Plus and PSS Series - Lung Demand Valve

tm 1285.001 - August 2001

5:4

3. Rinsing and Drying

Remove cleaning and disinfecting solutions by rinsing in clean running

water, followed by drying.

Do Not exceed a temperature of 60 degrees Celsius when drying

components. Immediately remove from the drying cabinet when dry.

Never exceed a period of 30 minutes.

5.3.2 Cleaning and Disinfecting

External cleaning of the lung demand valve may be carried out as

required using a cloth dampened in the above cleaning solution.

Important Note: When cleaning using a dampened cloth, take care to prevent

any fluid residue entering the demand valve.

When however the user consides it necessary to internally disinfect the

lung demand valve then these instructions should be followed:

Note: 1

Detach demand valves (fitted with male coupling) from the female

coupling of the medium pressure hose of C.A.B.E.

Note: 2

If necessary, demand valves attached directly to the reducer should be

removed at the hose connection to the reducer. For details of removal

refer to the appropriate section of the relevant C.A.B.E. Training Manual.

Tools Required

Plate Spanner R26817

Silicone Spray - SILKOSPRAY® (500ml) 1563343

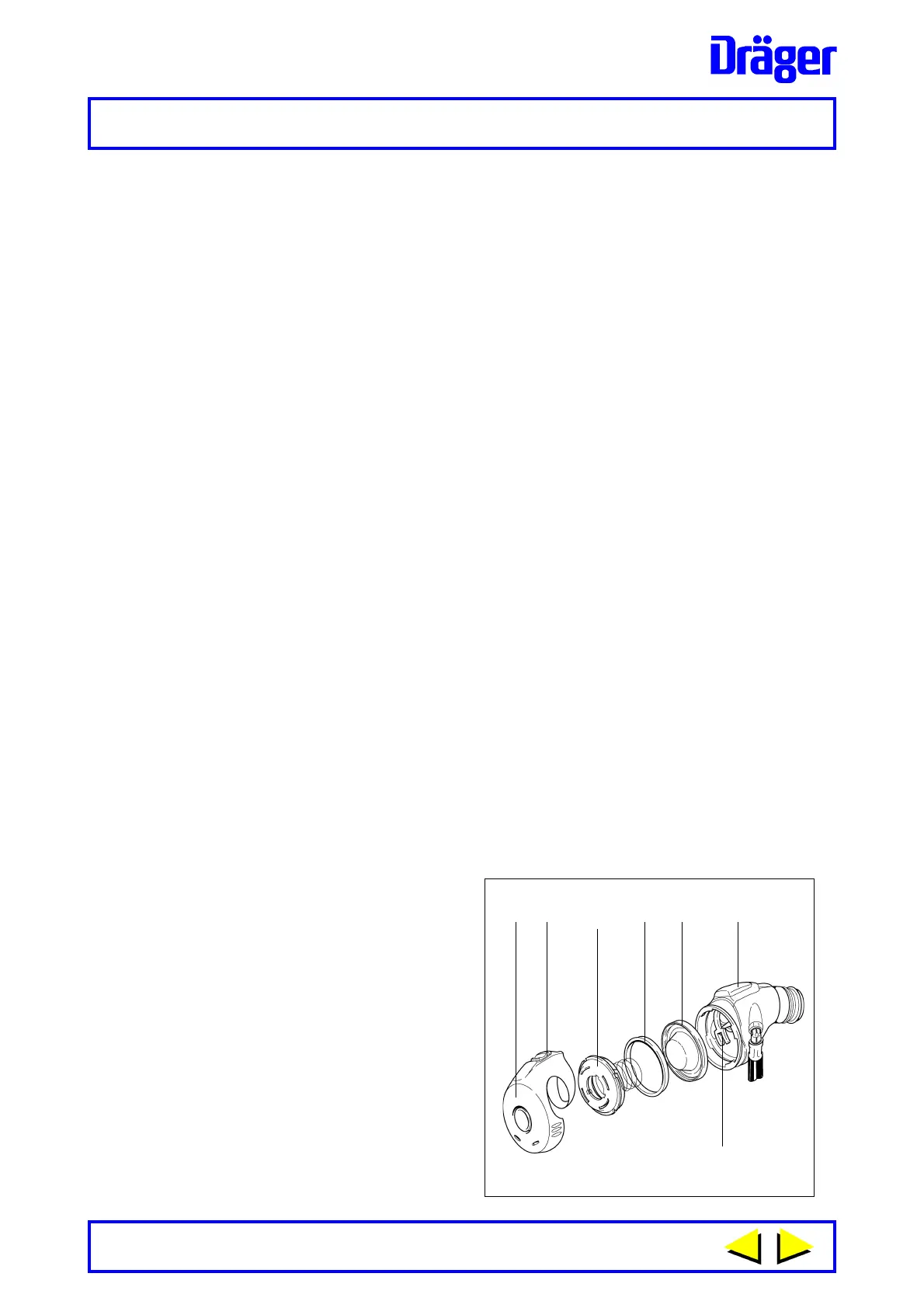

Refer to Figure 1 – (Type A Illustrated.)

1 If required, detach demand valve from equipment.

2 Fold rubber cover (1) from front of lung demand valve. Using plate

spanner inserted into radial slots of bayonet cap, turn bayonet cap (2)

12

3

4

5

6

Fig. 1

0584

6

counter-clockwise and remove

cap from body of demand

valve.

Note:

Types A and AE - the positive

pressure spring remains attached

to the bayonet cap.

Do Not

remove spring. Take care not to

stretch or distort the spring.

3 Using the thumb and forefinger

carefully grip the centre plate of

the diaphragm (3), tilt centre

plate and lift the diaphragm from

the body of the lung demand

valve. Remove slip ring (4).

Loading...

Loading...