Operating manual part II

© 2013 Dürkopp Adler AG II-9

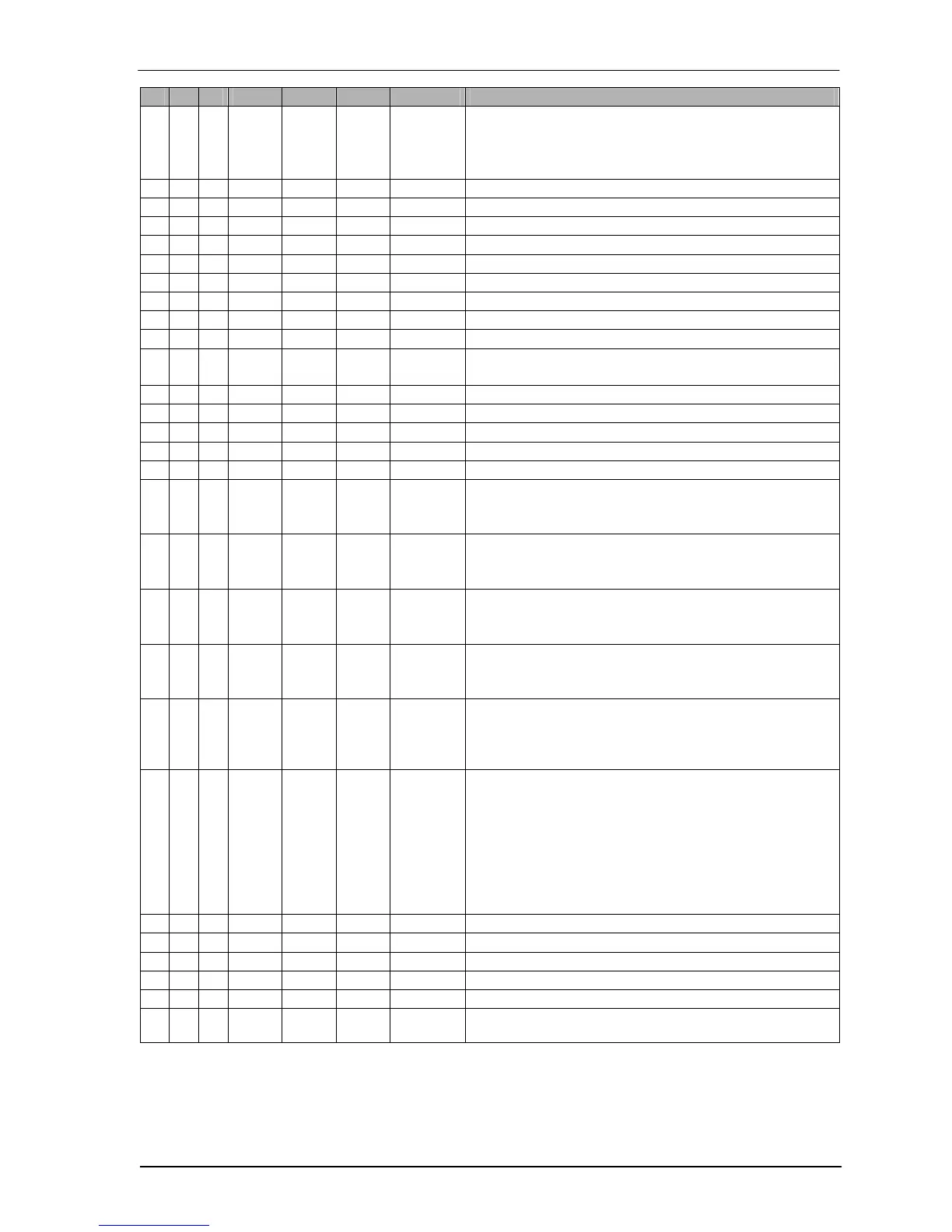

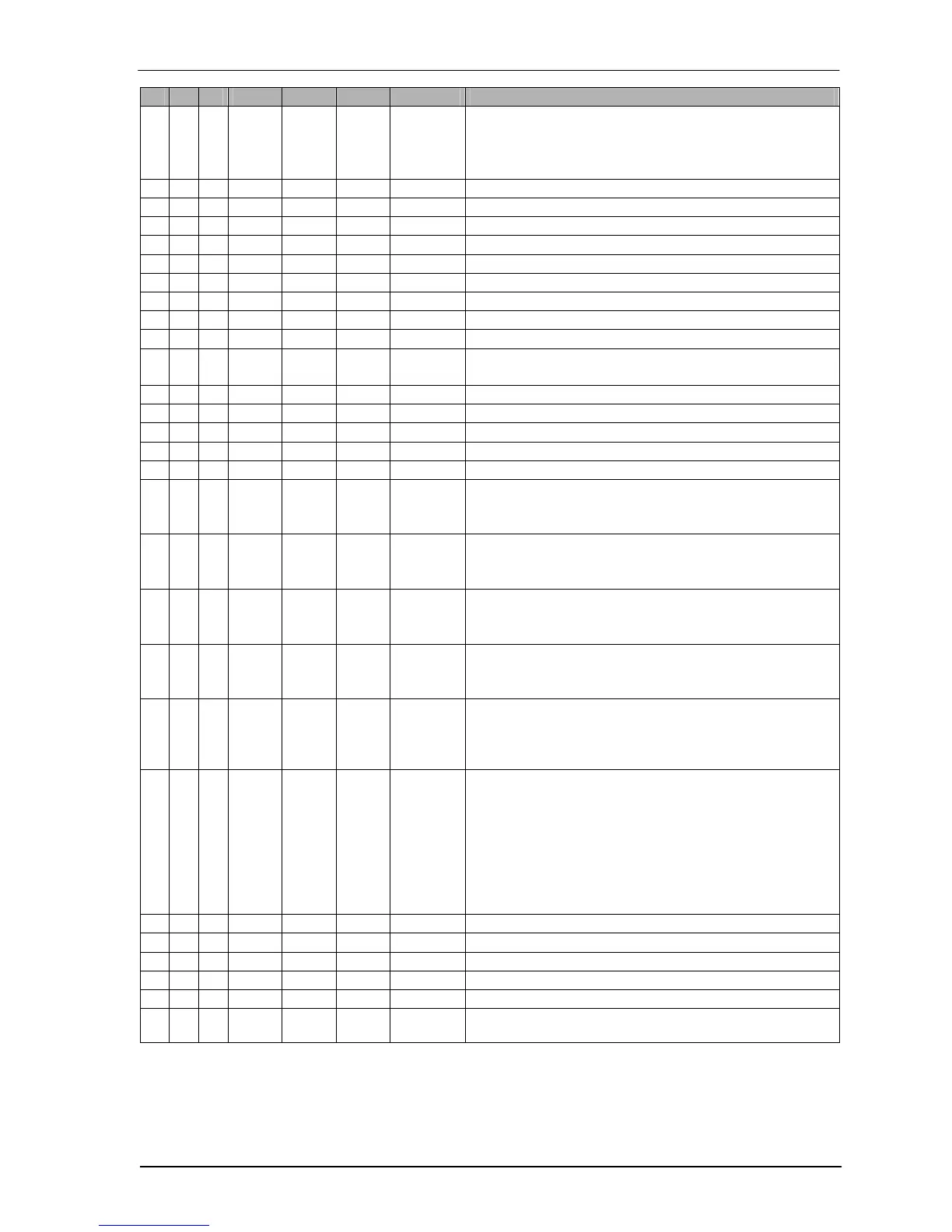

L C P Min Max Preset Unity Description

t 08 06 0 2 1 - Motor brake at the normal stop

0 = Brakes for the duration of t0809;

1 = Brake durably actively at the stop

2 = Position will be hold permanently

t 08 07 0,1 6,0 3,0 A Holding current at the machine stop

t 08 08 0 255 40 - Reaction rate at changes of the needle position

t 08 09 0 999 200 ms Period of the motor brake

t 08 10 - - - - Setting the reference position

t 08 11 - - - - Setting the needle positions

t 08 12 0 359 120 ° Lower needle position (Position 1)

t 08 13 0 359 329 ° Thread lever up position (Position 2)

t 08 14 0 359 350 ° Direction finder position

t 08 15 0 359 245 ° on threading position

t 08 19 1 9999 650 - Pulley ratio=

(diameter motor / diameter machine) * 1000

t 08 20 - - - - Calibrating pedal

t 08 21 12 64 24 Steps Number of speed steps of the pedal

t 08 22 0 4 3 - Speed curve

t 08 23 10 255 90 ms Debouncing of the position-1

