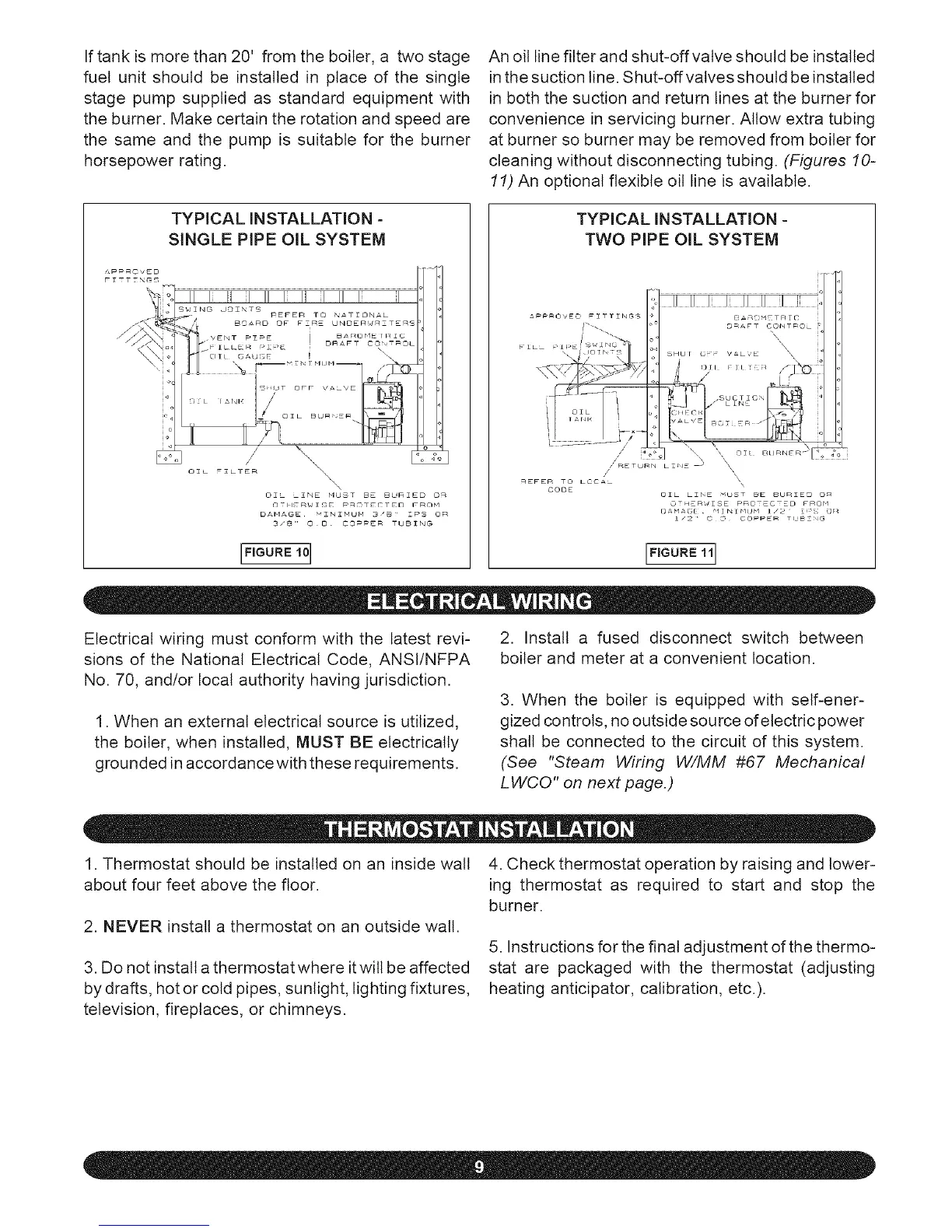

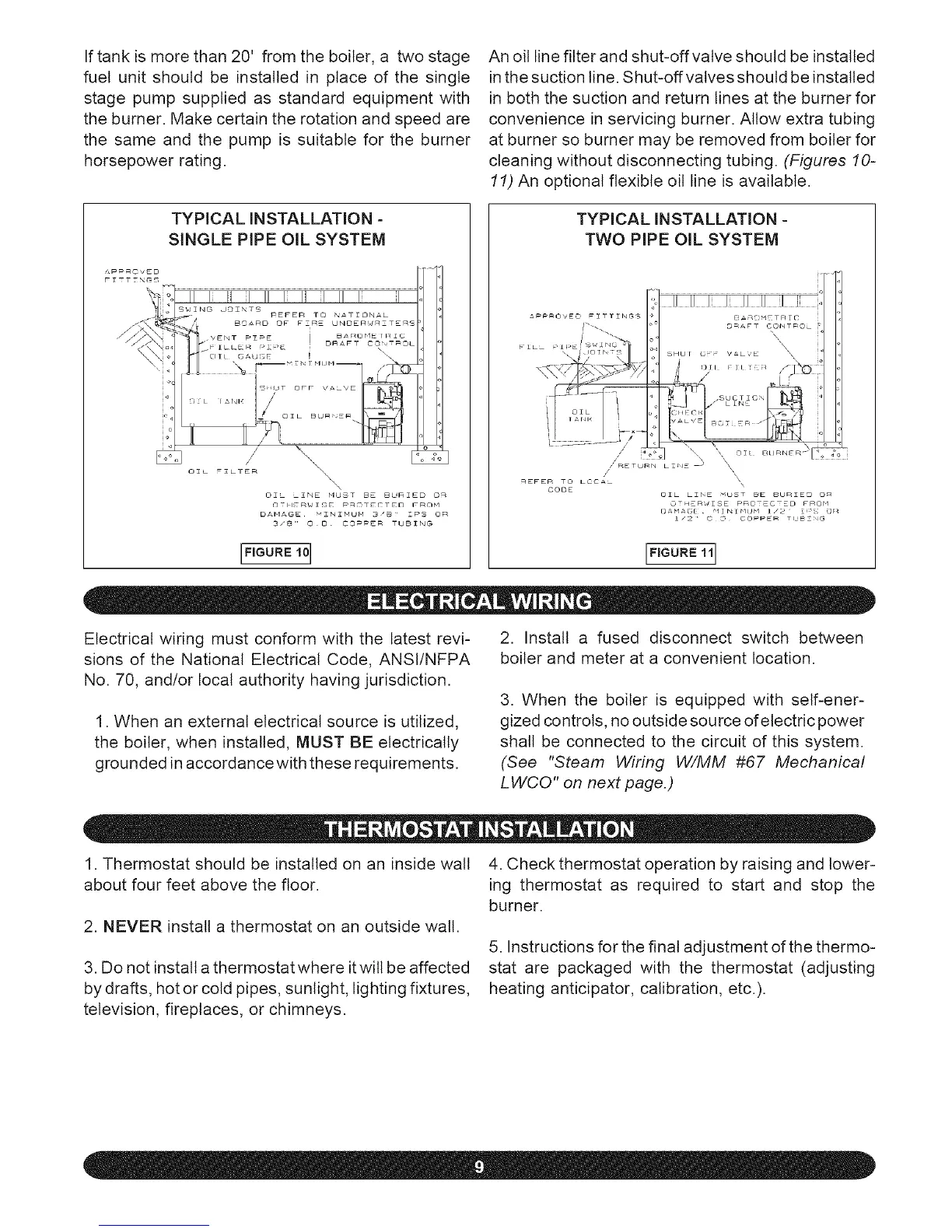

Iftankis morethan20' fromtheboiler,a twostage

fuel unit shouldbe installedin place of the single

stagepump suppliedas standardequipmentwith

theburner.Makecertaintherotationandspeedare

the sameand the pump is suitablefor the burner

horsepowerrating.

Anoillinefilterandshut-offvatveshouldbeinstalled

inthesuctionline.Shut-offvatvesshouldbeinstalled

inboththesuctionandreturnlinesattheburnerfor

convenienceinservicingburner.Allowextratubing

atburnersoburnermayberemovedfromboilerfor

cleaningwithoutdisconnectingtubing.(Figures 10-

11) An optional flexible oil line is available.

TYPICAL INSTALLATION -

SINGLE PIPE OIL SYSTEM

IFIGURE101

TYPICAL INSTALLATION -

TWO PIPE OIL SYSTEM

/

_EFER TO LOCAL

CODE

,\

\

[)AHA( [ "1 I Ni¢ltJbl I/'2

1/2 ' O _ COPPER TtJBZrJG

L''G°"E'll

Electrical wiring must conform with the latest revi-

sions of the National Electrical Code, ANSI/NFPA

No. 70, and/or local authority having jurisdiction.

1. When an external electrical source is utilized,

the boiler, when installed, MUST BE electrically

grounded in accordance with these requirements.

2. Install a fused disconnect switch between

boiler and meter at a convenient location.

3. When the boiler is equipped with self-ener-

gized controls, no outside sou rce of electric power

shall be connected to the circuit of this system.

(See "Steam Wiring W/MM #67 Mechanical

LWCO" on next page.)

1. Thermostat should be installed on an inside wall

about four feet above the floor.

2. NEVER install a thermostat on an outside watt.

3. Do not install a thermostat where itwill be affected

by drafts, hot or cold pipes, sunlight, lighting fixtures,

television, fireplaces, or chimneys.

4. Check thermostat operation by raising and lower-

ing thermostat as required to start and stop the

burner.

5. Instructions for the final adjustment of the thermo-

stat are packaged with the thermostat (adjusting

heating anticipator, calibration, etc.).

Loading...

Loading...