3CA 250/252/262 W1065EN2

FITTING

Fitting must be done in a workshop environment, on a

clean, level base and with lifting capabilities for at least

1000 kg (2,200 lbs). Ensure at least 3 meters (120") of

free space in front of the machine (see overleaf).

Make sure the drum is well cleaned.

Estimated time for this retrofitting is about 6 hours.

The following tools are required:

- Lift, at least 1000 kg (2,200 lbs)

- Screw clamps

- Drilling machine

- Drill, 22 mm (7/8")

- Hexagonal socket wrench 38 25 71

- Torque wrench

- Socket wrenches

Before modifying

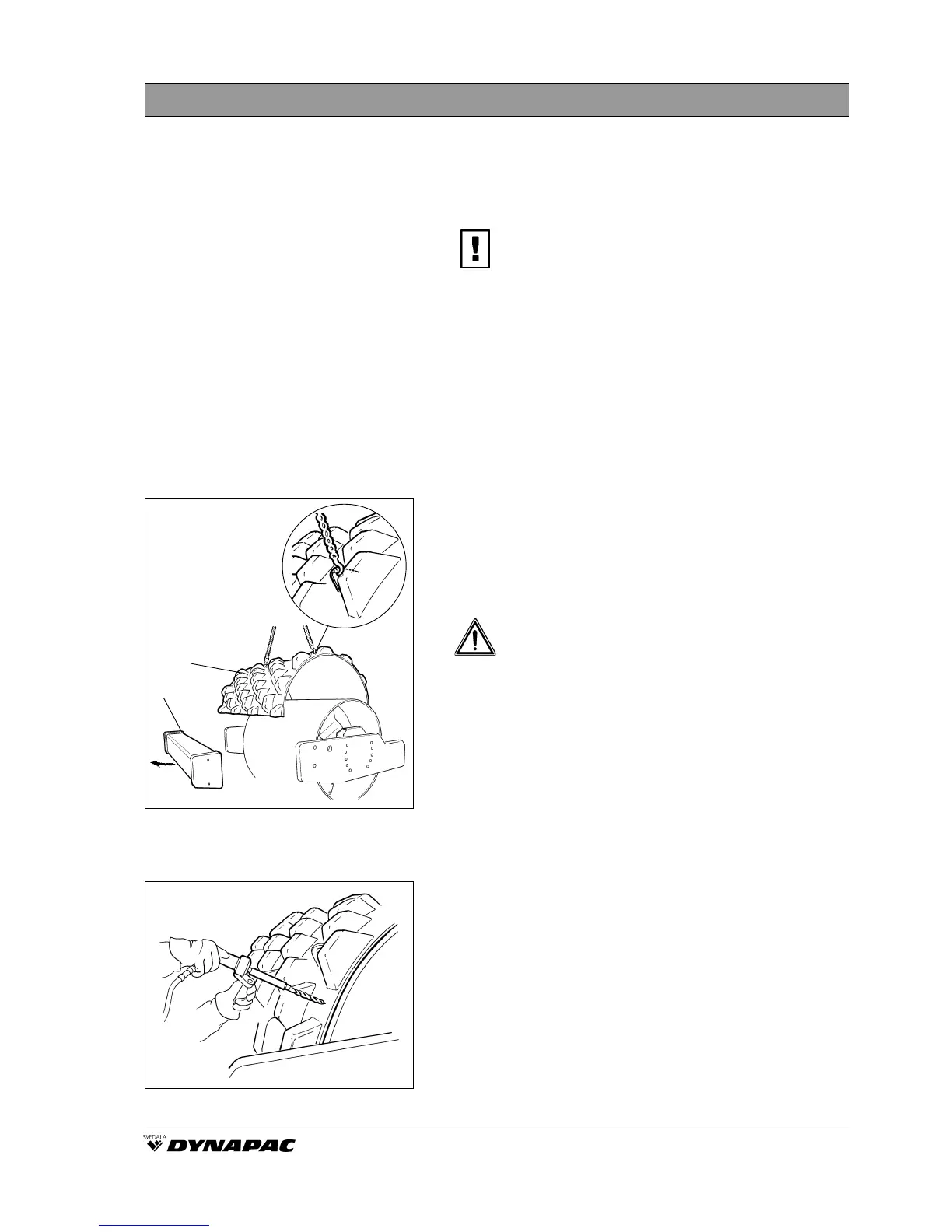

1. Dismantle the front transverse beam (1).

2. Lift the first pad half (2) and place it on top of the

drum. Align the pad half with the outer edges of the

drum. Fix the pad half with screw clamps against

the drum shell.

