7

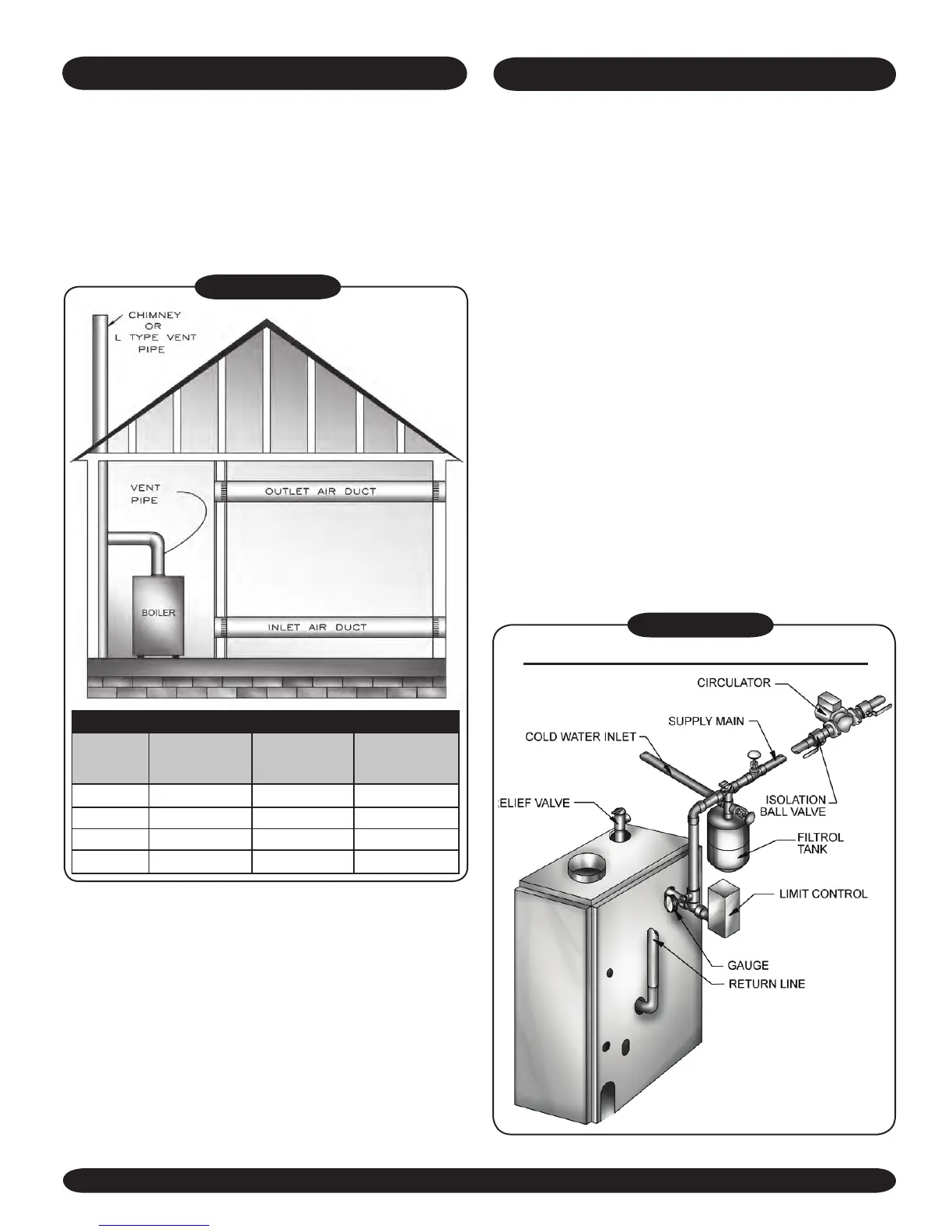

FRESH AIR DUCT CAPACITIES (1 Square inch per 3,000 Btuh)

Fresh Air

Duct Size

100% Free Area

1/4” Wire Mesh

75% Free Area

Metal Louvers

25% Free Area

Wood Louvers

3” x 12” 108,000 81,000 27,000

8” x 8” 192,000 144,000 48,000

8” x 12” 288,000 216,000 72,000

8 ½” x 16” 384,000 288,000 96,000

Figure #3D

FRESH AIR FOR COMBUSTION

a) 1 sq. inch per 3000 Btu per hour of the

total input of all equipment located in the

enclosure, and the front of the appliance

(see Figure #3D).

b) Not less than the sum of the areas of all vent

connectors in the conned space.

