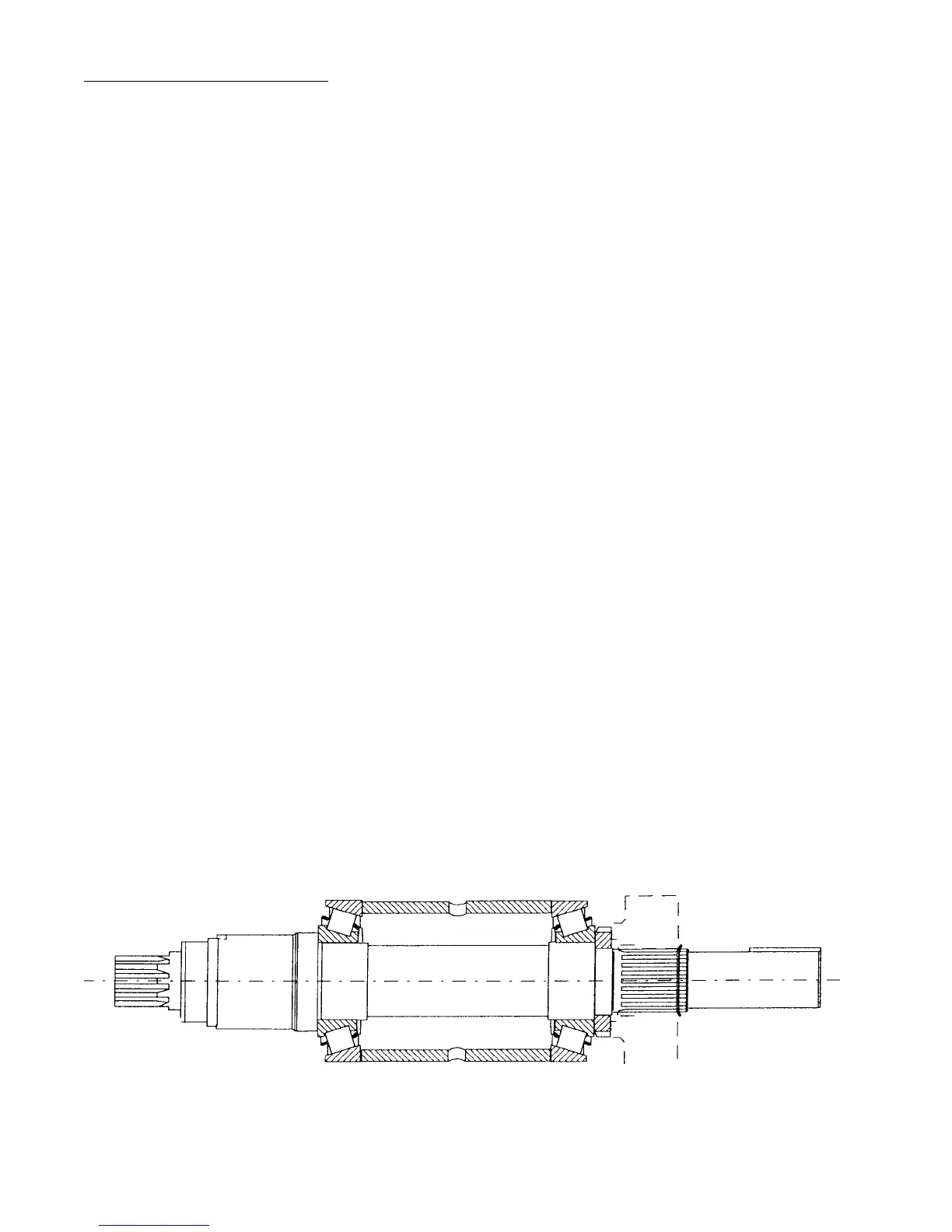

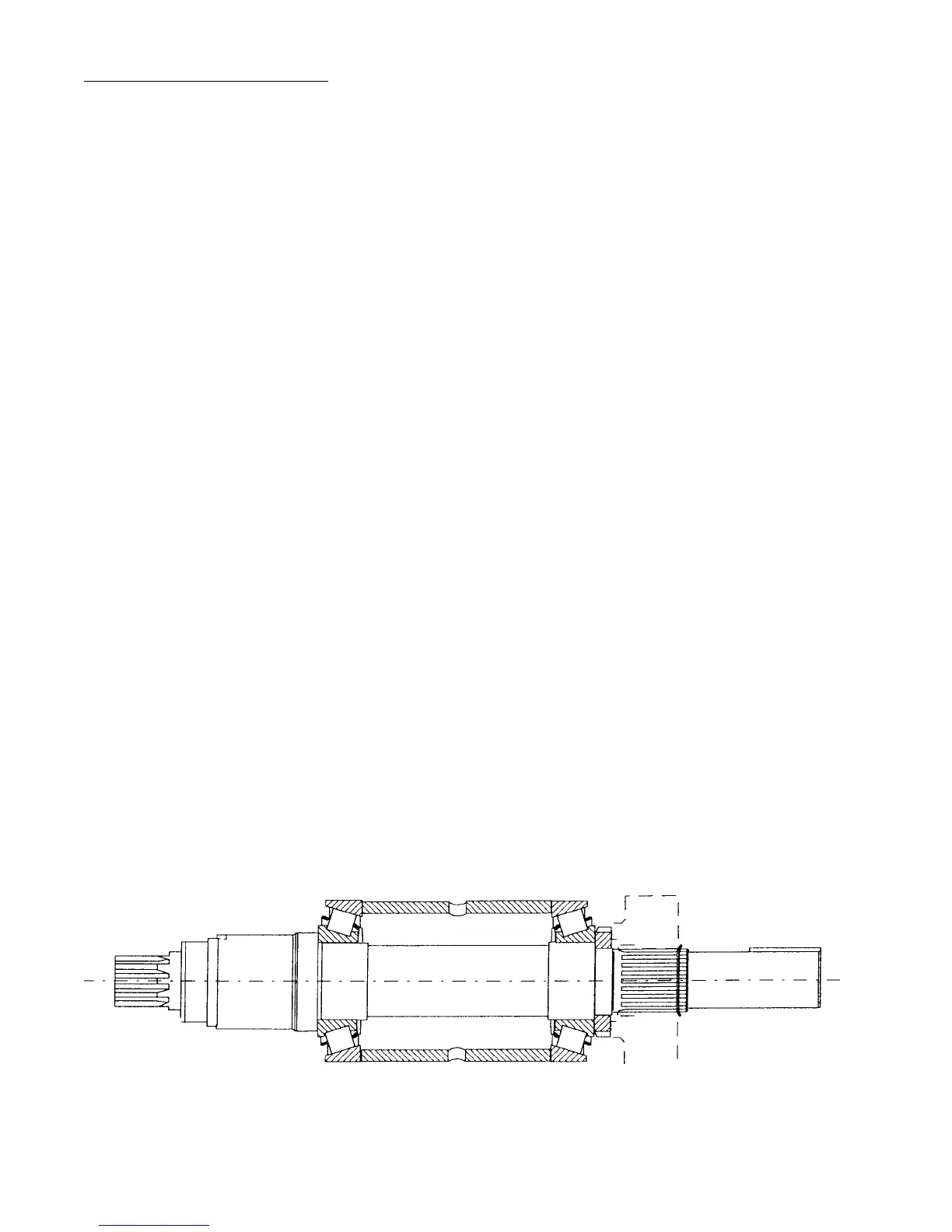

Bearing Assembly

1. For easier assembly it is advisable that the shaft should first be mounted vertically

into a vise, with the rotor spline in the downwards position. A suitable anti-seize

compound should be applied to the bearing diameters.

2. The front bearing inner assembly should be heated to 120 degress C using either

an induction heater or an oil bath. Ensure that all necessary safety precautions are

taken while heating bearings.

3. The bearing should be carefully placed over the shaft with the largest diameter of

the taper downwards. Ensure that a positive fit is achieved on the front bearing

diameter against the shaft shoulder.

4. Fit outer bearing to front assembly.

5. Place the long bearing spacer over the shaft so that it locates against the outer

bearing face of the bearing just fitted.

6. The rear bearing should be heated as in 2. With the largest diameter of the inner

cones taper upwards, the bearing can be fitted.

7. Allow bearings to cool before proceeding.

8. Locate shaft horizontally in vice.

9. The shaft locking nut thread should now be coated with permabond grade 145

sealant or equivalent. Screw lock nut onto the shaft. Correct fitting is achieved

when the bearing lock nut is tightened up, while both bearings and spacer are

continously rotated, until the spacer can no longer be moved by finger pressure

alone.

Fig. 6

Page 14

Loading...

Loading...