Shafts - General

Each pump has two shafts which are housed within the gearcase. Both shafts have been

manufactured with two splines for rotor and timing gear location, In the standard pump the

'drive shaft' is easily identified as it is the longest of the two shafts, and has a keyway ma-

chined into it. This is the bottom shaft. For pumps fitted with hydraulic drive, the drive shaft

has an adaptor fitted to the timing gear, and is the top shaft. The remaining shaft is referred

to as the 'auxiliary shaft'.

Shafts - Refitting Assemblies

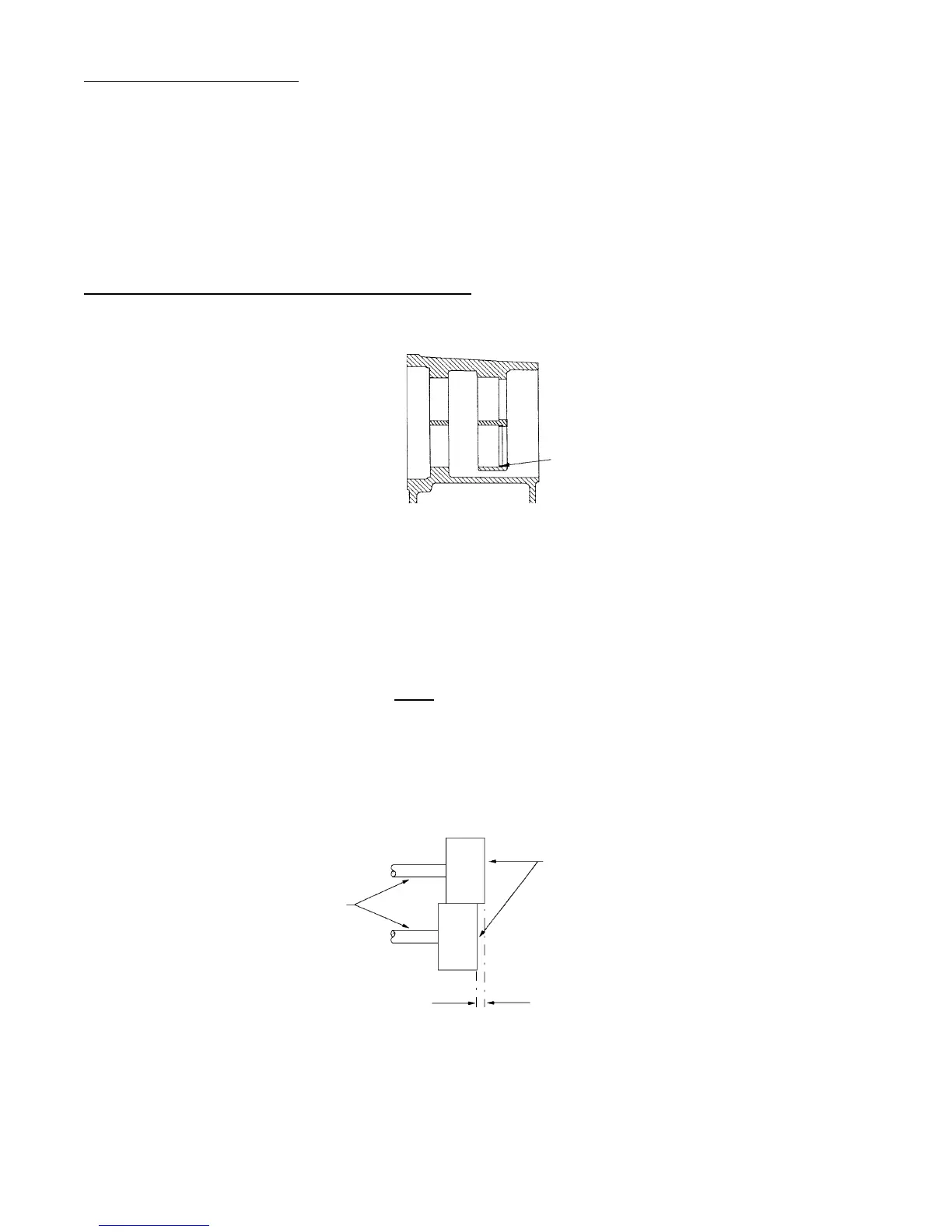

1. Locate the shaft alignment spacer into the bottom rear bearing bore of the gearcase.

Fig. 7.

2. Fit the drive shaft into the appropriate gearcase bore, which is on the same center

line as the coupled drive unit being used (standard drive - bottom, hydraulic drive -

top).

