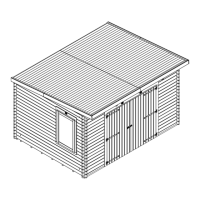

This document is an installation manual for the Dunster House TERMINATOR 3.5m x 2.5m (45mm) Log Cabin, model E10-3525TM-45. It provides comprehensive instructions for assembling, maintaining, and troubleshooting the log cabin.

Function Description

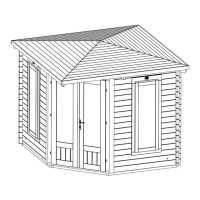

The Dunster House TERMINATOR log cabin is a wooden structure designed for outdoor use, likely as a garden office, storage shed, or recreational space. The manual guides users through the entire construction process, from preparing the base to installing the roof, doors, windows, and various trims and braces. It emphasizes the importance of proper assembly to ensure the structural integrity and longevity of the cabin.

Important Technical Specifications

The cabin's dimensions are 3.5m x 2.5m, with a wall log thickness of 45mm. The manual provides a detailed parts list, including dimensions (thickness, width, length) for all wooden components, nails, screws, bolts, and accessories.

-

Wooden Parts:

- Bearers (Pressure treated): 32mm (Thk) x 47mm (Width) x 3350mm (Lng). 9 pieces.

- Floor Board T&G: 19mm x 97mm x 2260mm. 37 pieces.

- Roof Board T&G: 19mm x 97mm x 1745mm. 62 pieces.

- Wall Logs (various lengths): 44mm x 121mm, ranging from 560mm to 3490mm in length. Includes standard wall logs, bottom wall logs (64.5mm width), top wall logs (140mm width for ASAT, 121mm for XN.RL), and a specific "Wall Log F" (44mm x 121mm x 1695mm).

- Apex: 44mm x 346mm x 2790mm. 2 pieces.

- Purlin: 45mm x 140mm x 2815mm. 3 pieces.

- Eaves Edging: 19mm x 70mm x 2000mm. 2 pieces.

- Fascia Board: 19mm x 120mm, in 2000mm and 3000mm lengths. 4 pieces.

- Storm Brace: 19mm x 38mm x 1960mm. 4 pieces.

- Trim: 19mm x 38mm x 1960mm. 18 pieces.

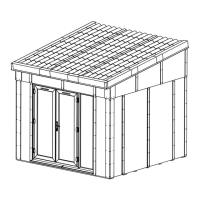

- Doors: E10 - NARROW DOUBLE DOOR - 45 (HT 2020mm, WD 1280mm, WALL THICKNESS 44mm). 1 piece.

- Windows: E10 - NARROW WINDOW - 45mm (HT 1605mm, WD 620mm, WALL THICKNESS 44mm). 1 piece.

-

Nails: 40mm nails (402 pieces).

-

Screws: 70mm (52 pieces), 50mm (94 pieces), 35mm (72 pieces), 20mm (8 pieces).

-

Bolts: M6 Washer (16 pieces), M6 x 80mm Bolt (8 pieces), M6 Wing Nut (4 pieces), M6 Nut (4 pieces).

-

Accessories: Vent Set (2 pieces), Installation Manual (1 piece), Door Handle Set and Accessories (1 piece), Window Handle Set and Accessories (1 piece).

The minimum overall base dimension for the log cabin should be 100mm bigger than the external dimensions of the cabin to ensure a stable foundation.

Usage Features

- Modular Construction: The log cabin is built using interlocking wall logs, which are stacked layer by layer.

- Reversible Layout: The layout of doors and windows can be changed by installing relevant logs on the opposite side of the wall, offering flexibility in design. However, ASAT and XN.RL logs (top wall logs) cannot be reversed and must have their top angle sloping towards the rear.

- Door and Window Installation: Windows are pre-assembled, while door frames come in separate parts for protection during transport. Frames are secured with 35mm hex nut screws and washers through slotted holes, allowing for natural movement of the wood.

- Roofing Options: The manual details the installation of roof boards, roof edge reinforcement trims, and roof felt. Optional roof insulation can be installed prior to felt.

- Storm Braces: Four storm braces are included to enhance structural stability, installed internally or externally, and attached to the apex or top wall log. They are designed to allow vertical movement to accommodate timber expansion/contraction.

- Floor Installation: Floor boards are installed centrally between front and rear walls, with expansion gaps (5mm for 45mm walls, 16mm for 34mm walls, 22mm for 28mm walls) between side walls and floor boards. Optional floor insulation can be installed.

- Apex Vents: Circular slatted grills for the outside and meshed grills for the inside are provided for ventilation.

- Troubleshooting: The manual includes sections for common issues like misaligned door locks, stuck doors, and damaged timber, offering solutions and guidance on when to contact customer services.

Maintenance Features

- Timber Treatment: The log cabin's timber is untreated (except for bearers) and requires a suitable timber treatment with water repellent once built. Periodic re-application is necessary. Care must be taken not to apply treatment too thickly to avoid "gluing" logs together and restricting natural movement.

- Storage: Prior to assembly, components should be stored in a cool, dry place away from direct contact with the ground, sunlight, and moisture to prevent twisting and warping.

- Timber Properties: The manual acknowledges that wood is a natural material and may have knots, knotholes, cracks, warping, and imperfections. These are considered inherent properties and do not necessarily require replacement unless they compromise structural stability. Tips are provided for installing twisted/warped timber.

- Door and Window Realignment: Due to the natural movement of wood, windows and doors are designed to be "free to realign." The installation method allows for vertical movement while maintaining horizontal position. Instructions are provided for adjusting door sashes and bolts if they do not line up or close properly.

- Pre-drilling: Throughout the assembly process, pre-drilling pilot holes (3mm for screws, 8mm for bolts) is emphasized to prevent timber splitting.

- Cleaning: Sap, a normal occurrence in timber, can be gently cut off with a sharp knife once dry.

- Sealing: Silicone can be used to seal the wind brace to the roof.

Loading...

Loading...