Commissioning and Operation

- 155 -

4.8. Adjustment of Valve Clearance

4.8.1. General information

The valve clearances are to be adjusted at the times of the following situations.

After initial 1,000km (50hours) operation.

When the engine is overhauled and the cylinder heads are disassembled.

When severe noise comes from valve train.

When the engine is not normally operated, even though there is no trouble in the fuel system.

The valve clearance of the cold engine are as follows.

4.8.2. Adjusting order of the valve clearance

1) After letting the #1 cylinder's piston come at the compression top dead center by turning the

crankshaft, adjust the valve clearances.

2) Loosen the lock nuts of rocker arm adjusting screws and push the feeler gauge of specified value

between a rocker arm and a valve stem and adjust the clearance with adjusting screw respectively

and then tighten with the lock nut.

3) As for the valve clearance, adjust it when in cold, as follow.

-

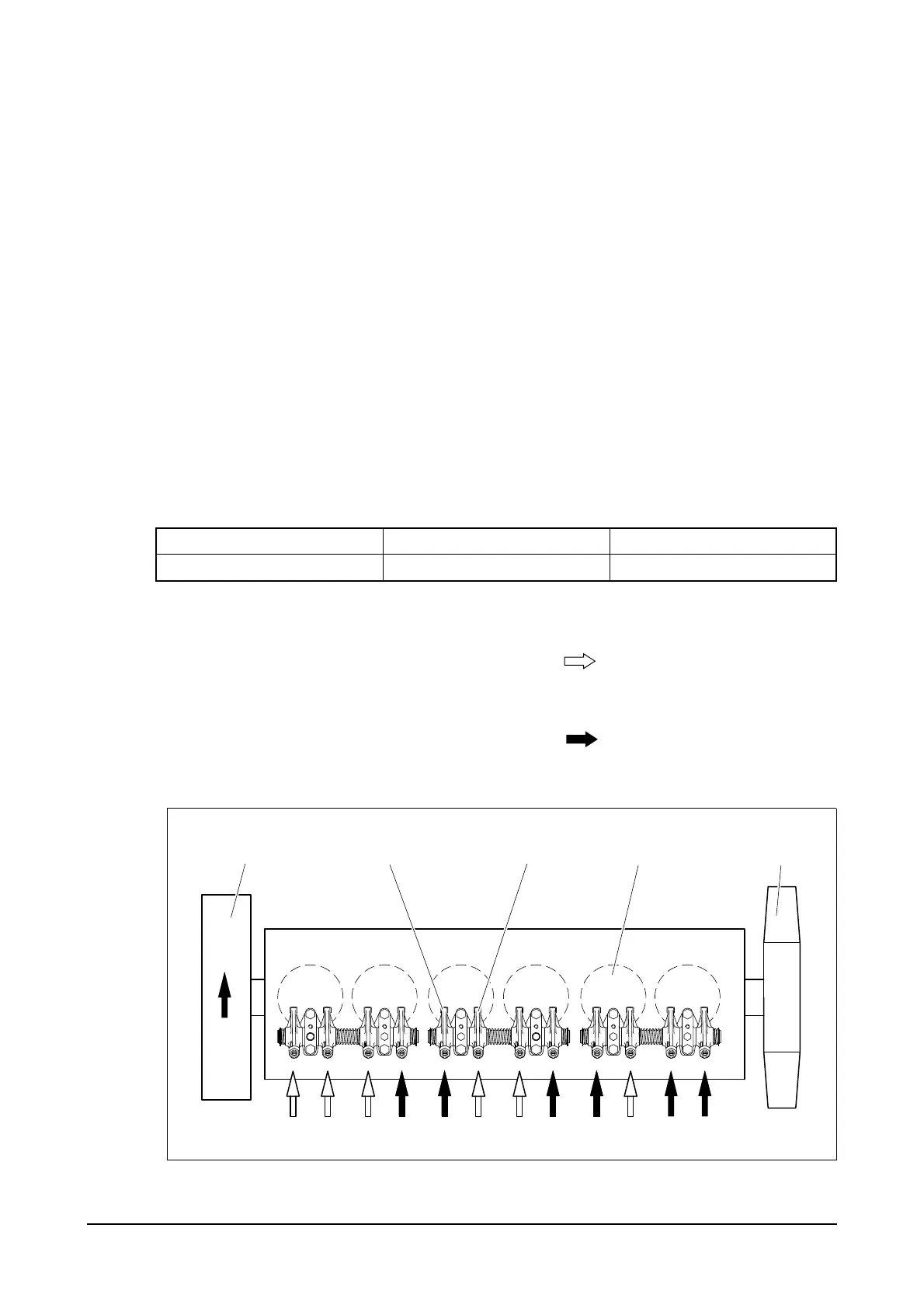

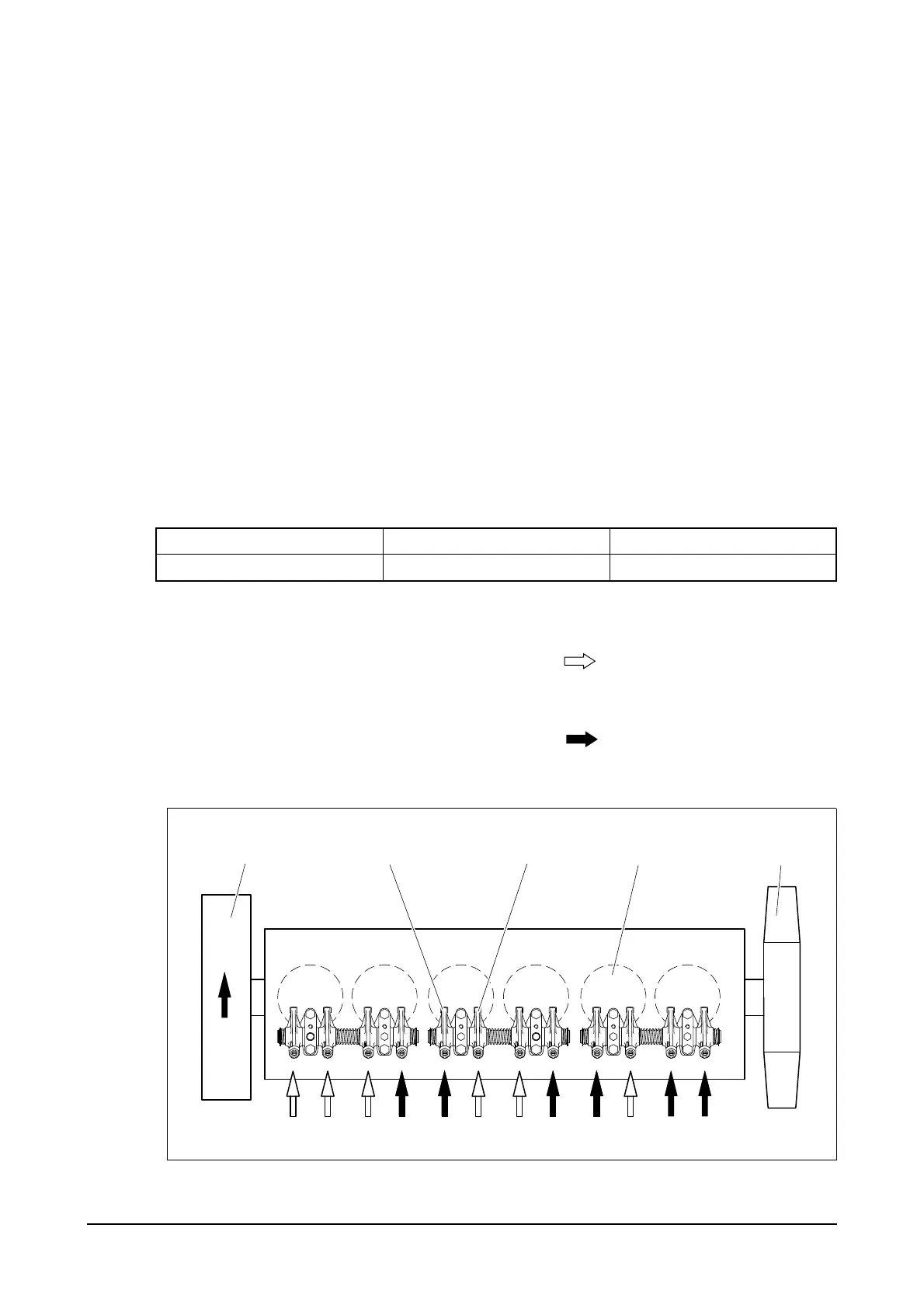

Rotate the crankshaft to overlap the intake and the exhaust valves of #6, then #1 cylinder become

the compression state of top dead center.

-

Therefore adjust the valve clearance corresponding to " " of lower figure. At this time there

are no force on the push rods of #1 cylinder.

-

Rotating the crankshaft by one revolution, #6 cylinder become the compression state of top dead center.

-

Thereafter adjust the valve clearances corresponding to " " of lower figure.

-

After reinsuring the valve clearances, retighten if necessary.

4) No. 1 Cylinder is located at the side where flywheel was installed.

Model Intake Valve Exhaust Valve

GL08K 0.3 mm 0.3 mm

12 3 4 56

EA9O5005

Flywheel Intake valve Exhaust valve Cylinder no. Cooling fan

Loading...

Loading...