Initial Start-up

1) Remove the LH Front Access Panel, and ensure

that there is sufficient Oil in the Oil Reservoir.

Refer to the ‘Lubrication’ section (page 8) in this

manual for proper type and level of Oil.

2) Do a visual inspection of the Unit, and ensure

that all fasteners are sufficiently tightened. This

must be done, as some fasteners may become

loose in transit.

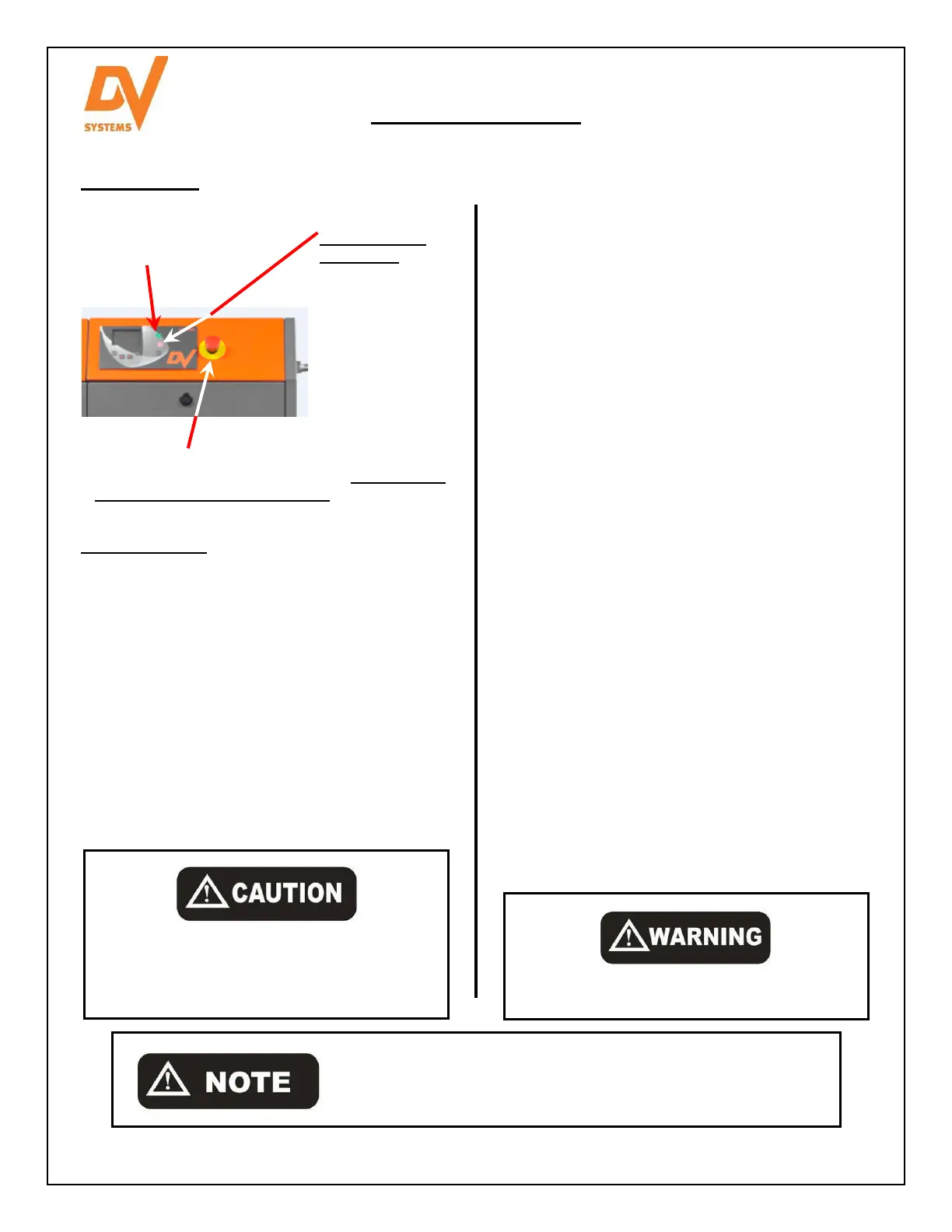

3) Place the Fused Disconnect / Breaker in the ‘On’

position. Check that there is power to the

Controller

4) During normal operation of the Unit, keep the

Access Panels closed at all times.

5) Ensure the Ball Valve on the Unit is closed, press

the ‘Start’ Button, and run the Unit up to

maximum pressure. The Unit will run up to

approx. 145 psi (10bar), at which point the Motor

will continue to run but not compress air.

6) Once the Unit reaches 145 psi (10bar), it will idle

for 5 minutes and shut off. For VSD units, the

unit will idle for 2 minutes and shut off.

7) Open the Ball Valve slightly and allow the air to

bleed from the Tank. Once the pressure reaches

approx 125 psi (8.6bar), the Unit will start and

begin to compress air after a short delay. For

VSD units, this pressure is 135 psi (9.3bar).

8) Measure the amp draw as the Unit reaches

maximum pressure.

9) Close the Ball Valve, allow the Unit to reach

maximum pressure, idle, and shut off. Once off,

check the various fittings etc inside the Cabinet to

ensure there are no internal leaks.

10) Once you are confident that there are no internal

leaks, the Unit will be ready for normal use.

11) Register the Unit to Activate the Warranty by

completing the Warranty Registration form at:

gdg.gardnerdenver.com/DV-Rotary-Warranty

Loading...

Loading...