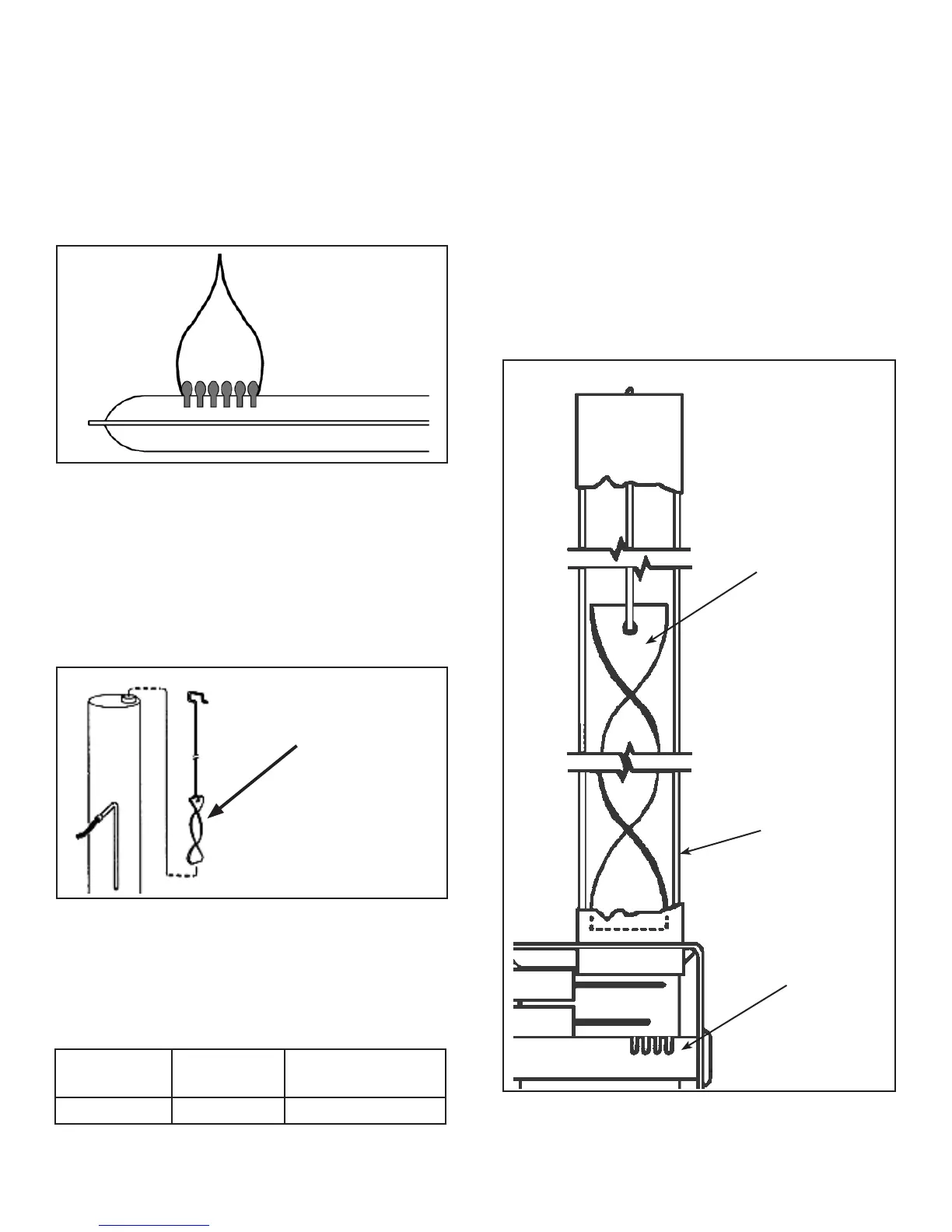

8.4 Burner

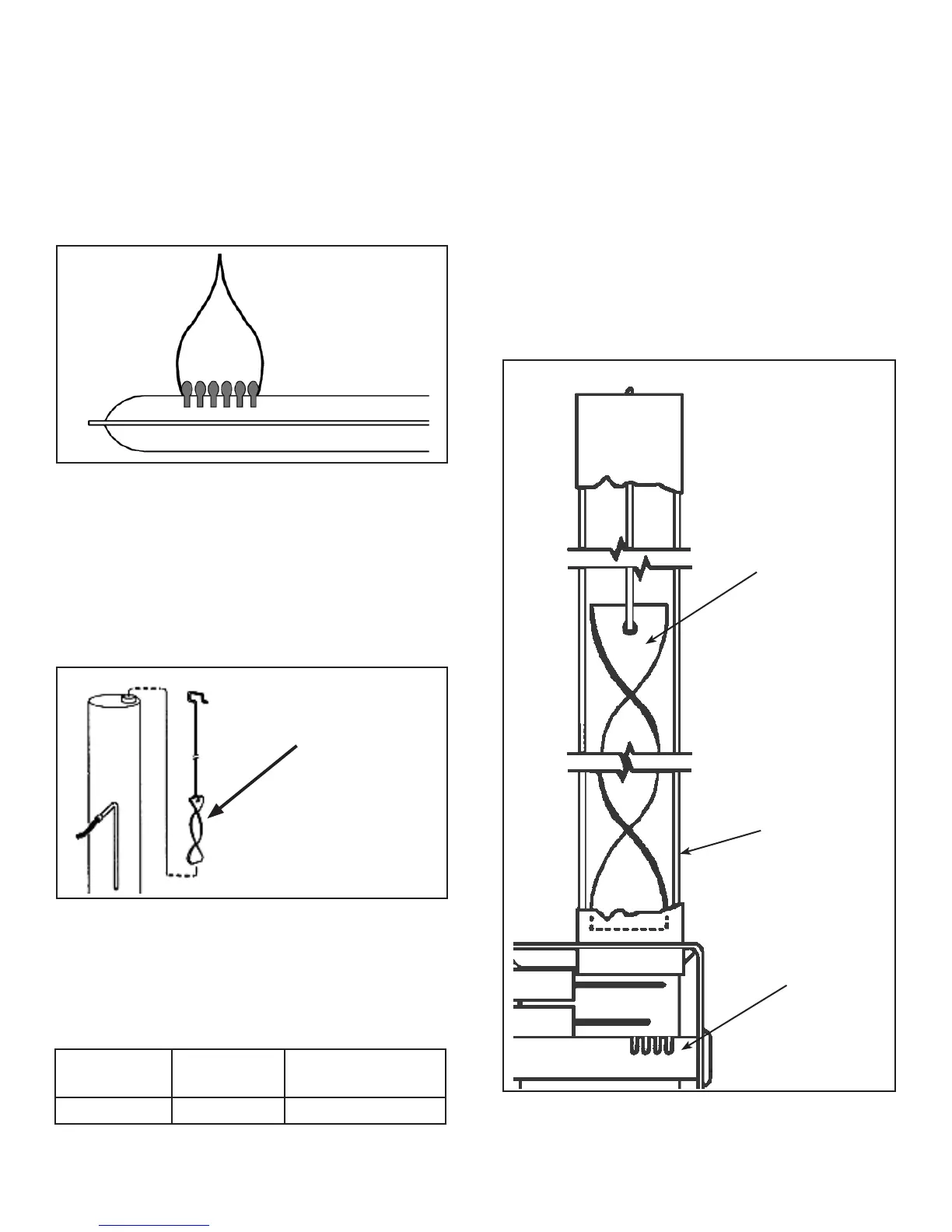

8.5 Flue Bafe

The slots in the burner should be directly below the ue

tube. The burner should be cleaned periodically, at least

once a year. Soak the burner in an alcohol based sol-

vent and allow to air dry. If the burner does not have a

good ground it can/will cause erratic gas operation. The

electrode should spark to the burner not the ue tube or

thermocouple.

The ue bafe (spiral bafe) is a twisted piece of metal

that hangs in the ue tube to slow the heat from the ame

to the proper location on the cooling unit. If the ue bafe

is too high or low the heat will not be transferred to the

cooling unit properly. Low cooling on gas operation.

MODEL ABOVE

BURNER

SIZE

RM1350 1-1/4” 6˝ X 15/16”

Lack of heat transfer to the cooling unit will cause low cool-

ing performance in the gas mode. It should be cleaned

periodically, at least once a year. The proper length and

position of the bafe above the burner should be as shown

in the chart : Always Refer to parts list on the model/

product number unit you are currently working on.

8.6 Flue Tube

The ue tube is welded to the boiler of the cooling unit. As

heat travels up the ue tube and slows at the ue bafe it

transfers heat to the cooling unit. Carbon build up will not

allow the heat transfer to the cooling unit and cause lack

of cooling on gas. In a rough riding coach there have been

rare cases where the ue will separate and create lack of

heat transfer to the cooling unit. The ue tube must be

cleaned periodically, at least once a year. Clean by using

ue brush, Dometic Part no. 0151404001.

Flue Tube

Flue Bafe

Burner

Bafe

Loading...

Loading...