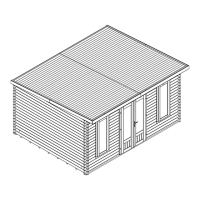

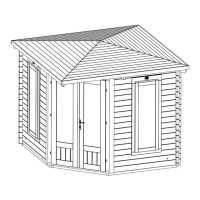

This document serves as an installation manual for the Dunster House TERMINATOR 5.0m x 3.0m (45mm) Log Cabin, model E10-5030TM-45. It provides comprehensive instructions for assembling the log cabin, along with important information regarding the nature of wood, treatment, preparation, and troubleshooting.

The log cabin is designed as a timber structure, primarily for outdoor use, offering a versatile space that can serve various purposes such as a garden office, workshop, or leisure room. Its construction relies on interlocking log walls, a common method for timber buildings, which allows for a relatively straightforward assembly process when following the provided guidelines.

Usage Features:

The log cabin is intended to be a robust and functional outdoor building. Key usage features include:

- Customizable Layout: The manual highlights that the layout of doors and windows can be changed by installing relevant logs on opposite sides of the wall, offering flexibility in design to suit individual preferences or site requirements. However, certain top wall logs (ASAT and XN.RL) have a fixed orientation with their top angle sloping towards the rear of the cabin.

- Natural Wood Aesthetics: Constructed from soft wood, the cabin embraces the natural characteristics of timber, including knots, knotholes, cracks, warping, and colour variations. These are considered inherent properties that contribute to the cabin's natural character.

- Optional Enhancements: The manual mentions optional features such as roof insulation and additional doors/windows, allowing users to customize the cabin for improved thermal performance or increased accessibility and natural light. These optional components are installed after the main cabin structure is complete.

- Ventilation: Apex vents are included to ensure proper airflow within the cabin, helping to prevent moisture buildup and maintain a comfortable internal environment. These vents feature a circular slatted grill on the outside and a square meshed grill on the inside.

Maintenance Features:

Proper maintenance is crucial for the longevity and performance of the log cabin. The manual provides several key maintenance-related instructions:

- Timber Treatment: The cabin requires treatment with a suitable timber treatment once construction is complete. It is recommended to use a treatment that contains a water repellent, or apply one separately. Periodic re-application of treatment is necessary. Users are advised not to apply treatment too thickly, as this can 'glue' the logs together and restrict their natural movement, which is essential for the timber's inherent properties.

- Storage of Components: Prior to assembly, all components should be stored in a cool, dry place, away from direct contact with the ground, sunlight, and moisture. For prolonged storage, timbers should be kept straight and well-supported to prevent twisting.

- Addressing Wood Imperfections: The manual acknowledges that timber may have imperfections like knots, cracks, or warping. It provides guidance on how to handle twisted/warped timber during installation, suggesting techniques like using clamps, hitting blocks, and strategic placement of warped logs to ensure structural integrity. Minor damage, such as a broken notch, can be remedied by pre-drilling, screwing, and gluing.

- Door and Window Alignment: Wood is a natural material that will 'move' over time, so windows and doors are designed to 'realign'. The manual provides detailed troubleshooting steps for misaligned door locks and stuck doors, including adjusting hinges and repositioning receivers. It also explains how to secure door and window frames to allow for vertical movement while maintaining horizontal position.

- Storm Braces: Storm braces are installed after the roof is fitted to enhance the cabin's structural stability. These braces are designed with slotted holes at the bottom to allow for vertical movement of the bolts, accommodating the natural movement of the timber.

- General Checks: Regular checks during construction are emphasized, including ensuring the base is level and square, and verifying wall levels every 4 layers of logs. This proactive approach helps prevent larger issues later on.

- Replacing Damaged Parts: While the manual states that Dunster House Ltd will not freely replace parts damaged due to neglectful workmanship during construction, replacement parts are available for purchase. For components with features like splits or knot holes that might cause an issue, customers can send a photograph for assessment.

The manual also stresses the importance of a level and stable load-bearing foundation, as failure to do so can lead to installation issues and diminish the cabin's integrity. It provides a general build summary, outlining the sequence of steps from laying bearers to installing optional guttering, ensuring a systematic approach to construction. Tools required for assembly are also listed, ranging from basic hand tools to power tools, with a strong recommendation to pre-drill holes for all screws and bolts to prevent timber splitting.

Loading...

Loading...