5CA 250/252/262 W1065EN2

FITTING

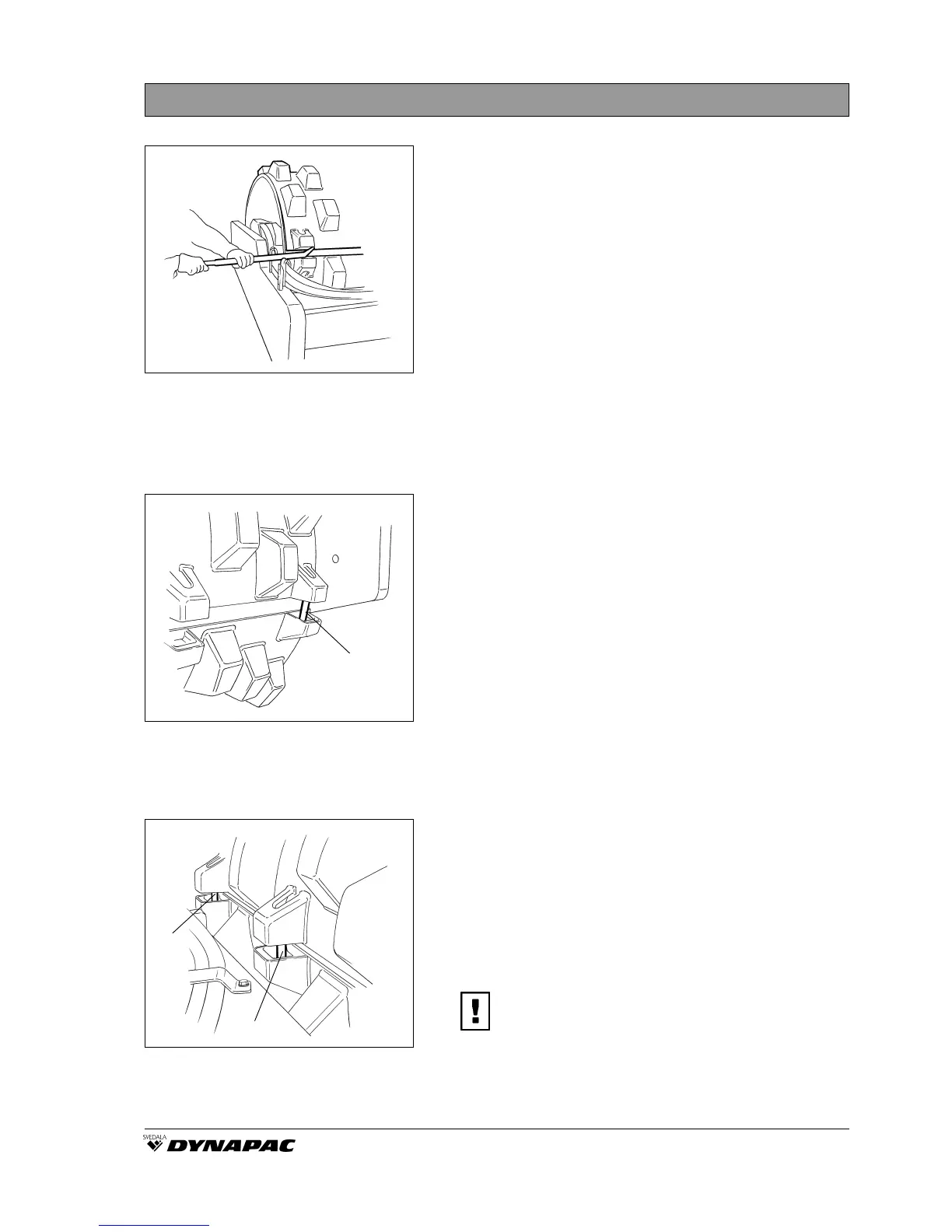

Fig. 6 Clearance between pad halves

Fig. 7 Pad halves

13. Fitting bolts x4

7. Distribute the clearance between the pad shells.

This is to ensure that the bolts fit properly.

8. Lubricate the four fitting bolts (13) and fit them with

the head upward in the outer positioned pads on

both sides.

9. Tighten the two pad halves together. Ensure that the

clearance is evenly distributed, about 25 mm (1"),

between the halves when you tighten the bolts (use

tool 38 25 71 as a counter-support).

10. Drill two 22 mm (7/8") holes through the pad shell

and the drum shell. Fit the two M20 bolts.

