Fitting the Rotorcase and Shims

Correct shimming is critical to avoid damaging the pump.

Take care not to damage the product seals

when sliding rotorcase over the shafts.

First ensure that the product seals are correctly fitted. If old shims are being reused, ensure

that they are replaced in their original positions. The following procedure should be adopted if

new shims are to be fitted:

1. Fit thinnest shim over rotorcase studs both top and bottom. Fit o-rings over studs.

2. Locate the four rotorcase studs into the matching gearcase holes, ensuring that

gearcase dowels locate in holes in rotorcase. The gearcase nuts should be tight

ened to th required torque, see page 21.

3. Refit the rotors as detailed in ROTOR ASSEMBLY section.

4. By measuring the back clearances with feeler gauges, any additional shimming

required may be predetermined, to bring the clearance within tolerance.

5. Additional shims should be fitted, by repeating steps 1 and 2, and clearances

rechecked. It is essential that clearances come within tolerance, so the above

should be repeated until this is achieved. Clearances should be similar for both top

and bottom of the rotorcase.

6. Refit rotorcase and tighten gearcase nuts to the required torque, see page 21.

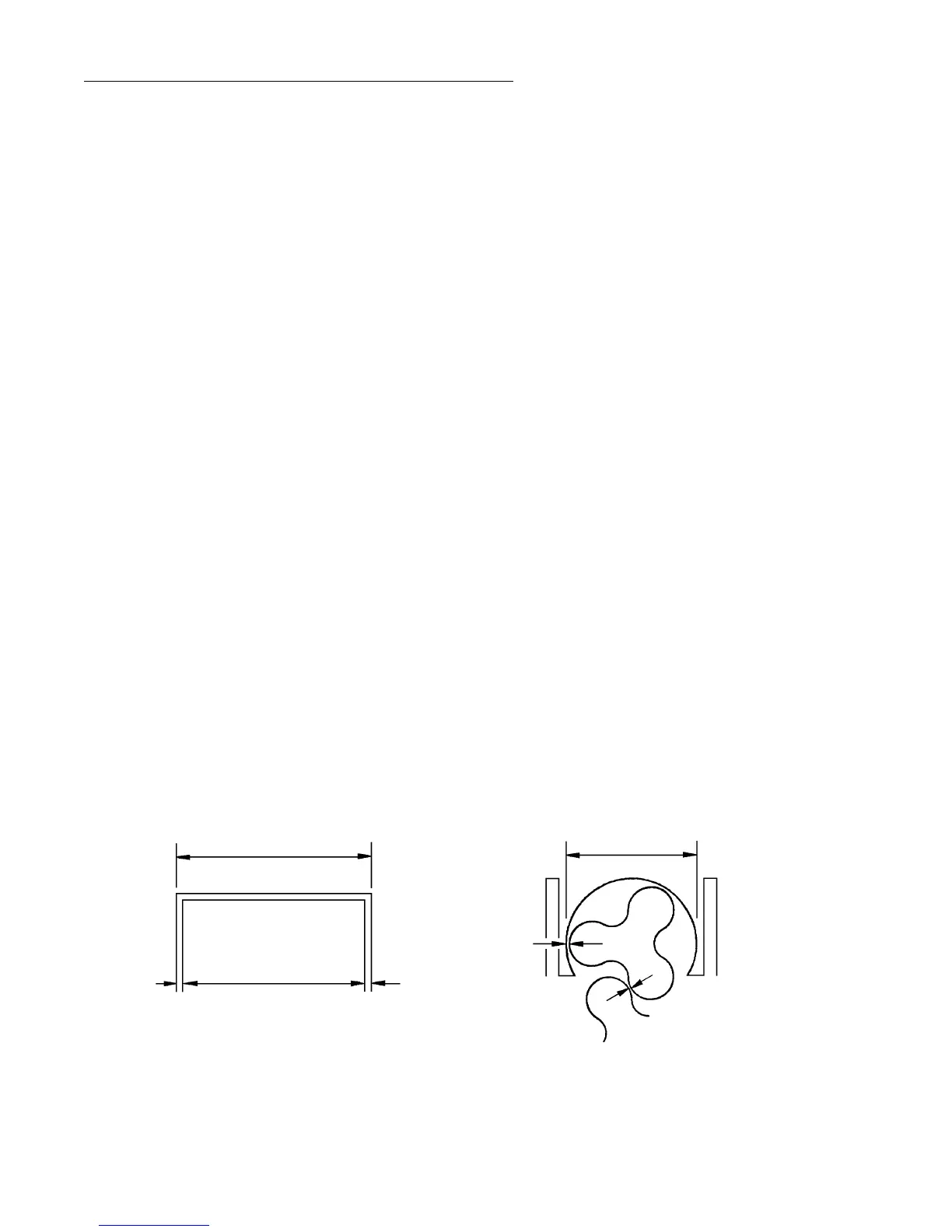

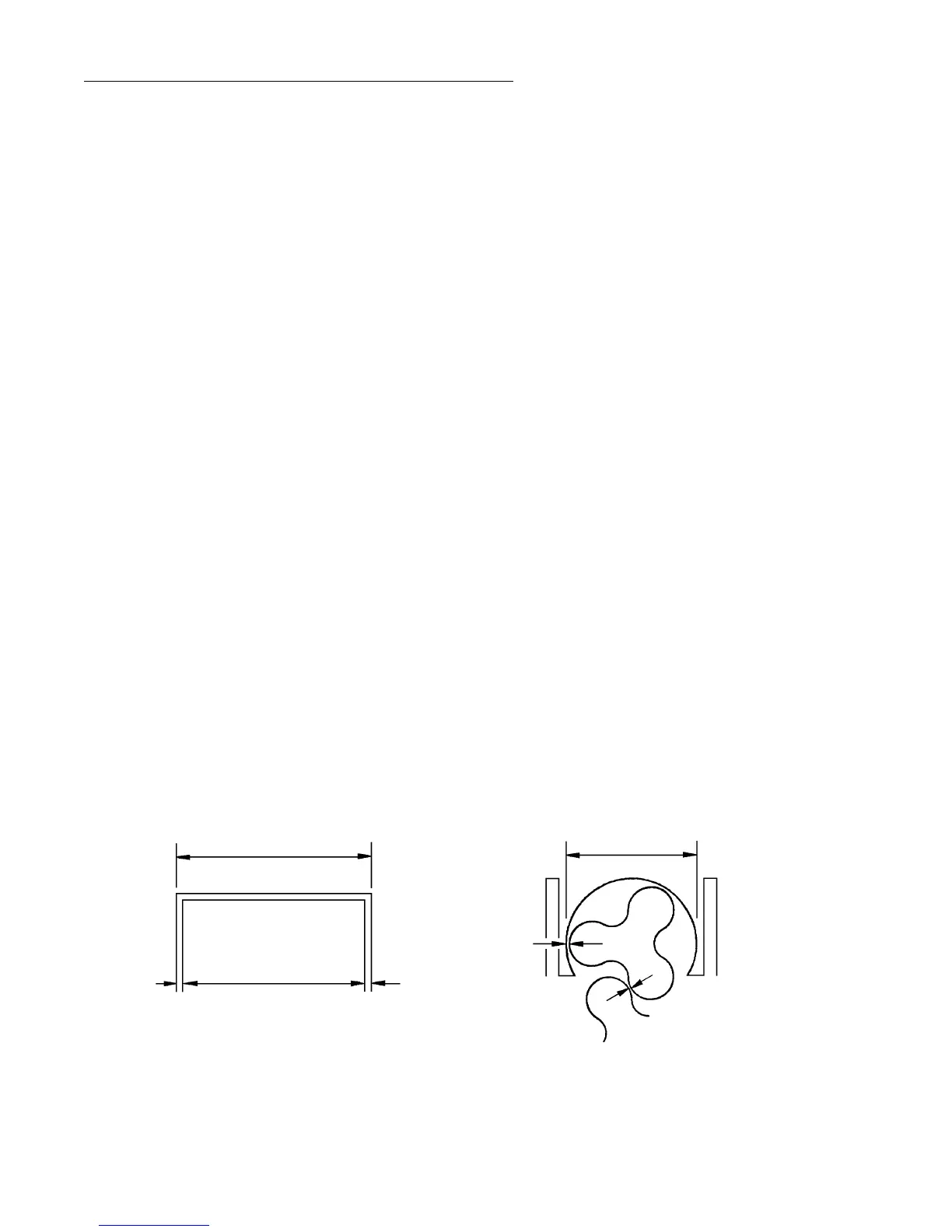

Radial

Clearance

0.018"

0.012"

2.851"

2.854"

Rotorcase Depth

4.263"

4.267"

Rotorcase Dia.

Back

Clearance

0.008"

0.006"

mesh

0.008"

(min. at any mesh position)

Front

Clearance

0.013"

0.009"

Rotor

Length

2.833"

2.835"

Rotor Diameter

4.234"

4.236"

Page 8

Loading...

Loading...