2.3 Maintenance and Repair Qualification

Maintenance and repair of the machine must onl be made b a Dnamic Diamond Tooling

certified service technician or authoried representative

2.4 Electrical Safety

The electrical power source must be euipped with fuses as specified in the “Electrical

Specifications” Table 11 All cables must be marked and rated according to the fuses

used

ever connect the machine to a power source that does not provide protective earth

ork on electrical euipment should onl be undertaken b a skilled electrician or b a trained

person under the supervision of a skilled electrician as well as in accordance with local electrical

regulations

se etension cables that are used for etending the main cable and are sied and marked in

accordance with the overall power consumption of the machine

se tools that are insulated against electricit

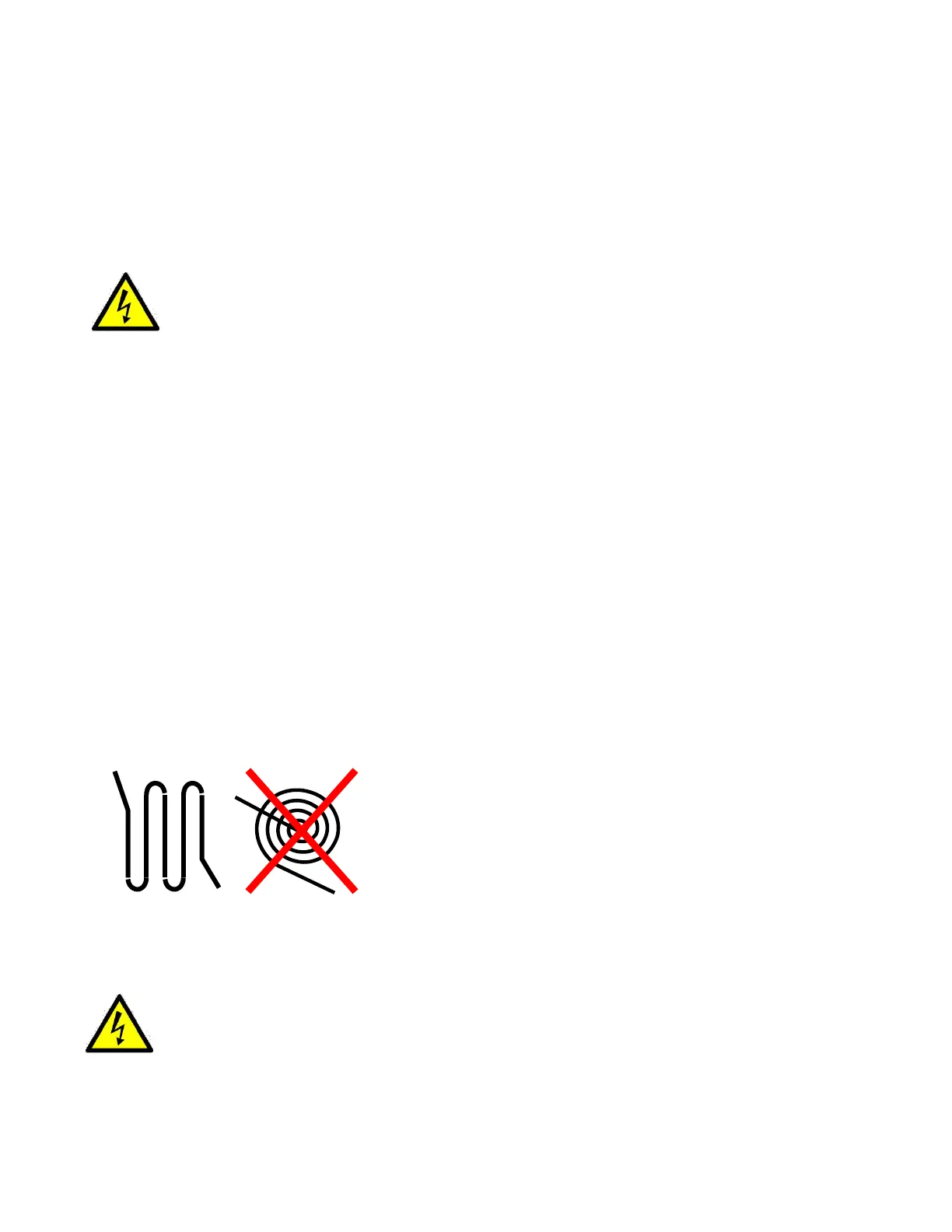

2.4.1 Electrical Cables

nl use cables that are marked and rated according to the specifications in “Electrical

Specifications”Table 11. Do not use ecessive length of electrical cables ever la the cable

in a loop when operating the machine this will cause the cable to heat up and ma cause a fire

See Figure 2-1 for eplanation

Figure 2-1 ecommended wa to handle ecessive cable length

2.4.2 Using a Generator

It is imperative to ensure that the Generator oltagehase Selector switch is correctl

matched to the machine voltagephase as shown in the “Electrical Specifications”

Table 11

Loading...

Loading...