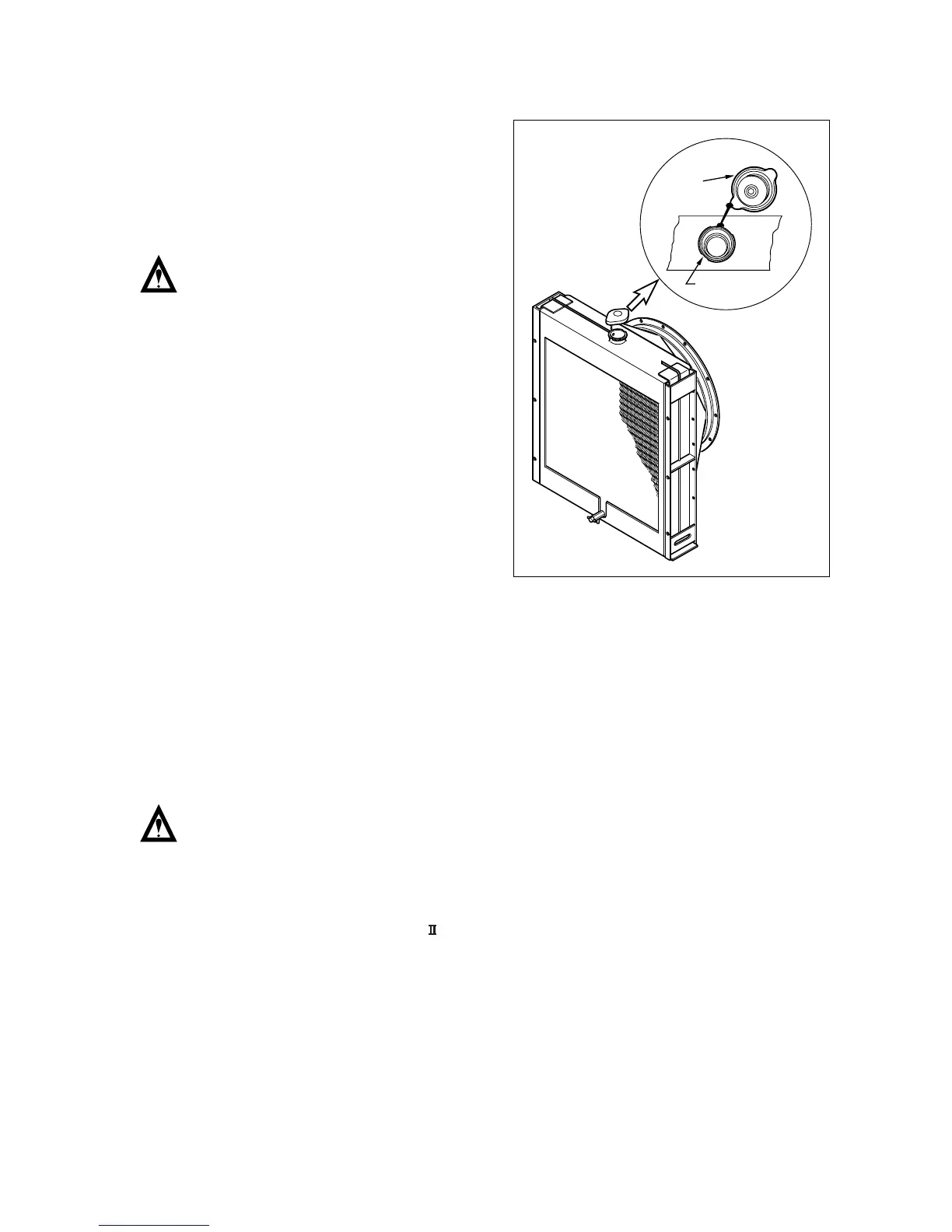

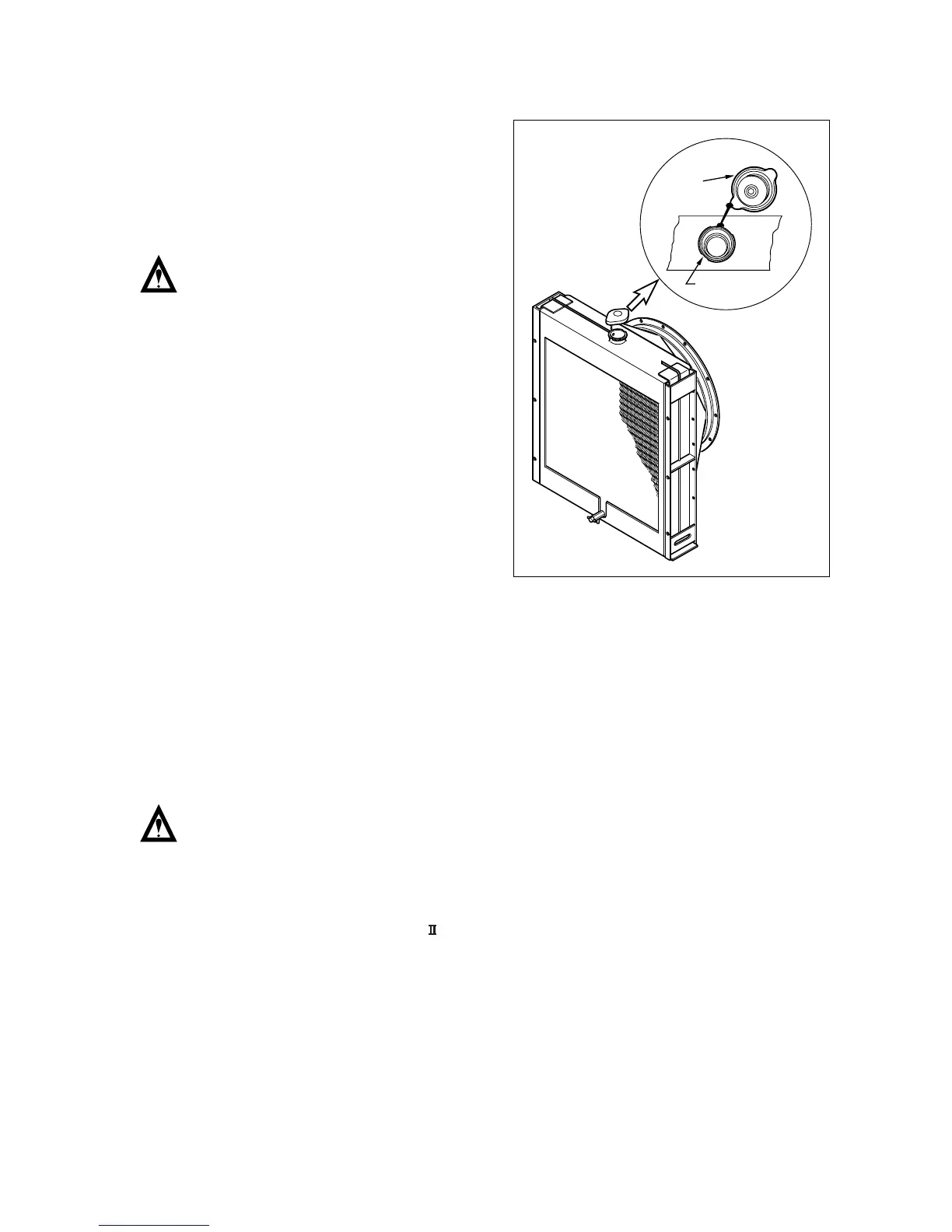

3.8.1. Coolant pressure cap

Check the pressure valve opening pressure

using a expansion tank cap tester. Replace

the filler cap assembly if the measured valve

does not reach the specified limit. (pressure

valve opening pressure : 0.9 kg/cm

2

)

Note : Because it is dangerous to open

the pressure cap quickly when

coolant is hot, after lowering the

inside pressure of the tank by

slow-opening at first open it fully.

3.8.2. Cooling water

¥

Regarding the cooling water that is to be used for engine, the soft water not the hard water

must be used.

¥

The engine cooling water can be used diluting it with antifreezing solution 40% and the addi-

tive for rust prevention (DCA4) 3 ~ 5 %.

¥

The density of above solution and additive must be inspected every 500 hours to maintain it

properly.

Note : The proper density control of antifreezing solution and rust preventing additive will

be able to prevent the rusting effectively and maintain the stable quality of engine.

For the improper control might give the fatal damage to the cooling water pump and

cylinder liners, detail care is needed.

¥

Since DE12T , P126TI and P126TI- cylinder liner is dry type, particularly the cooling water

control should be applied thoroughly.

¥

The density of antifreezing solution and additive for rust prevention is able to be confirmed by

the cooling water test kit. (Fleetguard CC2602M)

¥

How to use the cooling water test kit

1) When the cooling water temp. of engine is in the range of 10 ~ 55

¡

C, loosen the plug for

cooling water discharge and fill the plastic cup about a half.

- 18 -

Loading...

Loading...