13

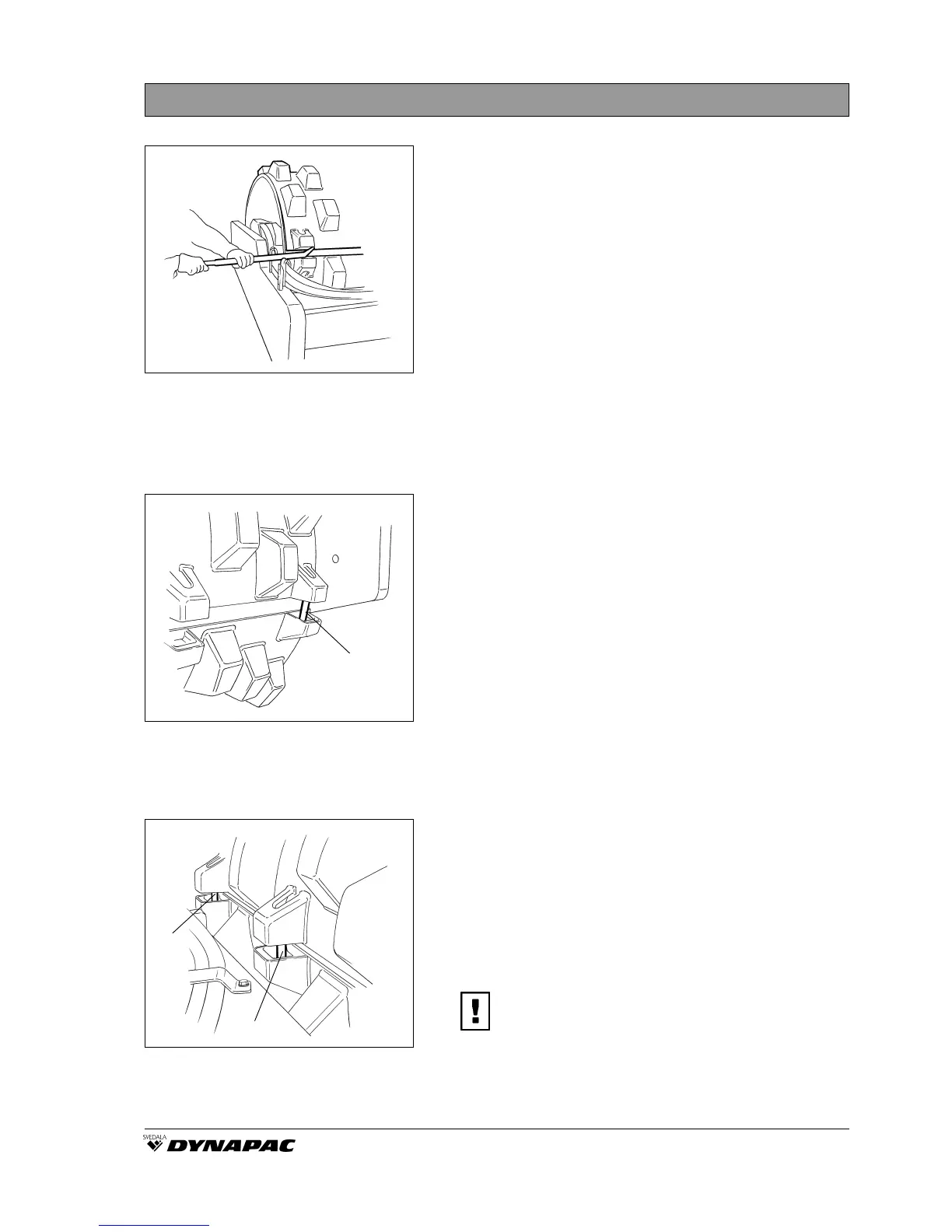

Fig. 8 Fitting the pad half

3. Bolts

11. Fit the two middle bolts (3) with the head upwards

and torque-tighten them (item 3 in drawing 38 22 20).

Then unscrew the outer fitting bolts and replace

them with M20x140.

12. When all four bolts are torque-tightened according

to drawing 38 22 20, reverse the machine half a turn

of the drum to gain access to the second joint.

Repeat according to the above.

Ensure that clearance is equal between the

pad shells. Use tool 38 25 71.

Save the tool and the four tightening bolts for future

use.

3

3

Loading...

Loading...