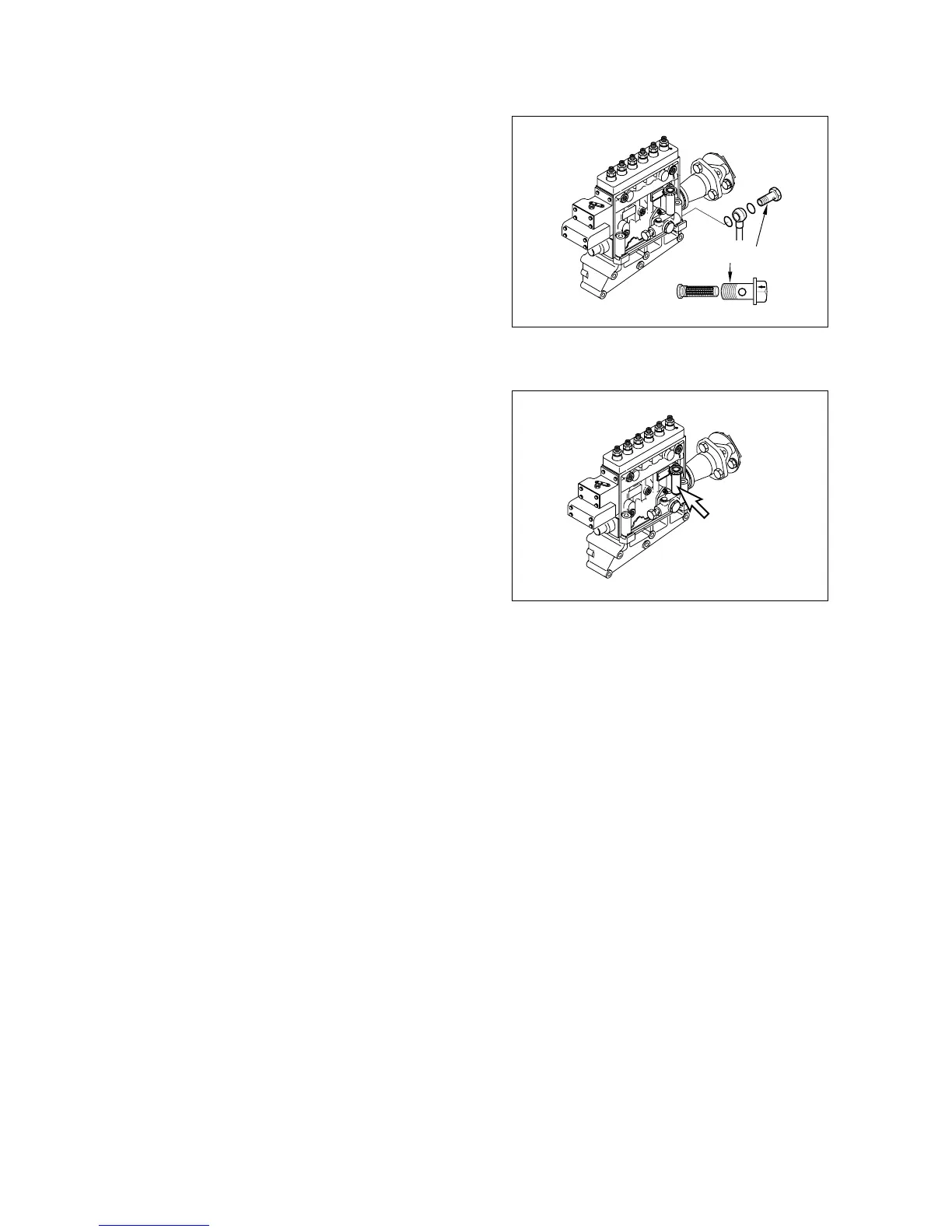

5.5.5. Priming pump strainer cleaning

Clean the priming pump strainer every 200

operation hours.

The strainer is incorporated in the priming

pump inlet side joint bolt.

Clean the strainer with the compressed air

and rinse it in the fuel oil.