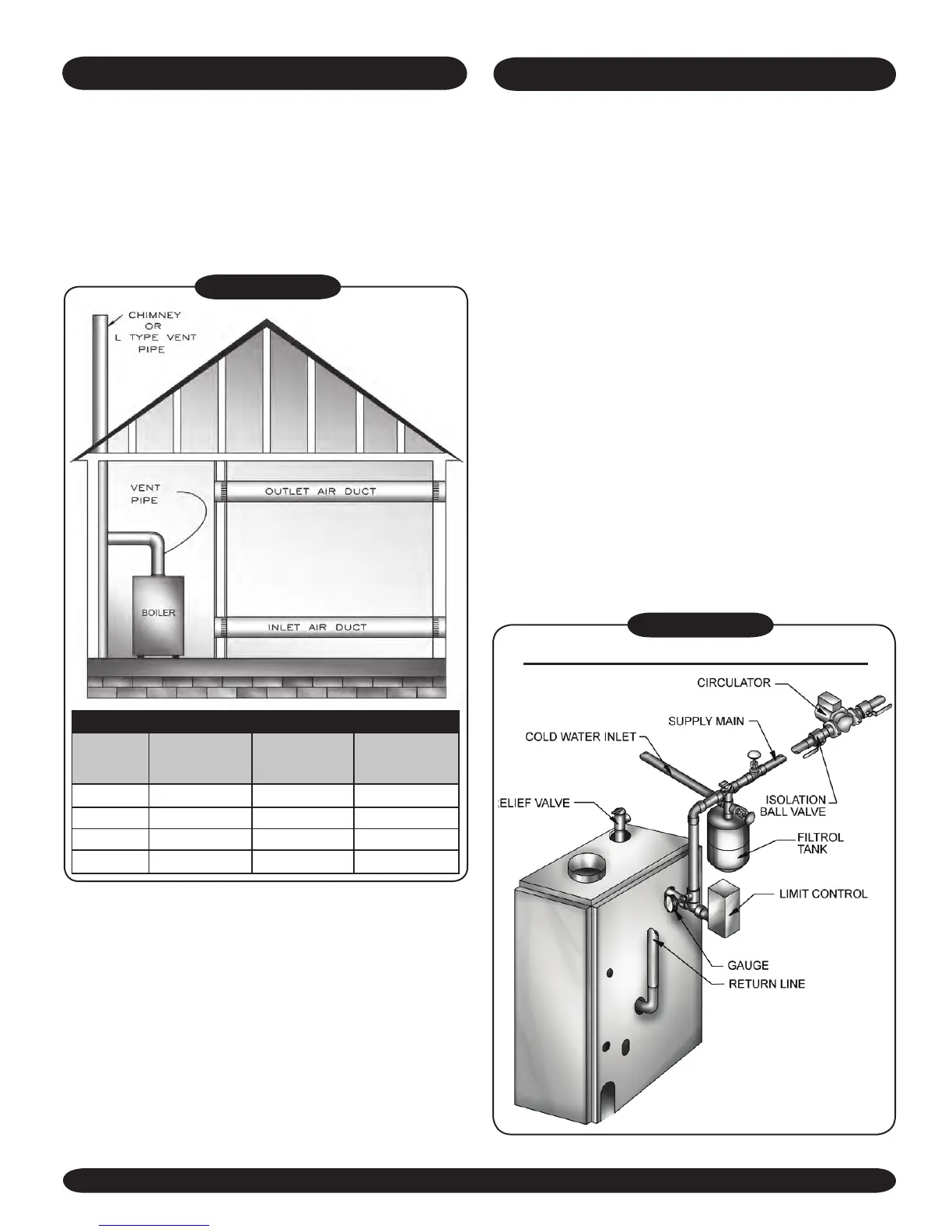

INSTALLATION-SYSTEM PIPING

1. Place boiler in the selected location (as near

chimney as possible). Your boiler is shipped

assembled. You need only to install the circulator,

ball valves the relief valve with a drain line to carry

any water to a drain, and the drain valve.

2. Install Relief Valve on 3/4”pipe nipple in tapped

opening in the left end section. Connect a

drain line of the same pipe size (3/4” to carry

any water away to a drain. No shutoff of any

description shall be placed between the safety

relief valve and the boiler, or on discharge pipes

between such safety valves and the atmosphere.

Installation of the safety relief valve shall conform

to the requirements of the ANSI/ ASME Boiler and

Pressure Vessel Code, Section IV.

3. Install Drain Valve on lower left side of boiler

as marked.

4. Install Temperature and Pressure Gauge into ¼”

bushing threaded in tee furnished with supply

piping (see Figures #4 and #5)

FORCED HOT WATER TYPICAL PIPING

Figure #4

Loading...

Loading...