16

www.DrillDoctor.com

Determining if Replacing the Diamond

Sharpening Wheel is Required

You can double the life of the diamond sharpening wheel by

reversing it before you replace it. The sharpening wheel supplied

with the Drill Doctor

®

is designed to give you long and trouble

free service, with an average of more than 200 sharpenings for

3/32" to 1/2" drill bits.

The diamond wheel may need to be changed if:

1. Sharpened drill bits burn or turn blue no matter how fast

or slow you rotate the chuck.

2. When touching the sharpening wheel (with the machine

unplugged), the lower portion feels too smooth

(nonabrasive).

3. When sharpening the drill bit, it takes too many half-

rotations to sharpen.

Contact the store or dealer where you purchased the Drill

Doctor,

®

or contact Drill Doctor

®

directly, to purchase a

replacement sharpening wheel.

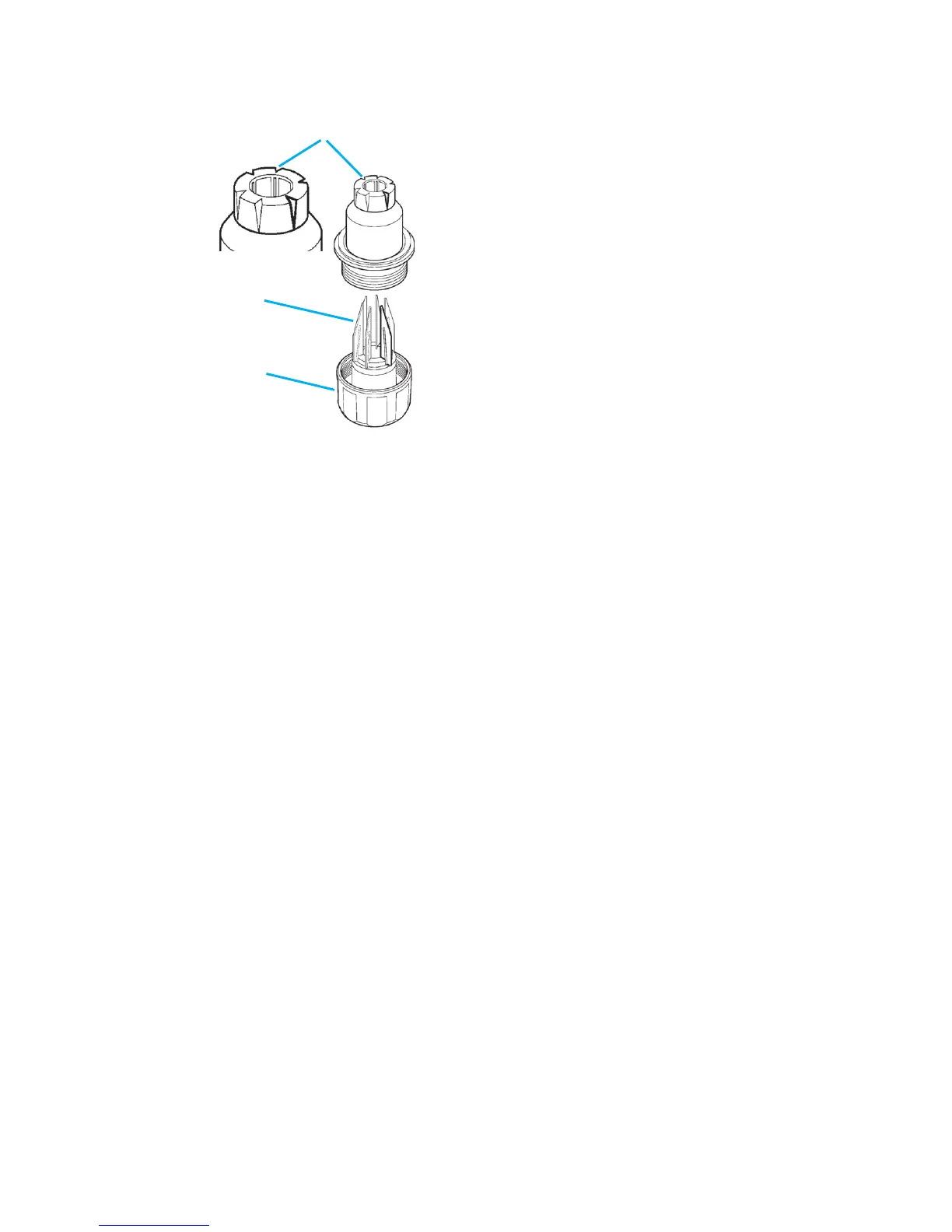

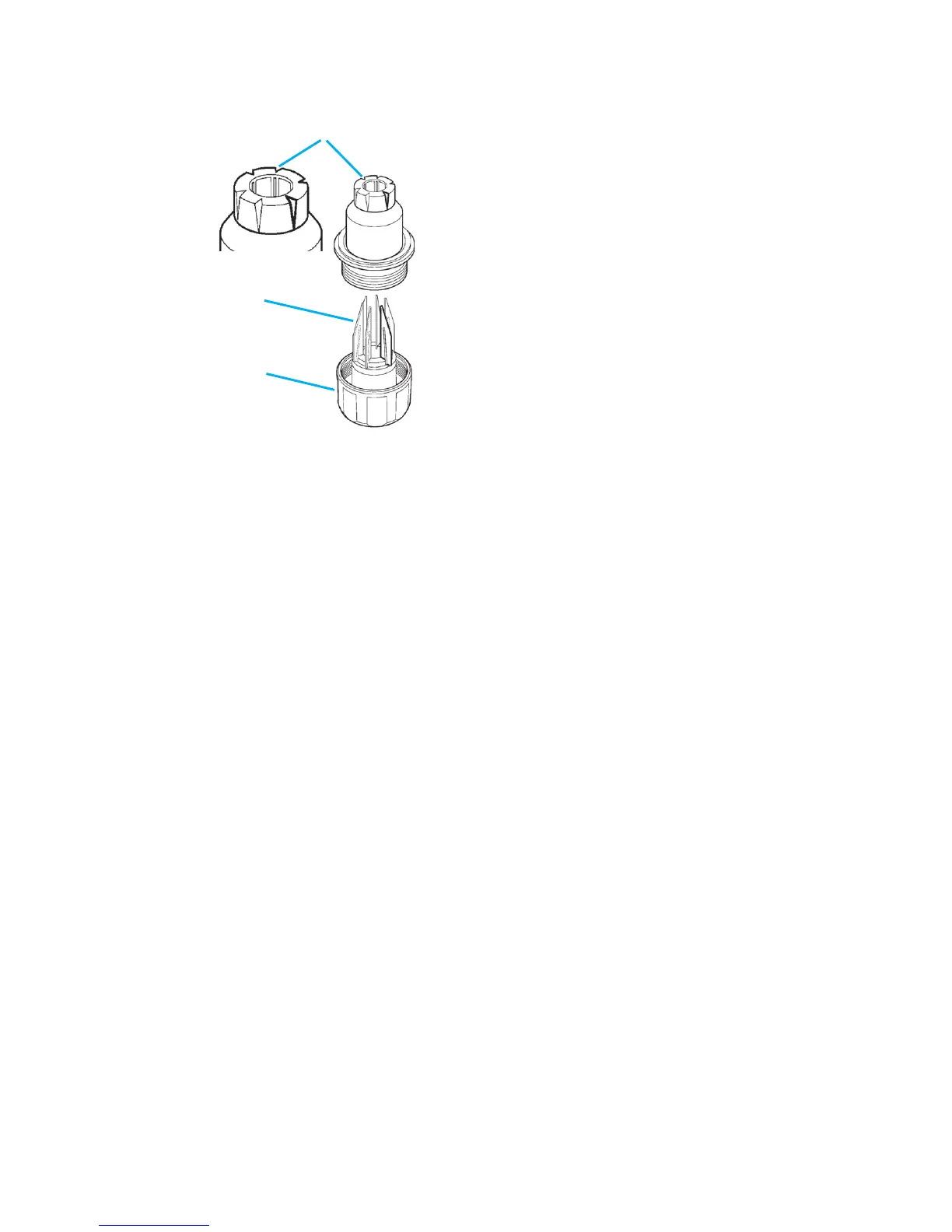

Jaw Alignment

Grooves

Jaws

Chuck

Knob

Cleaning the Chuck

With compressed air, blow out the

Chuck from the Knob end. After 20 to

25 sharpenings, you will need to

disassemble the Chuck for cleaning:

• Keep the Chuck upright (vertical)

and remove the Chuck Knob.

• Do not remove the springs or Jaws.

• Use a small brush or rag to remove

all grinding particles.

• Reassemble with all of the Jaws in

their respective grooves. If some

Jaws do not slip into their grooves

on the inside of the Chuck, reach

through the hole in the bottom of

the Chuck Knob (or use a paper clip

or small bit) and align them.

Loading...

Loading...