DL06K Interim Tire-4 Diesel Engine Disassembly and Reassembly of Major Components

89

4) Connecting rod inspection

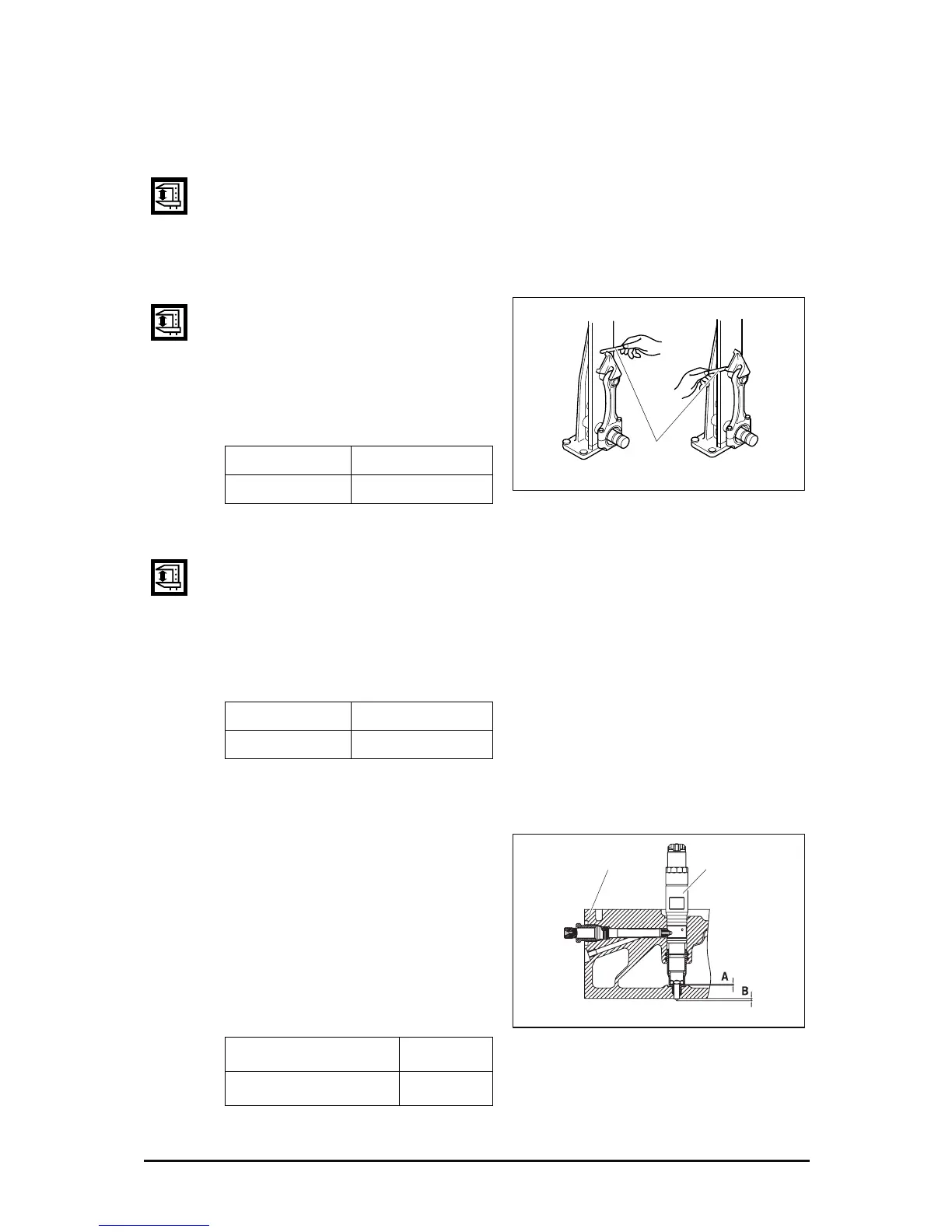

a) Distortion

z Check the connecting rod for distortion. As shown in the figure below, install the

connecting rod to the connecting rod tester, and check for distortion using a

feeler gauge.

z If the connecting rod is found distorted, never re-use it but replace with a new one.

b) Holes alignment (parallelism)

z Measure the alignment of the

connecting rod piston pin bushing holes

with connecting rod big end holes.

z At this time also, use both connecting

rod tester and feeler gauge.

(mm)

c) Wear

z Assemble the connecting rod to the crankshaft and measure connecting rod big

end side clearance using a feeler gauge.

z Assemble the connecting rod to the piston and measure connecting rod small

end side clearance.

z If the measured values are beyond the limit, replace the connecting rod.

