CONTACT US AT www.DRpower.com 13

Chapter 4: Maintaining The DR STUMP GRINDER

Regular maintenance is the way to ensure the best performance and long life of your machine. Please refer to this manual and the

engine manufacturer's owner's manual for maintenance procedures. Service intervals listed in the checklist below supersede

those listed in the engine manufacturer's owner's manual.

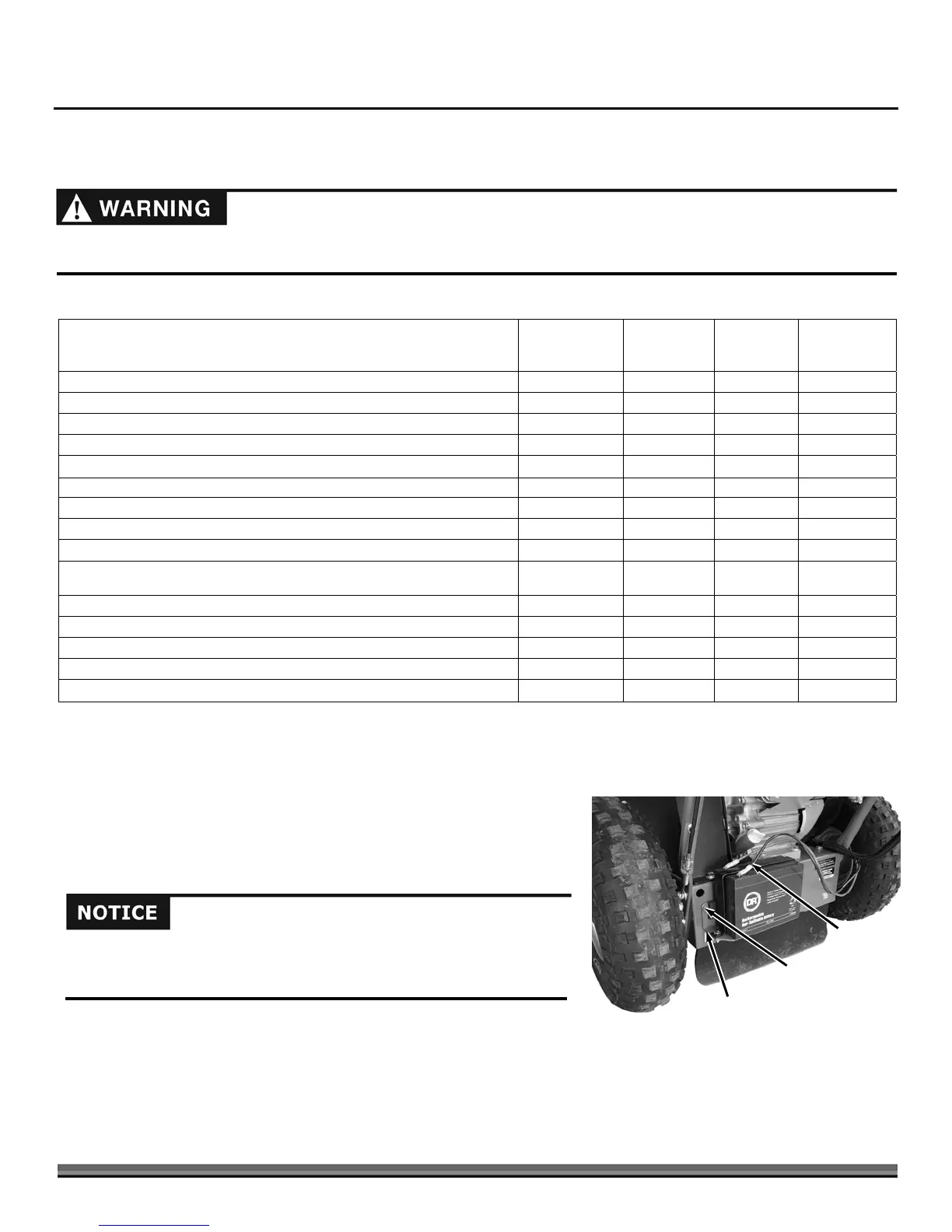

Regular Maintenance Checklist

PROCEDURE BEFORE

EACH USE

E

VERY 25

HOURS

E

VERY 60

HOURS

E

VERY 100

HOURS

Check En

ine Oil Level

Check General E

ui

ment Condition

Check Cuttin

Teeth

are the

dull or dama

ed

Clean En

ine Exterior & Coolin

Fins

Remove debris wrapped around Cutter Head for Bearing protection.

