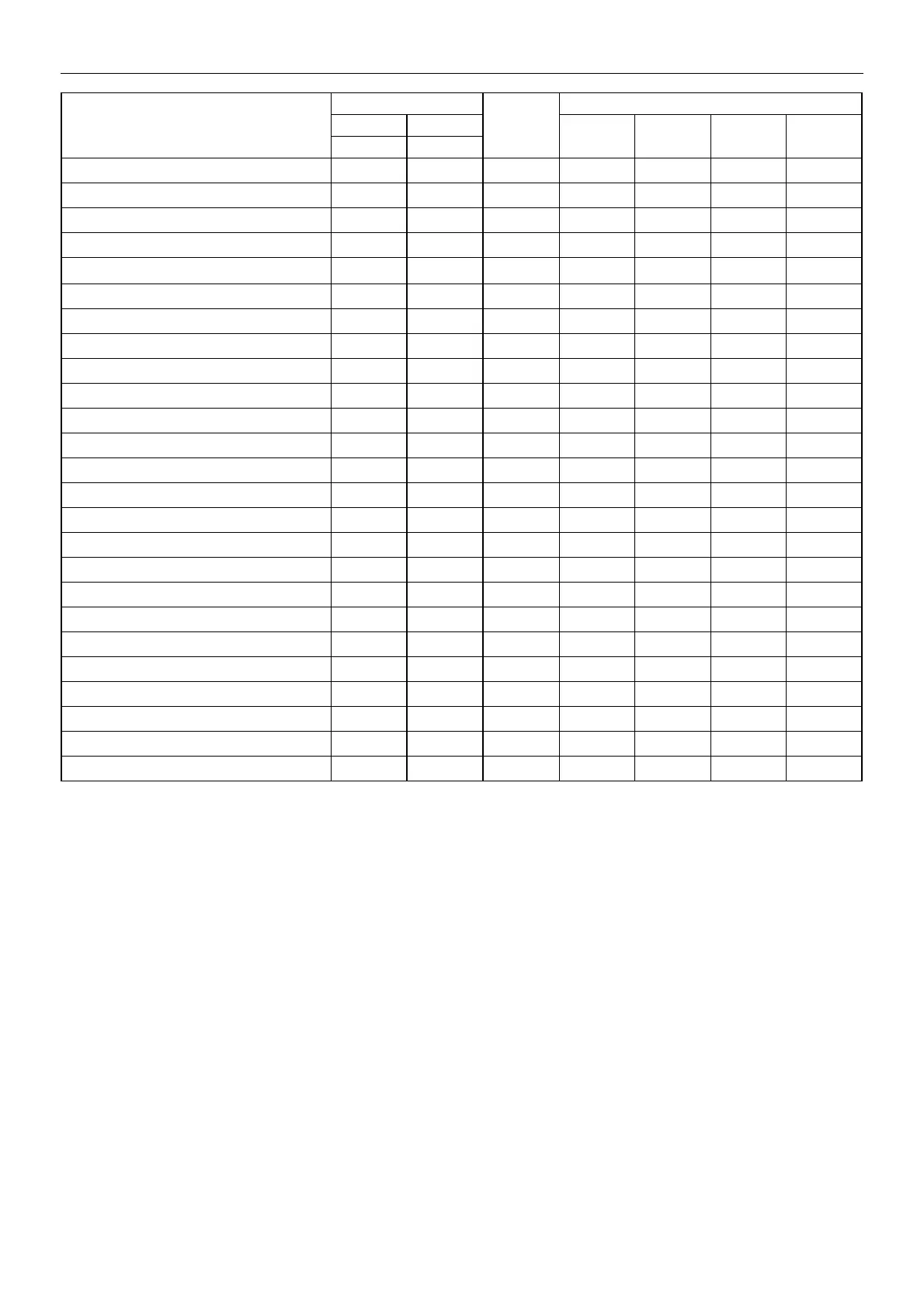

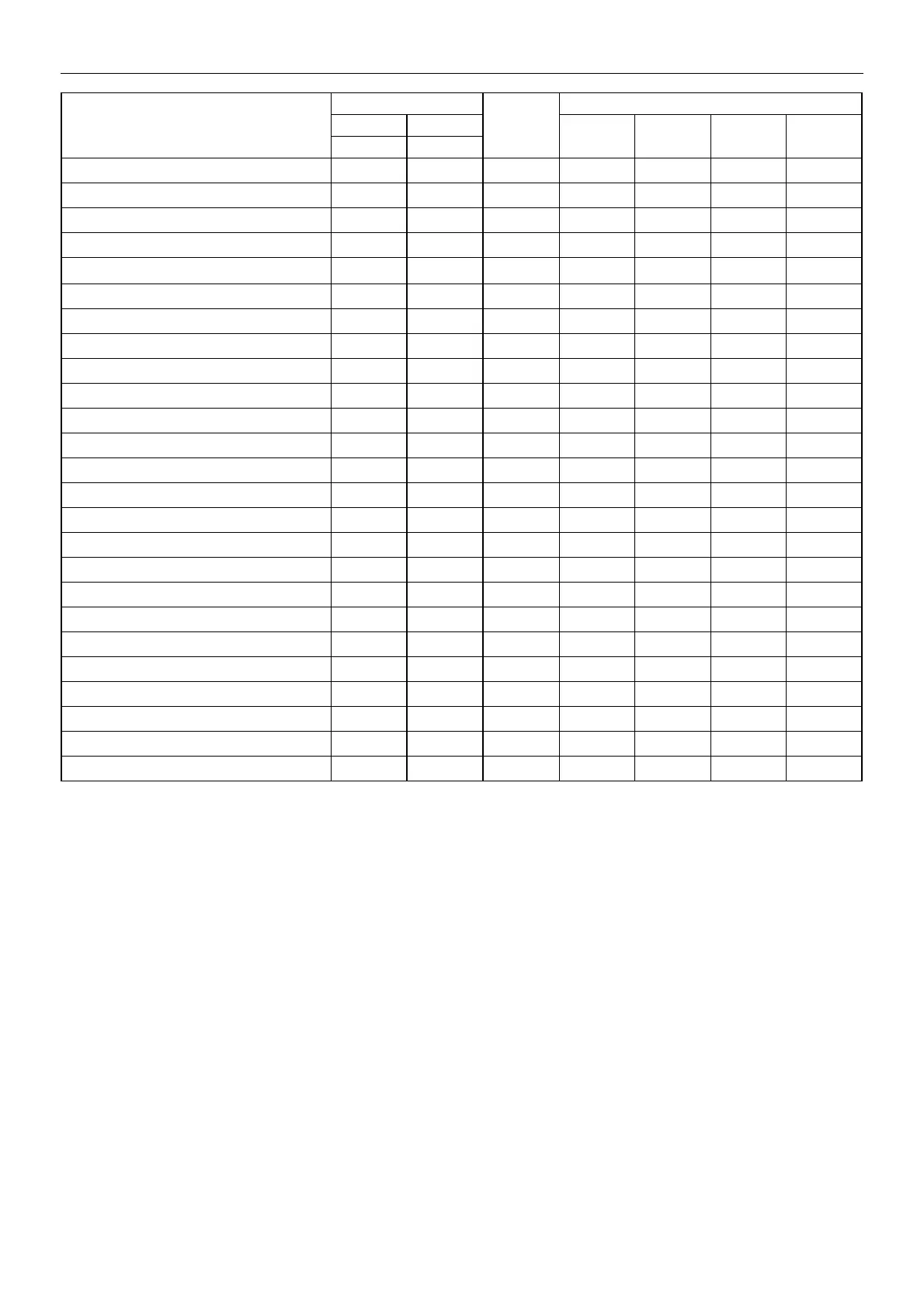

MAINTENANCE 25

7/20, P65

Initial. Monthly / Hours

km (miles) Hours

Daily 1/- 3/250 6/500 12/1,000

850 (500) 50

*Fuel/Water Separator Element

R

Compressor Oil Filter Element

R

Compressor Oil

R

Engine Oil Change

R -/R

Engine Oil Filter

R

-/R

*Water Pump Grease.

R

*Wheels (Bearings, Seals, etc.)

C

*Engine Coolant

C

Fuel Filter Element

-/R

*Injection Nozzle Check

C

Shutdown Switch Settings

T

Scavenger Orifice & Related Parts

C

Oil Separator Element

R

*Feed Pump Strainer Cleaning

. C

Coolant Replacement

R

*Valve Clearance Check

C

Lights (running, brake, & turn)

CBT

Pintle Eye Bolts

CBT

*Brakes

C C

*

Brake linkage

C

Emergency stop

T

Fasteners

C

Running gear linkage

G

Safety valve

C

Running gear bolts(1)

C

*Disregard if not appropriate for this particular machine.

(1)

or 3000 miles/5000km whichever is the sooner

(2)

or as defined by local or national legislation

C

= Check (adjust, clean or replace as necessary)

CBT

= Check before towing.

CR

= Check and report

D

= Drain

G

= Grease

R

= Replace

T

= Test

W I

= or when indicated if earlier.

Refer to specific sections of the operator’s manual for more

information.

Loading...

Loading...