DL06K Interim Tire-4 Diesel Engine Disassembly and Reassembly of Major Components

87

2) Piston rings

a) Visual check

z Replace the piston rings with new ones if detected worn or broken when the

engine is overhauled.

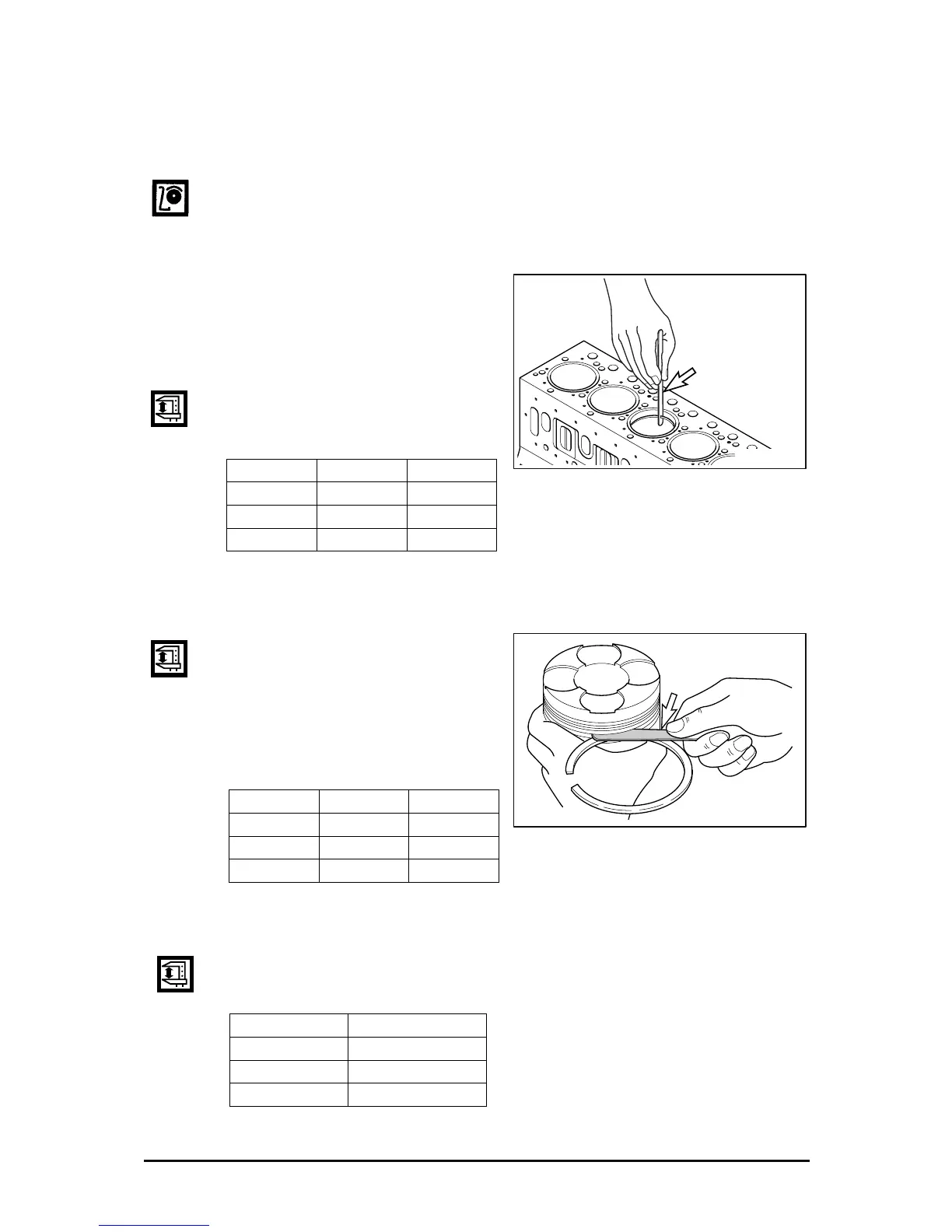

b) Piston ring gap

z Insert the piston ring into the upper

portion of the cylinder liner bore so

that it is held at a right angle to the

cylinder liner wall.

z Measure the piston ring gap with a

feeler gauge.