t 08 24 5 255 15 ms Debouncing of the position-2

t 08 25 0 1 0 - Choice of the pedal

0 = Analogous;

1 = Digital

t 08 26 0 1 0 - Invert the digital signal of the pedal

0 = No;

1 = Yes(Efka-Pedal with adapter )

t 08 30 0 1 1 - Shows the machine speed

0 = No;

1 = Yes

t 08 31 0 1 0 - Shows the current needle position

0 = No;

1 = Yes

t 08 32 0 1 0 - The Needle will move to the upper needle position if the

energy is on and the pedal was used.

0 = No;

1 = Yes

t 08 33 0 6 0 - Output of position signals

0 = No output;

1 = pos1;

2 = pos2;

3 = pos1 & pos2;

4 = machine running (ML);

5 = machine running (ML) & pos1;

6 = machine running (ML) & pos2;

t 08 34 0 255 0 ° Angle for the length of pos1

t 08 35 0 255 0 ° Angle for the length of pos2

t 08 36 10 9999 10 rpm Speed for the activation of motor running signal

t 08 40 500 9999 1500 rpm Speed limitation DB3000

t 08 41 500 9999 1800 rpm Speed limitation DB2000

t 08 50 10 500 180 rpm Speed for single stitch functions(For example half stitch and

full stitch)

Loading...

Loading...