Mechanical Seal - Assembly

Seal faces and seals are manufactured from brittle materials.

Care must be taken fitting when not to chip these components.

1. Lightly lubricate the 'O' ring (A) with a suitable food quality grease and locate in the

recess in the rotorcase bore.

2. Lightly grease the 'L' ring (F) and insert into the rotary seal ring (C).

3. A pin is located in the rotary seal ring (C). Carefully slide the ring over the shaft so

that the pin locates in the slot machined into the shaft.

4. Place the wave spring (D) over the static ring (E).

5. Push the static ring (E) with wave spring (D) into the flat sided bore of the rotorcase

and through the 'O' ring (A).

7. Offer the rotorcase onto the locating dowels of the gearcase, taking care not to

damage the seal against the shaft.

8. Follow the procedures for fitting the rotorcase and rotors.

Page 18

Mechanical Seal - General

Mechanical seals are precision made to provide good sealing qualities. Careful attention to

the following will prevent seal leakage:

1. Take care with seal faces when removing or refitting the

seal.

2. DO NOT place seals face down on bench. Seal faces

may easily be damaged.

3. 'O'rings and 'L' shaped elastomers should be protected

and regularly inspected.

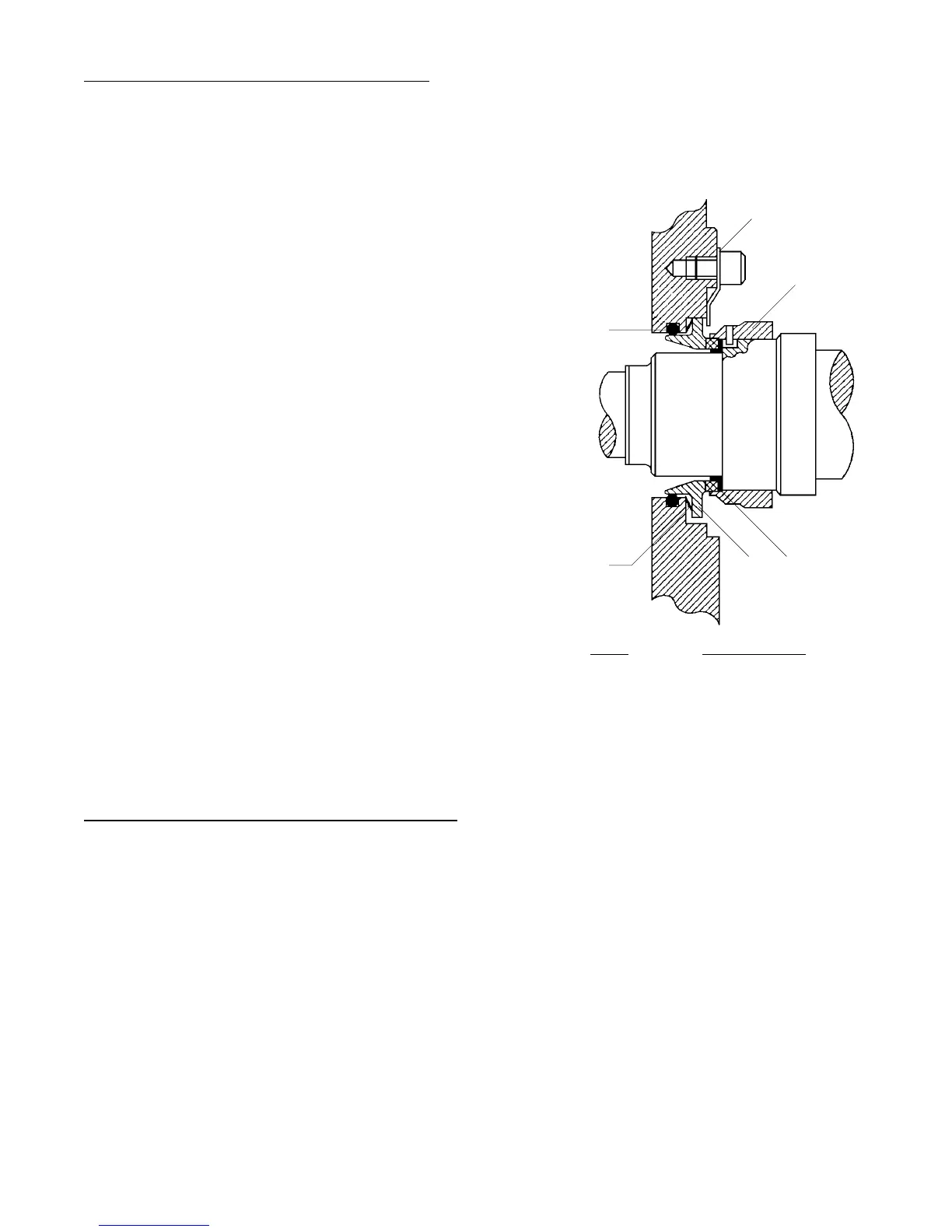

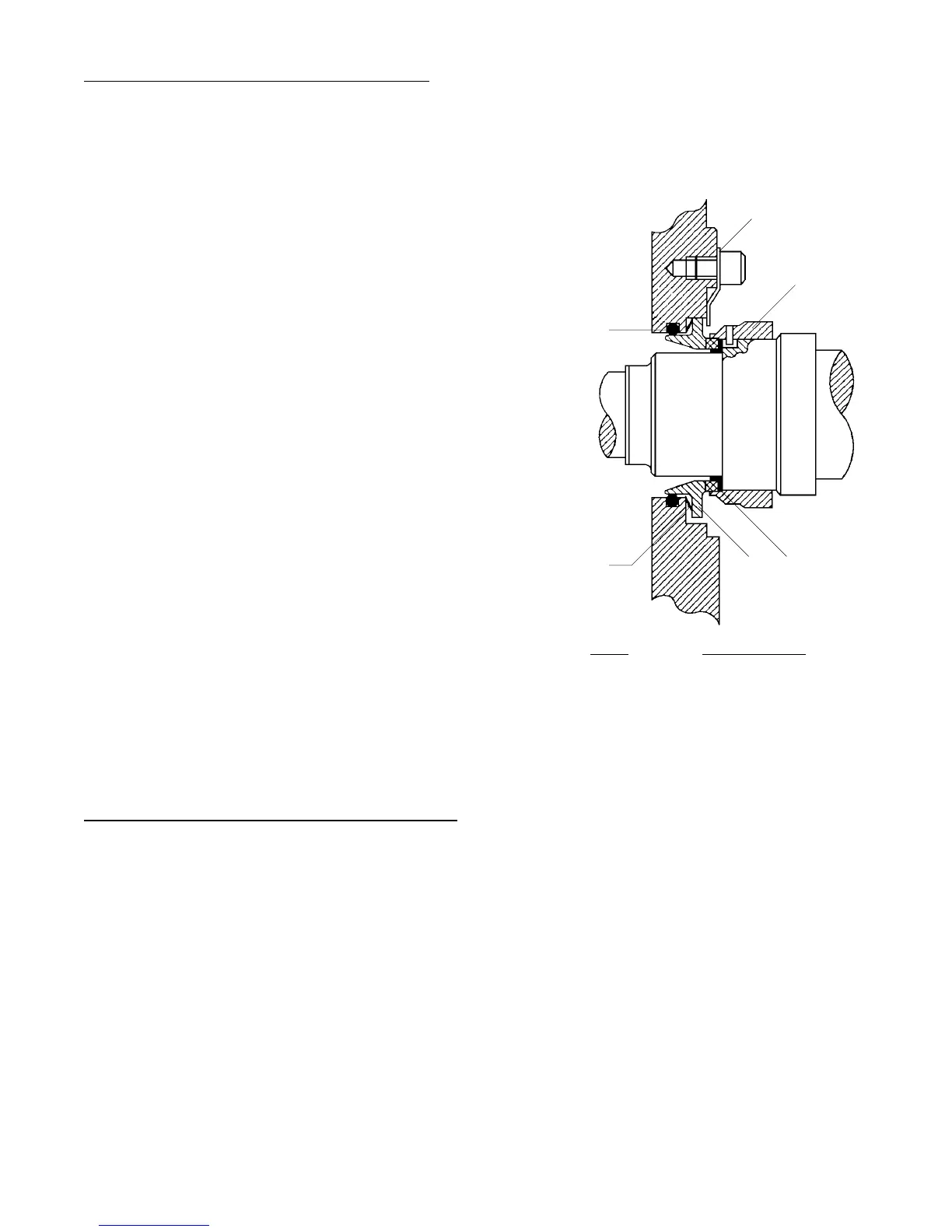

The seal consists of a rotary seal ring (C), which is driven

by the shaft by means of a pin locating in a slot on the

shaft. An 'L' shaped elastomer ring (F) seals the rotary

ring to the shaft.

A static seal ring (E), the mating seal face, sit in the flat

sided bore of the rotorcase to prevent it rotating.

Behind the static seal ring, a wave spring (D) applies a

force to maintain contact between both static and rotary

seal faces. A clip (B), held in place by a set screw, in the

rotorscase restricts axial movement of the static seal

durring assembly.

An 'O'ring (A) sits in a groove within the rotorcase bore

providing a seal onto the static seal ring.

Item Description

A 'O' ring

B Retaining Clip

C Rotary Seal Ring

D Wave Spring

E Static Seal Ring

F 'L' ring

B

C

A

DFE

Loading...

Loading...