(mm)

Standard Limit

1st ring 0.30 ~ 0.45 1.5

2nd ring 0.60 ~ 1.80 1.5

Oil ring 0.25 ~ 0.45 1.5

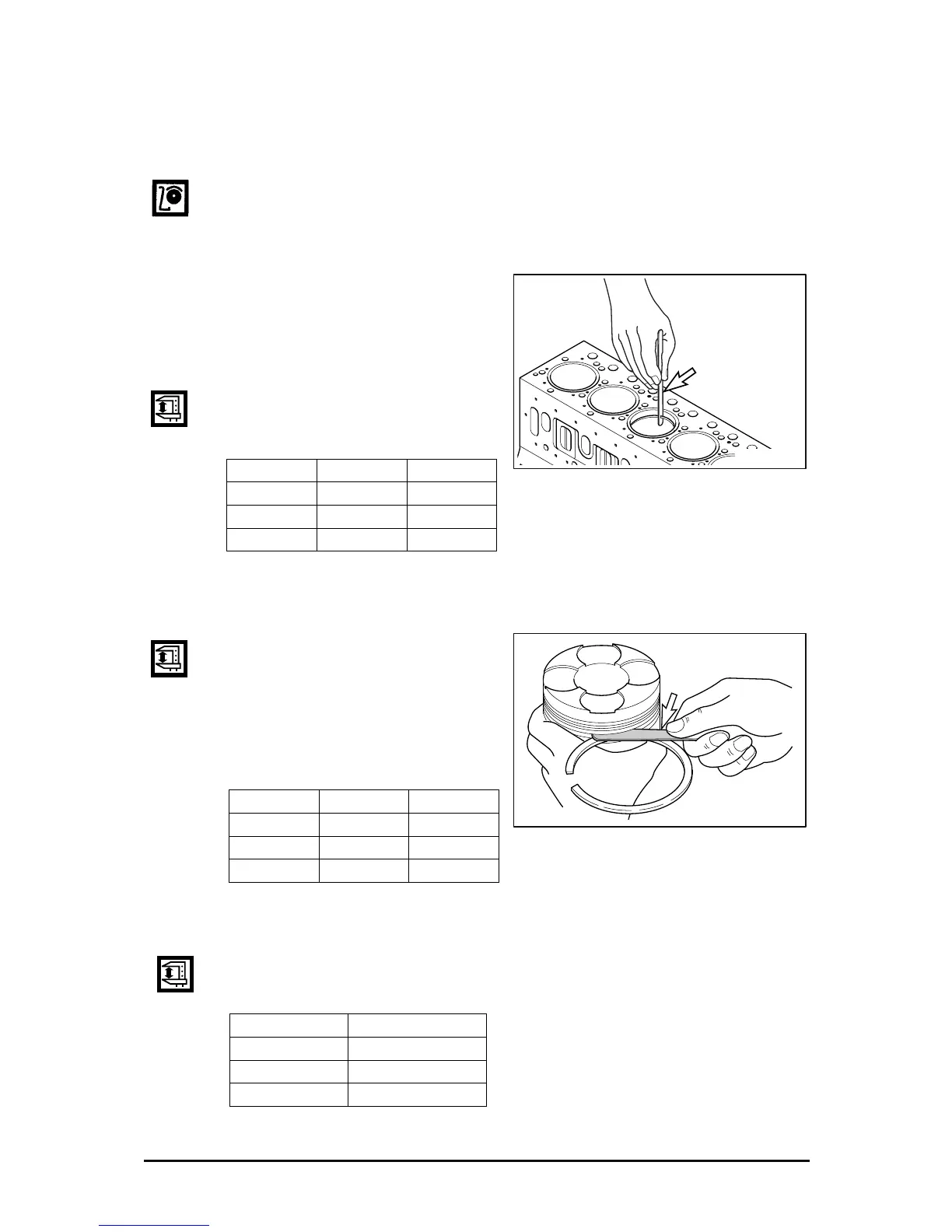

c) Piston ring side clearance

z Fit the compression ring and oil ring in the piston ring groove.

z With a feeler gauge, measure side

clearance of each ring, and replace

either the ring or piston if the

measured value is beyond the

specified limit.

(mm)

d) Piston ring tension

z With a tension tester, measure piston ring tension. Replace the piston ring if the

measured value is beyond the limit.

Standard Limit

1st ring - -

2nd ring 0.05 ~ 0.09 0.15

Oil ring 0.03 ~ 0.07 0.15

Standard

1st ring 1.47 ~ 2.21 kg

2nd ring 1.49 ~ 2.23 kg

Oil ring 4.08 ~ 5.52 kg

EH6OM044

Feeler gauge

EE2OM118

Feeler

gauge

Loading...

Loading...