Rev. 01/11 - 2.15 - TFXL-X

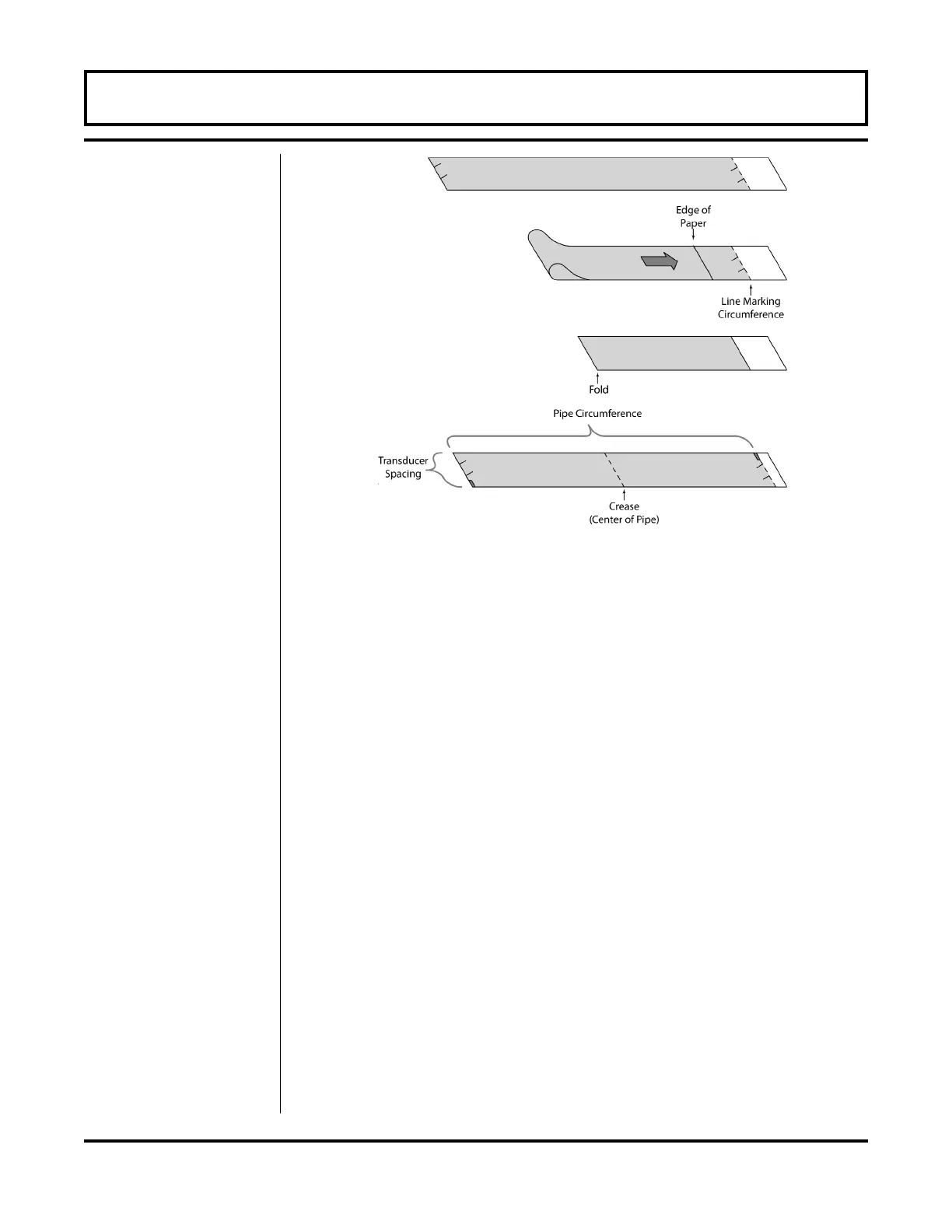

the template back around the pipe, placing the beginning of the

paper and one corner in the location of the mark. Move to the

other side of the pipe and mark the pipe at the ends of the

crease. Measure from the end of the crease (directly across the

pipe from the first transducer location) the dimension derived in

Step 2, Transducer Spacing. Mark this location on the pipe.

4. The two marks on the pipe are now properly aligned and

measured.

If access to the bottom of the pipe prohibits the wrapping of the

paper around the circumference, cut a piece of paper to these

dimensions and lay it over the top of the pipe.

Length = Pipe O.D. 1.57

Width = Spacing determined on page 2.6

Mark opposite corners of the paper on the pipe. Apply

transducers to these two marks.

5. For DTTN transducers, place a single bead of couplant,

approximately ½ inch (12 mm) thick, on the flat face of the

transducer. See Figure 2.2 on page 2.9. Generally, a silicone-

based grease is used as an acoustic couplant, but any grease-

like substance that is rated to not “flow” at the temperature that

the pipe may operate at, will be acceptable.

PART 2 - TRANSDUCER INSTALLATION

Figure 2.12

Bisecting the pipe circumference

Loading...

Loading...