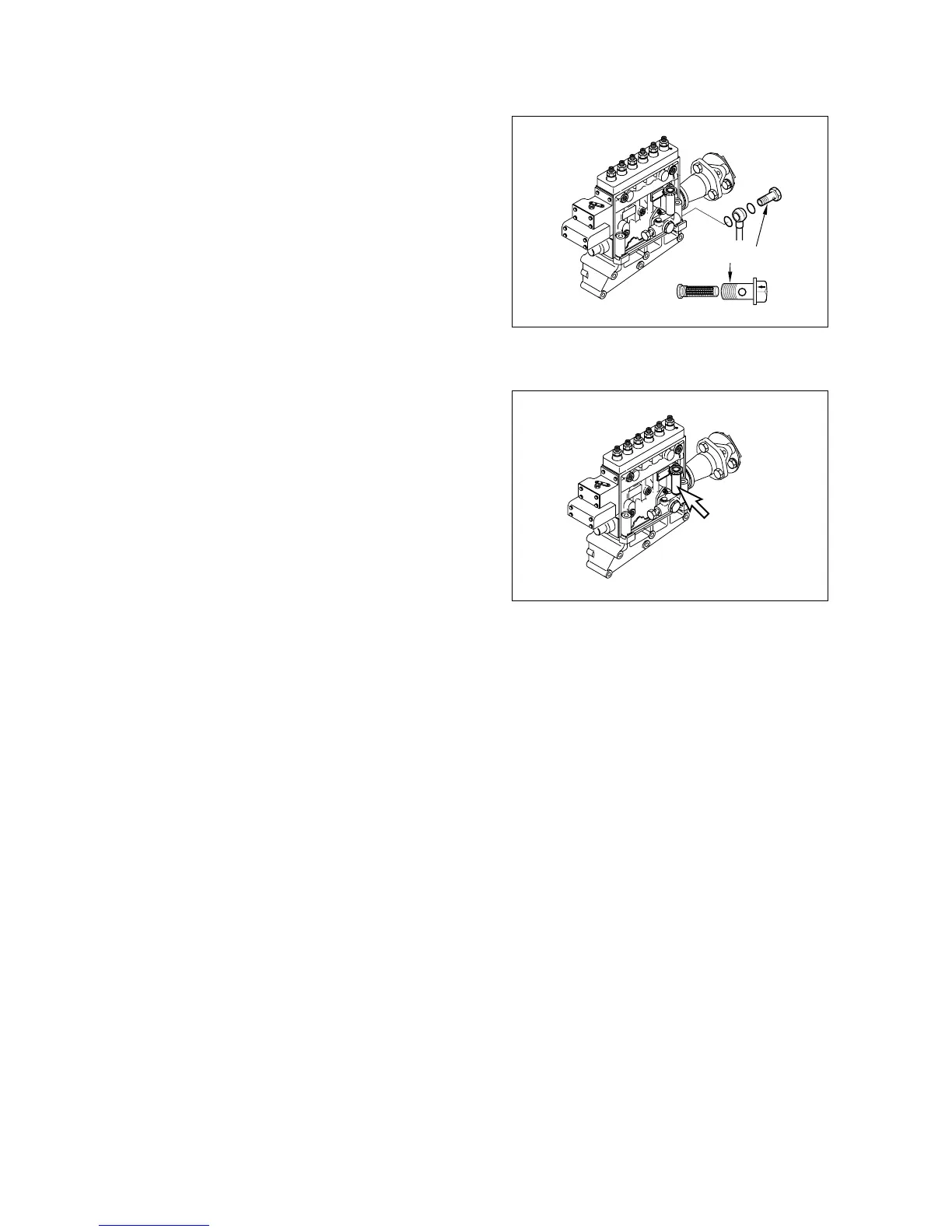

5.5.6. Bleeding the fuel system

Whenever fuel filter is changed or the

engine is stopped by cause of the fuel lack,

the air of fuel line must be removed as fol-

lows.

Bleed the fuel by manually operating the

priming pump with fuel filter outlet joint bolt

and injection pump bleeder screw loosened.

¥

Press the feed pump cap repetitively until

the fuel without bubbles overflows from

the bleeding plug screw.

¥

After the whole air is pulled out, close the

plug screws of the filter and the pump.

¥

Confirm the resistance of fuel delivery by repetition pressing of the feed pump cap, Pressure

and turn the priming pump cap simultaneously to close it.

5.5.7. Injection pump

¥

Check the fuel injection pump housing for cracks or breaks, and replace if damaged.

¥

Check and see if the lead seal for idling control and speed control levers have not been

removed.

¥

No alterations must be made to the injection pump. If the lead seal is damaged the warranty

on the engine will become null and void.

¥

We strongly recommended that any faults developing in the injection pump should be taken

care of by authorized specialist personnel.

- 37 -

Loading...

Loading...