DL06K Interim Tire-4 Diesel Engine Technical Information

28

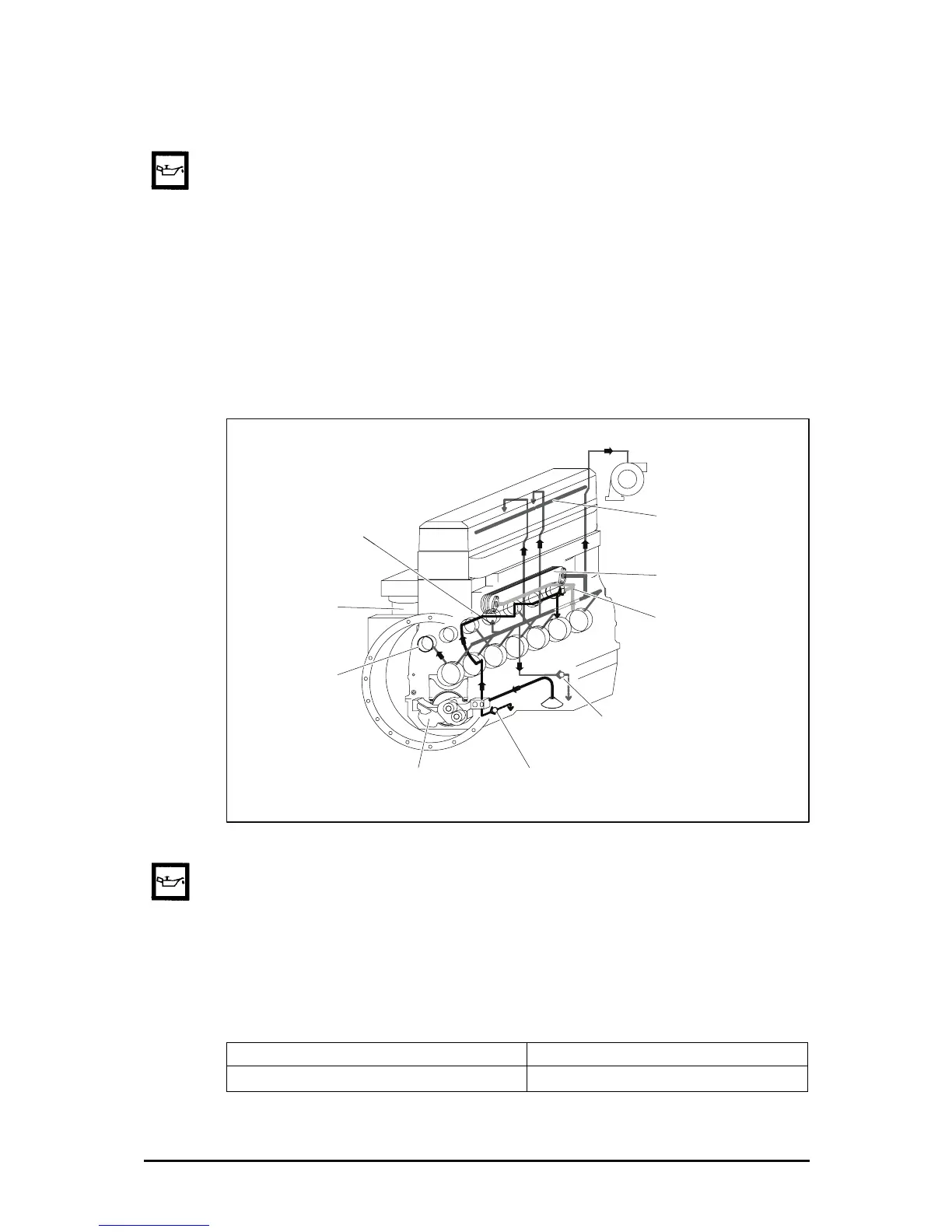

2.3.12. Lubrication system

z The engine runs with the forced lubrication system. Oil pressure is generated and

supplied by gear revolution of the oil pump, which is meshed directly with the

crankshaft located at the rear side of the cylinder block.

z The oil pump sends oil sucked by the oil pan with the intake pipe via the oil filter

and oil cooler. Then, oil is supplied to the crankshaft bearing, camshaft bearing,

and rocker arm for lubrication. In addition, the turbo charger is also connected to

the engine lubricant circuit, and supplies oil for engine break operation.

z Lubricant is sprayed around cylinder blocks and timing gears. Each cylinder has

the oil injection nozzle to cool down the inside of the piston. Engine oil is cleaned

by passing through the oil filter.

2.3.13. Engine oil

z Check the oil amount with an oil level gauge, and refill oil, if necessary. Check the

oil level after stopping the engine. If the engine was running, measure the oil level

after 5 ~ 10 minutes, so that oil is returned to the crank case. The oil level should

be between upper and lower limit of the gauge.

z Engine oil should be replaced regularly, and the oil filter cartridge should be

replaced at the same time.

- First oil change

First oil change After 50 Hr operating

Excavator, fork lift Every 500Hours

Oil pump relief valve

(10bar)

Oil spray nozzle

(for piston cooling)

Air compressor

Camshaft bush

Oil pump

Oil pressure adjustment valve

(5bar)

Oil filter

(bypass valve 2.1 bar)

Oil cooler

Rocker arm shaft

Turbo charger

EK1OM015

Loading...

Loading...