3. Fit the auxiliary shaft into the remaining bore of the gearcase.

4. The front bearing retainers can be located in position and tightened to the torque

required. Note: DO NOT USE silicon sealant at this stage.

5. Fit both rotors as detailed in Rotor Assembly section.

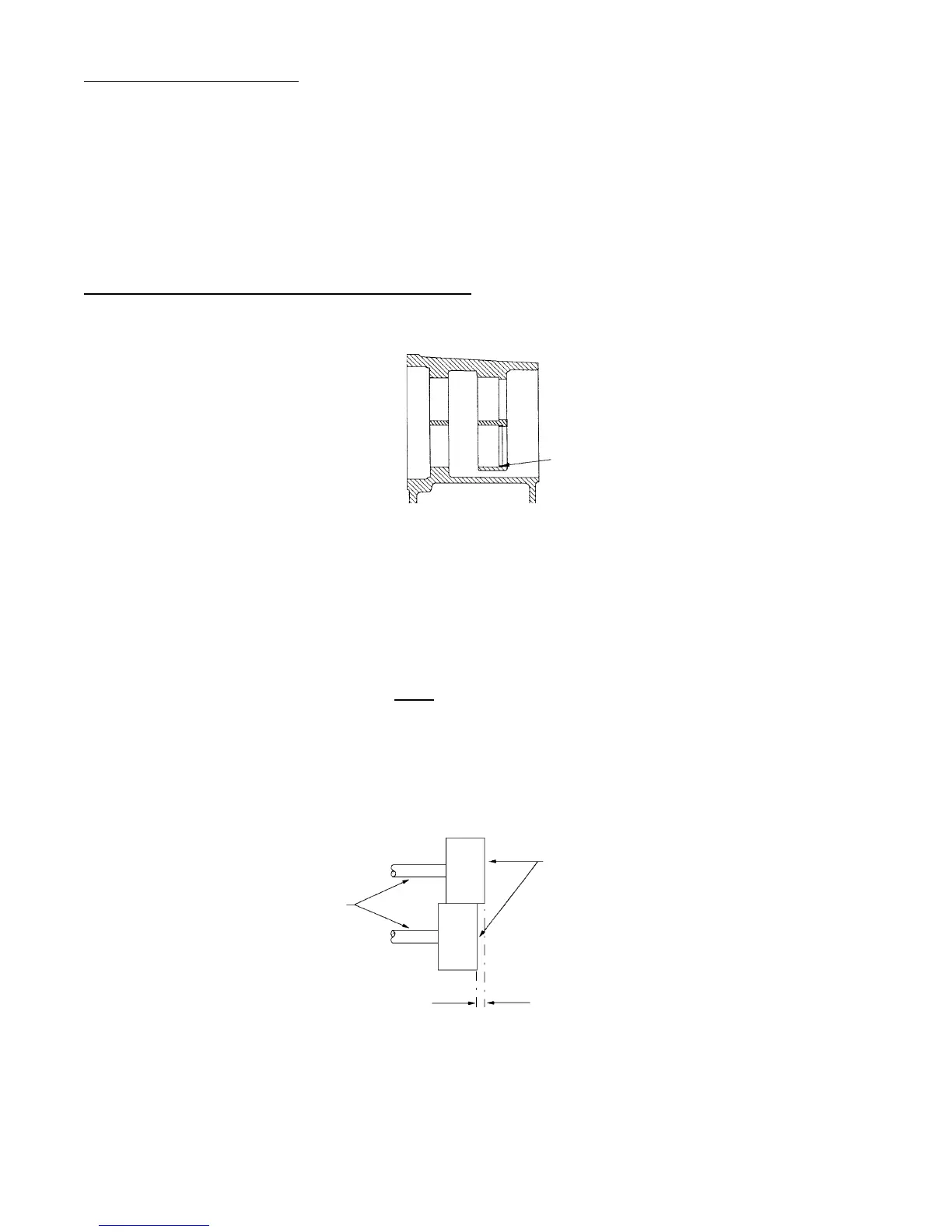

6. The difference in axial displacement should be measured using a depth micrometer.

By comparing the differences between each rotor, the axial displacement is

recorded, see Fig. 8.

7. If the axial displacement is above 0.012mm (0.0005"), the appropriate shaft should

be removed to gain access to the shaft alignment spacer. The spacer should be

ground down to give the correct axial displacement.

8. Once the correct displacement is achieved, the silicon sealant should be applied to

the seal retainers, and screws retightened to specific torque requirements.

Shaft

Alignment

Spacer

Fig. 7

Rotors

Shafts

Axial Displacement

Fig. 8

Page 15

Loading...

Loading...