(mm)

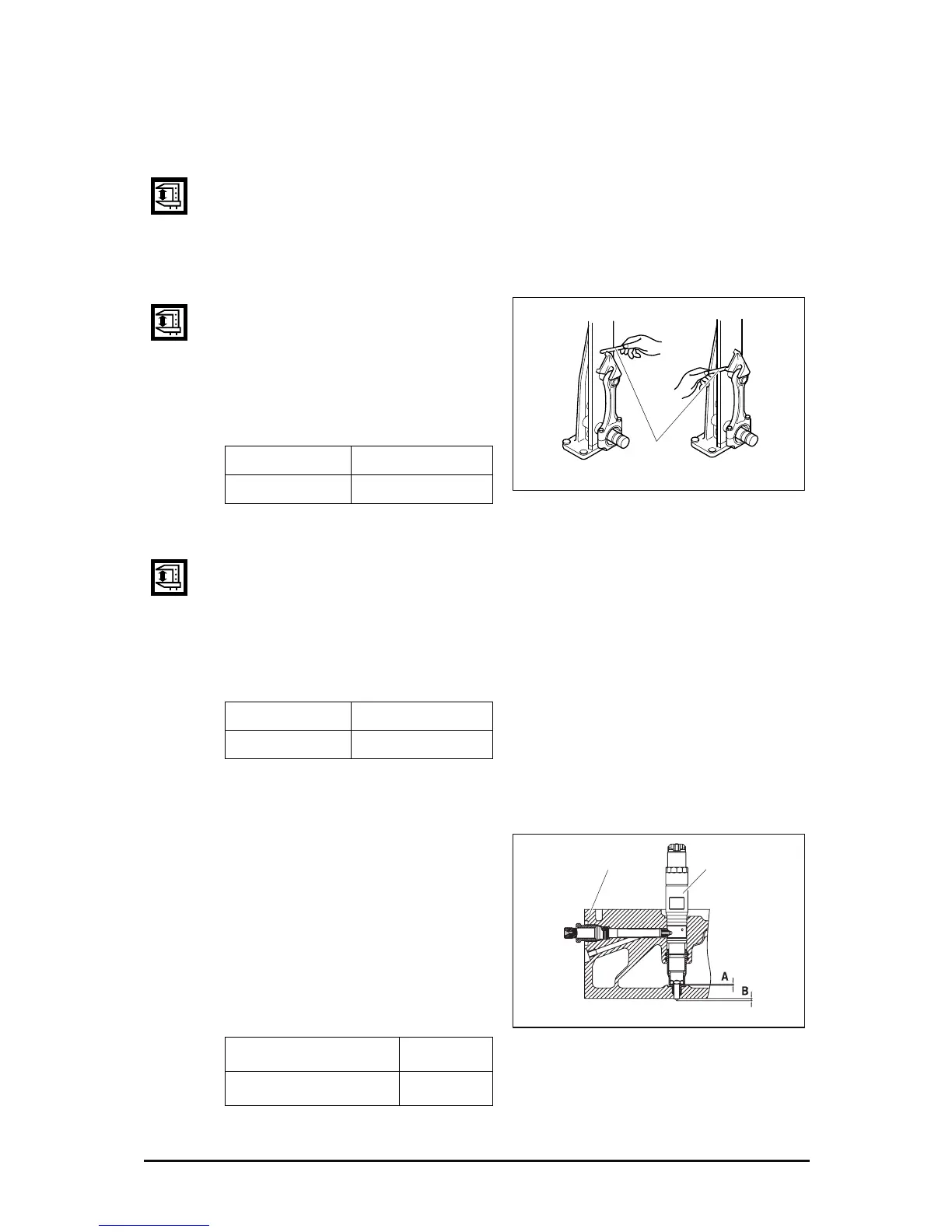

3.2.8. Injector projection

z Insert a seal ring on the cylinder head

and assemble the injector. (Refer to

3.3 chapter for assembly order)

z Measure the clearance between the

cylinder head bottom and injector tip.

If the measured valves are beyond

the limit, replace the seal ring.

(mm)

Standard Limit

0.02 Under 0.1

Standard Limit

0.17 ~ 0.30 0.50

A

(Thickness of seal ring)

2.0

B

(Projection of nozzle)

3.0

EA0M4034

Feeler

gauge

EE1OM075

Cylinder head

Injector

Loading...

Loading...