Keep well clear of the hoisted object. En-

sure that hoisting hooks are securely

anchored.

1

Fig. 1 Fitting the pad half

1. Transverse beam

2. Pad half

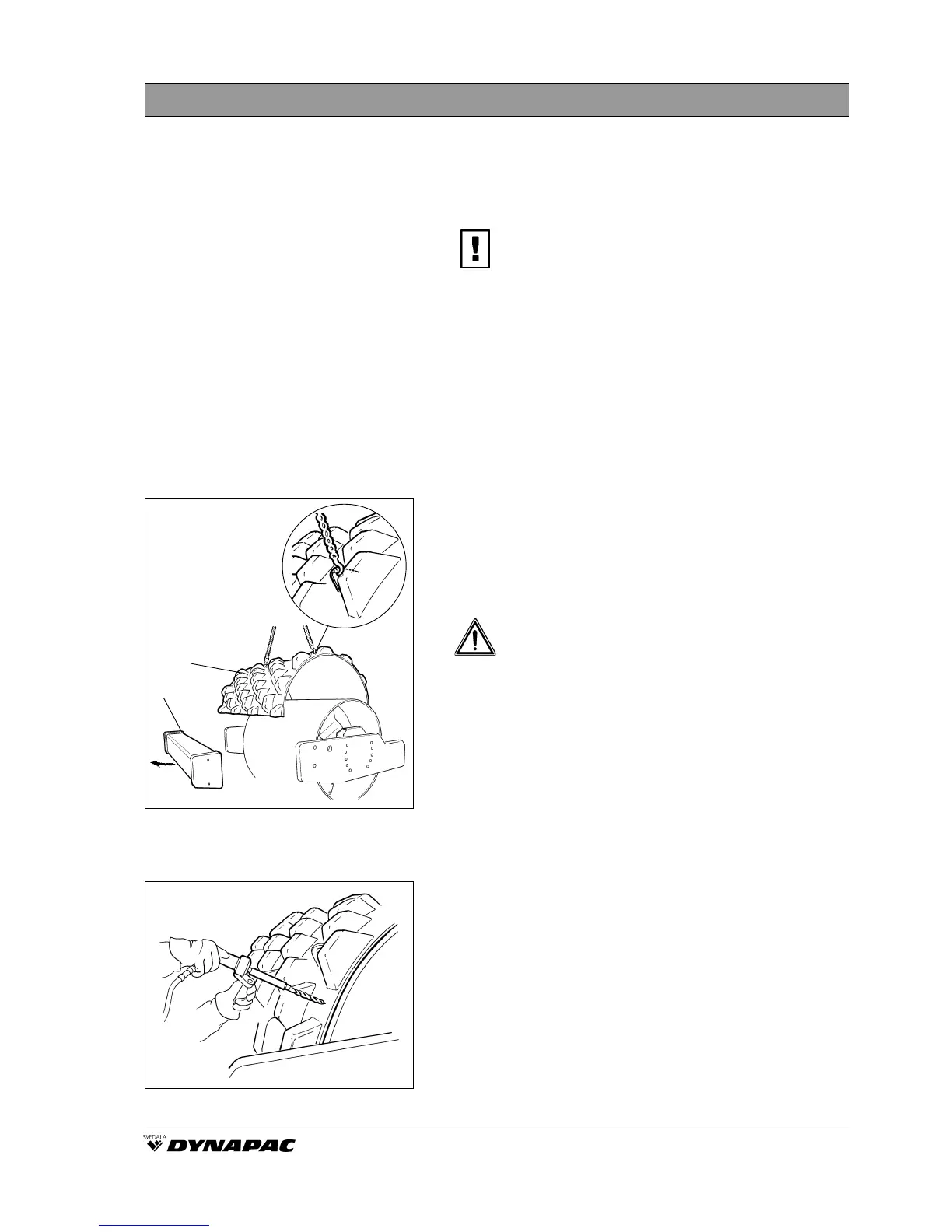

3. Drill two 22 mm (7/8") holes through the pad shell

and the drum shell. Use the two 8 mm pre-drilled

holes as position guides.

Fig. 2 Drilling through holes

2

Loading...

Loading...