- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

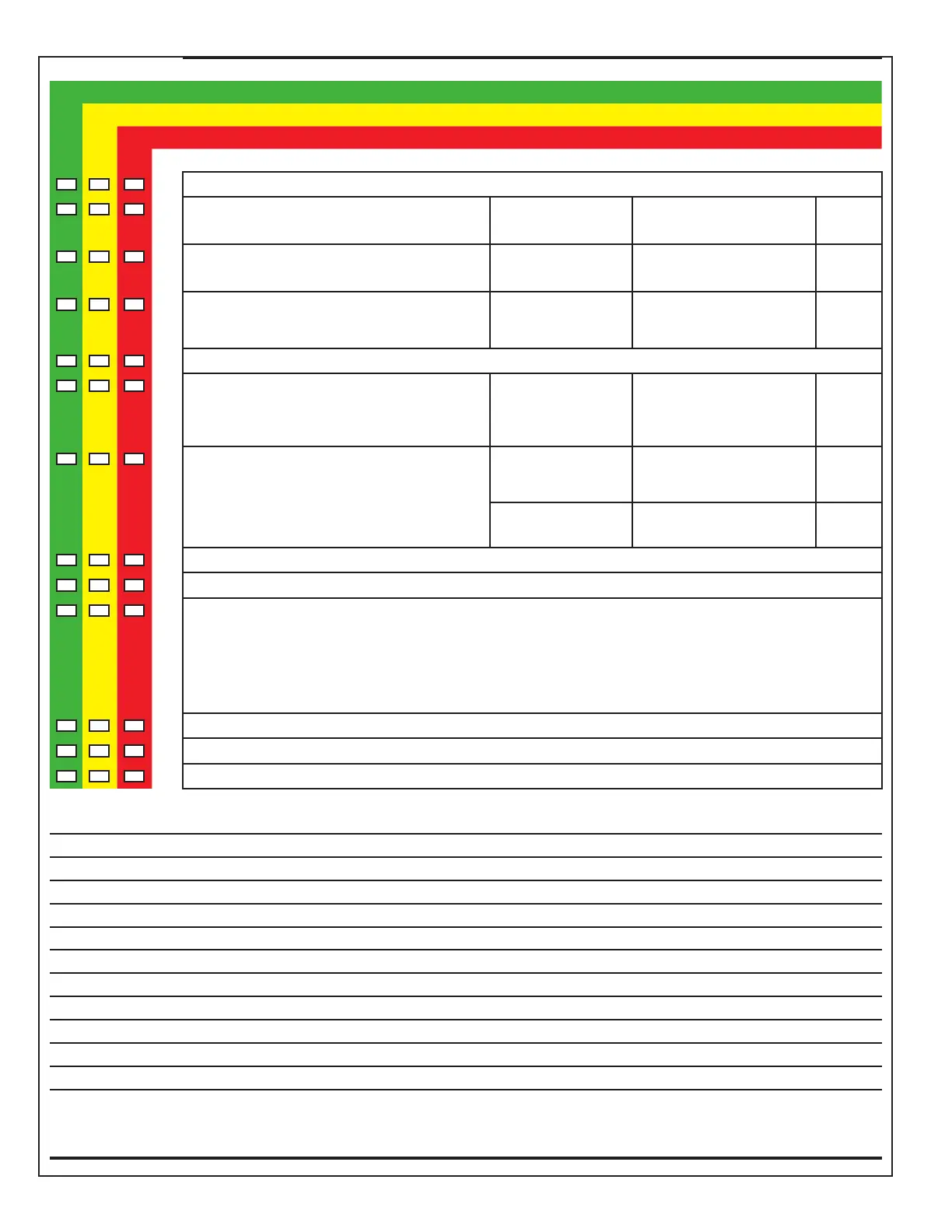

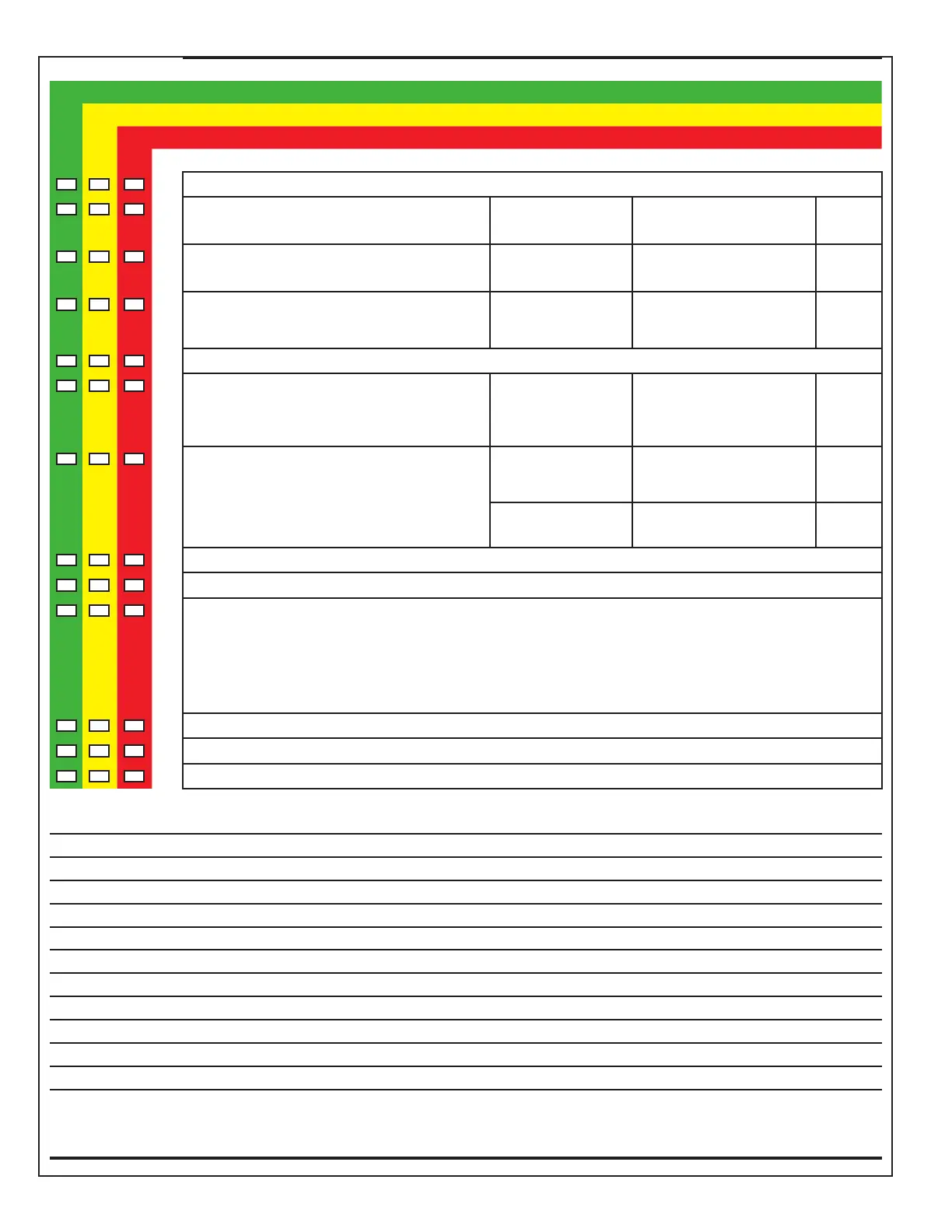

TEAR HERE

CHECKED AND OKAY

MAY REQUIRE FUTURE ATTENTION

REQUIRES IMMEDIATE REPLACEMENT

OPERATIONAL CHECK

1 Run Broiler through Pre-Heat cycle

2 Conrm proper inlet gas supply pressure

a) Refer to Instructions

Measurement after

any adjustments:

“W.C.

mbar”

3 Conrm proper gas pressure to Lower Burner

a) Refer to Instructions

Measurement after

any adjustments:

“W.C.

mbar”

4 Conrm proper gas pressure to Upper IR

Burners

a) Refer to Instructions

Measurement after

any adjustments:

“W.C.

mbar”

5 Inspect IR Burner appearance (Perform proper air adjustment)

6 Ensure Proper Flame Sense Current ( Lower

Module)

a) Greater than 0.7 µA DC (S1)

b) Optimal range when hot is 1.5 µA - 6 µA DC

LOWER

Flame Sense

Measurement:

µA

7 Ensure Proper Flame Sense Current ( Upper

Module)

a) Greater than 0.7 µA DC (S1 & S2)

b) Optimal range when hot is 1.5 µA - 6 µA DC

FRONT

Flame Sense

Measurement:

µA

REAR Flame Sense

Measurement:

µA

8 Check all joints, unions, and compression ttings for gas leakage

9 Check Gas Hose and Quick Disconnect for gas leakage / damage.

10 Ensure all Control functions work properly

a) Button functionality

b) Access to all 4 programming modes

c) Access to Fine Adjustment mode

d) Ensure cook light operates

11 Check discharge function and smoothness of operation

12 Check Loader, Loader Tray, Loader Bracket, and Loader Ramp for smooth loading operation

13 Review monthly cleaning of Flame Sensors and provide supplied brush to Restaurant Manager

Comments:

Technician’s Signature: Manager’s Signature:

Loading...

Loading...