Check Tire Pressure

Re

lace Belt if stretched or worn

Clean Air Filte

Lubricate Cables

SAE 30 Oil

Change Engine Oil

1

st

time 5

hours

Re

lace Cuttin

Teeth

or sooner if dull or dama

ed

Check Cutter Head when Teeth are re

laced

Re

lace Cutter Head

order kit # 30506

Re

lace S

ark Plu

Replace Air Filter

Removing and Replacing the Engine Oil

Tools and Supplies Needed:

10mm (Premier) or 12mm (Pro and Pro-XL) Wrench

1/2" Wrench (electric start only)

Rags and approved Container (for waste oil)

Small funnel

Engine Oil (see your Engine Manual for Oil specifications)

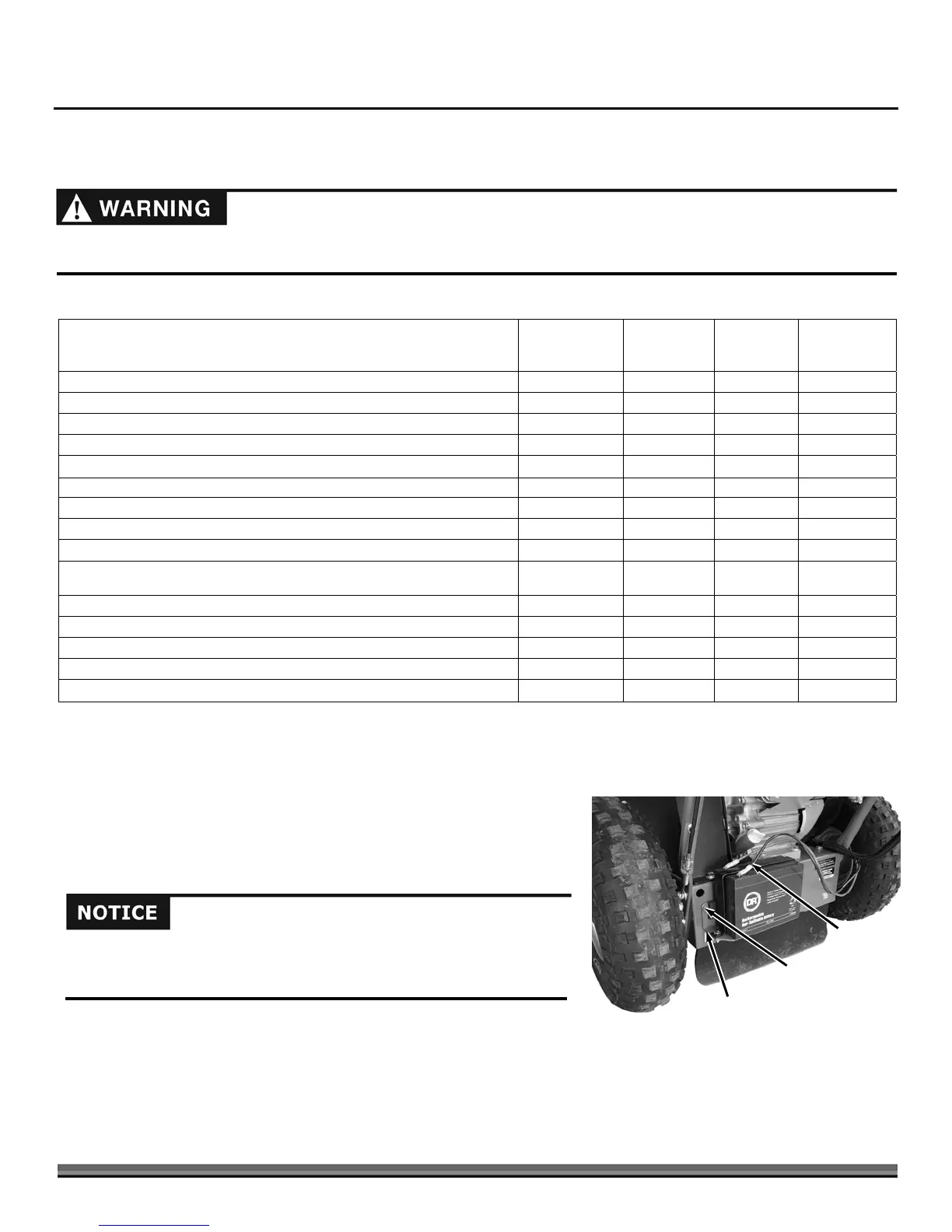

1. For Electric Start machines you will first need to disconnect the Battery

Terminals and remove the Battery Bracket by removing the two Locknuts

from the Bracket Studs with a 1/2" Wrench (leave Battery attached to

Bracket) (Figure 16).

Battery Bracket

Figure 16

Locknuts

inside Frame

Battery

Terminals

Before performing any maintenance procedure or inspection, stop the engine, wait five (5) minutes to allow all parts to cool.

Disconnect the spark plug wire, keeping it away from the spark plug. Disconnect the Battery Terminals (Electric start only).

The Frame and Engine must be level to get an accurate reading when

adjusting the oil level. Use blocks to adjust the height of the cutting head to

level the Frame.

Loading...

Loading...